Gas operated firearm action delay device

a delay device and firearm technology, applied in the direction of weapons, ammunition loading, firing/trigger mechanism, etc., can solve the problems of sacrificing accuracy, pistons adding weight to the rifle, and delay devices of semi-automatic rifles being required by mechanical systems, etc., to achieve increased accuracy and high fire rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

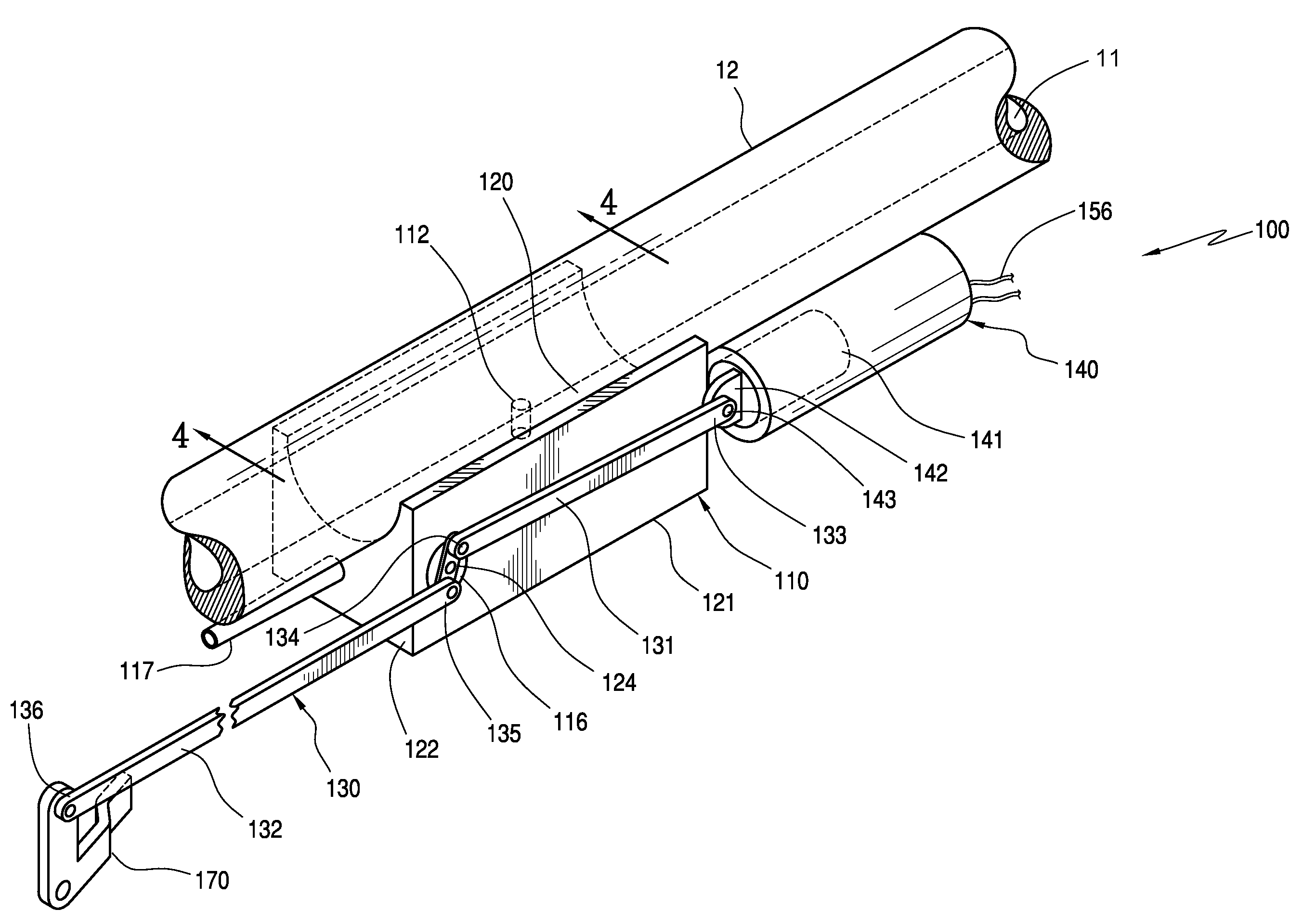

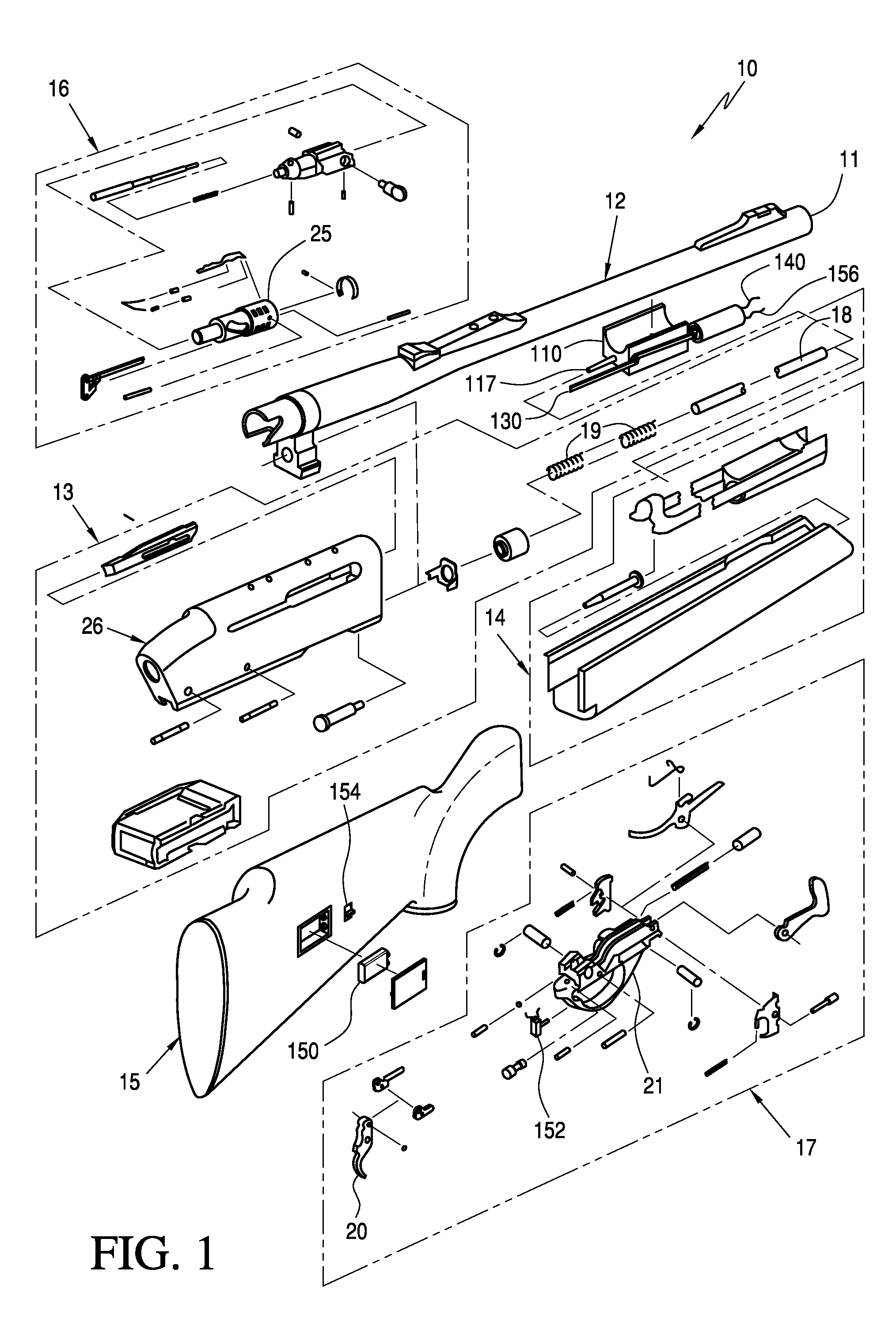

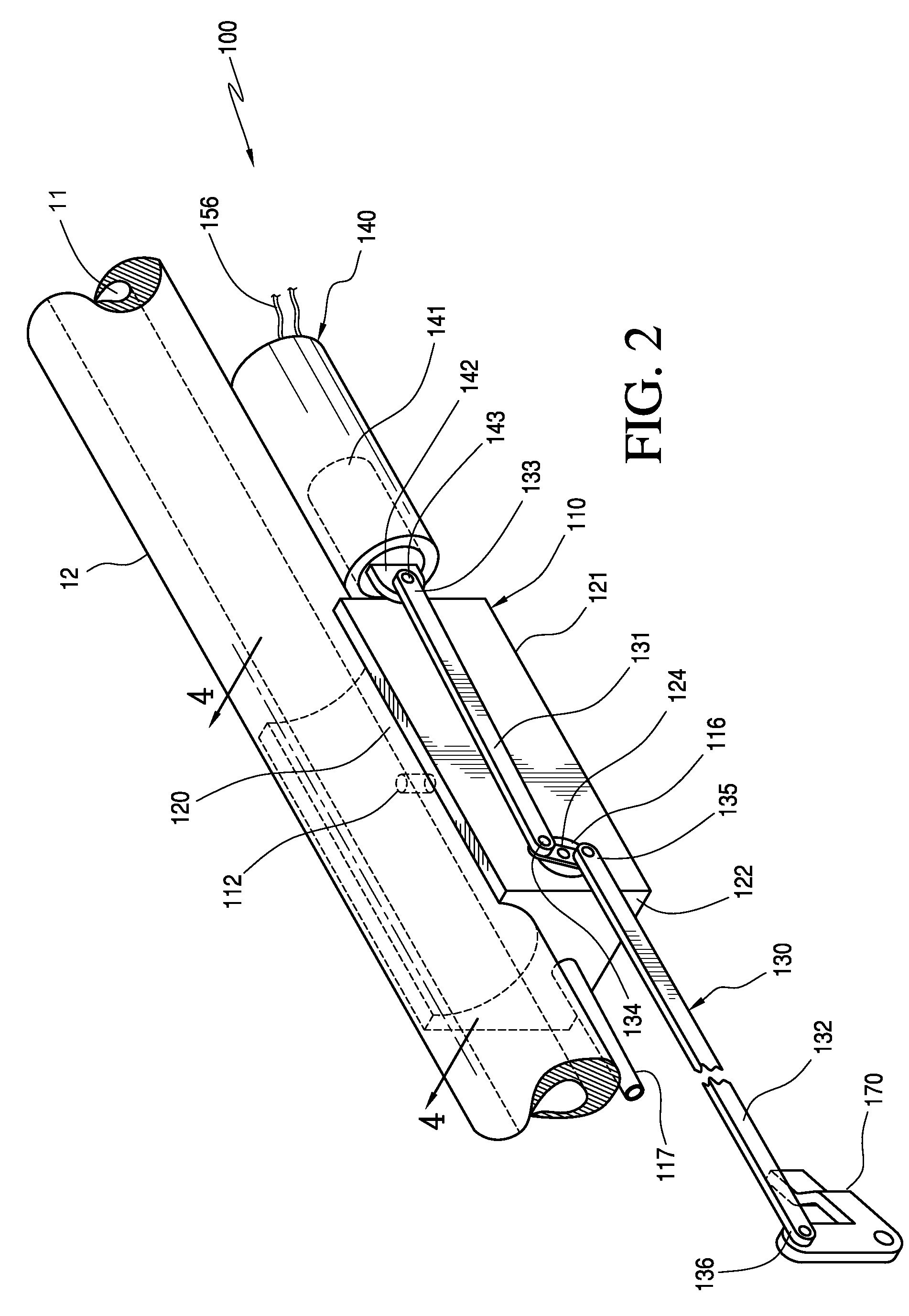

[0036]FIG. 1 is an exploded perspective view of a gas operated delay action rifle 10, made in accordance with the present invention. FIG. 2 is a detail view of action delay assembly 100 of the rifle 10, made in accordance with the present invention. FIG. 3 is a conventional gas operated action semi-automatic rifle 1 detailing common components. The conventional gas operated semi-automatic rifle 1 of FIG. 3 comprises items common to most semi-automatic rifles, such as a barrel 2, a receiver assembly 3, a fore-end assembly 4, and a stock 5. Other items common to conventional semi-automatic rifles are a breach bolt assembly 6, an action port tube 8 and an action spring 9 disposed within the receiver assembly 3. Further, the conventional rifle 1 in FIG. 1 includes a trigger assembly 7. When a shooter fires the conventional rifle 1 shown in FIG. 3, the rapidly expanding gases created by the ignition of gun powder in a cartridge pushes a bullet out of the barrel 2. The gases also are port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com