Vegetation trimmer having a blowing function

a technology of vegetation trimmer and air blowing function, which is applied in the field of vegetation trimmer also having a blowing function, can solve the problems of not being able to provide a string trimmer having both a step-down gear mechanism and a cutting device, and achieve the effect of maintaining the efficiency of the air blowing function, reducing the amount of air exiting the air outlet, and reducing the amount of air leaving the air outl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

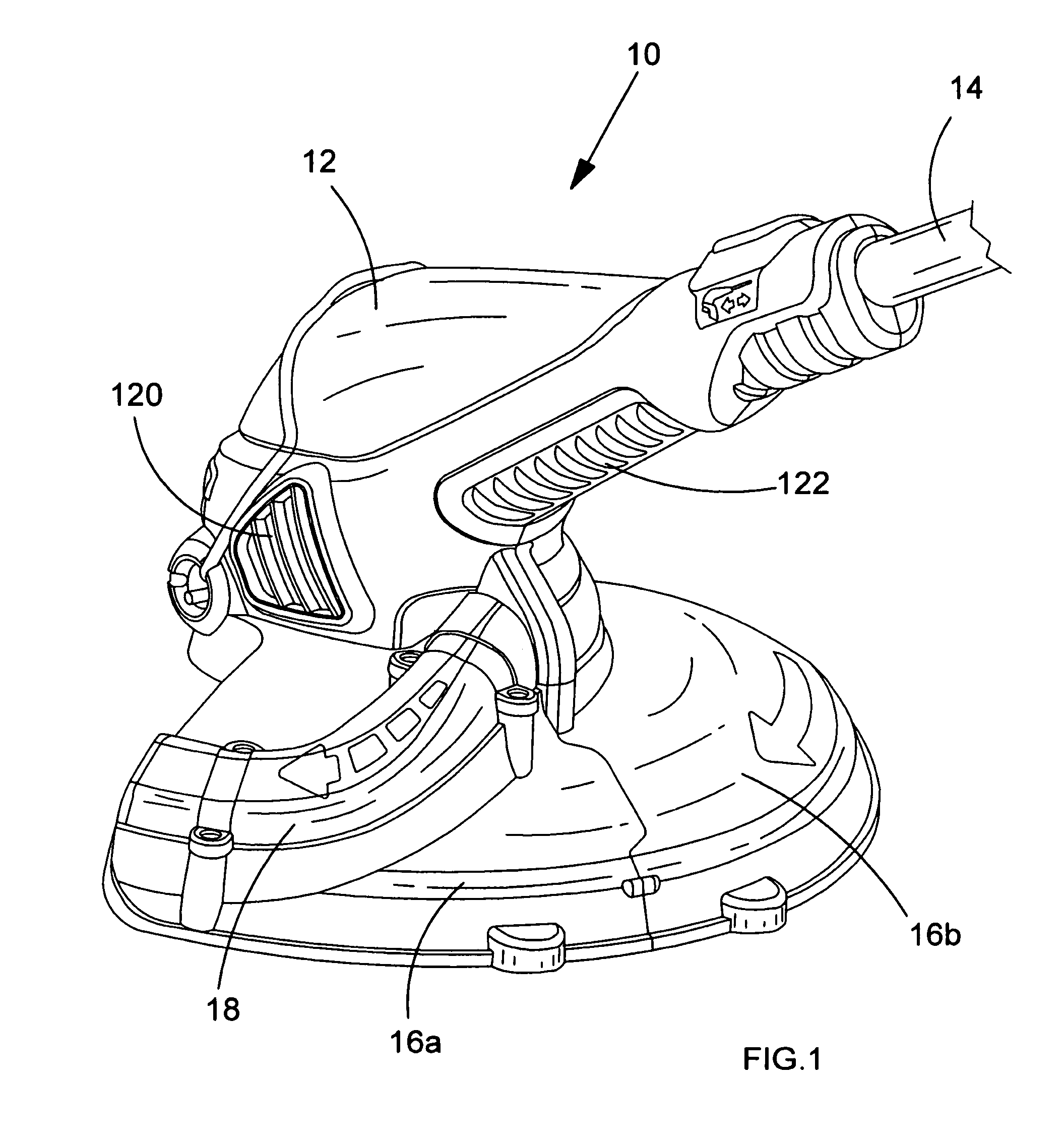

[0022]Referring firstly to FIG. 1, there is shown a lower end part of a vegetation trimmer 10, comprising a motor housing 12, a shaft 14 and a guard. The guard is formed from two component pieces 16a, 16b. Mounted on one of the component pieces 16a of the guard is a duct 18 for conveying air. The motor housing 12 additionally comprises air inlet vents 120 and outlet vents 122 for providing cooling air to a motor contained therein.

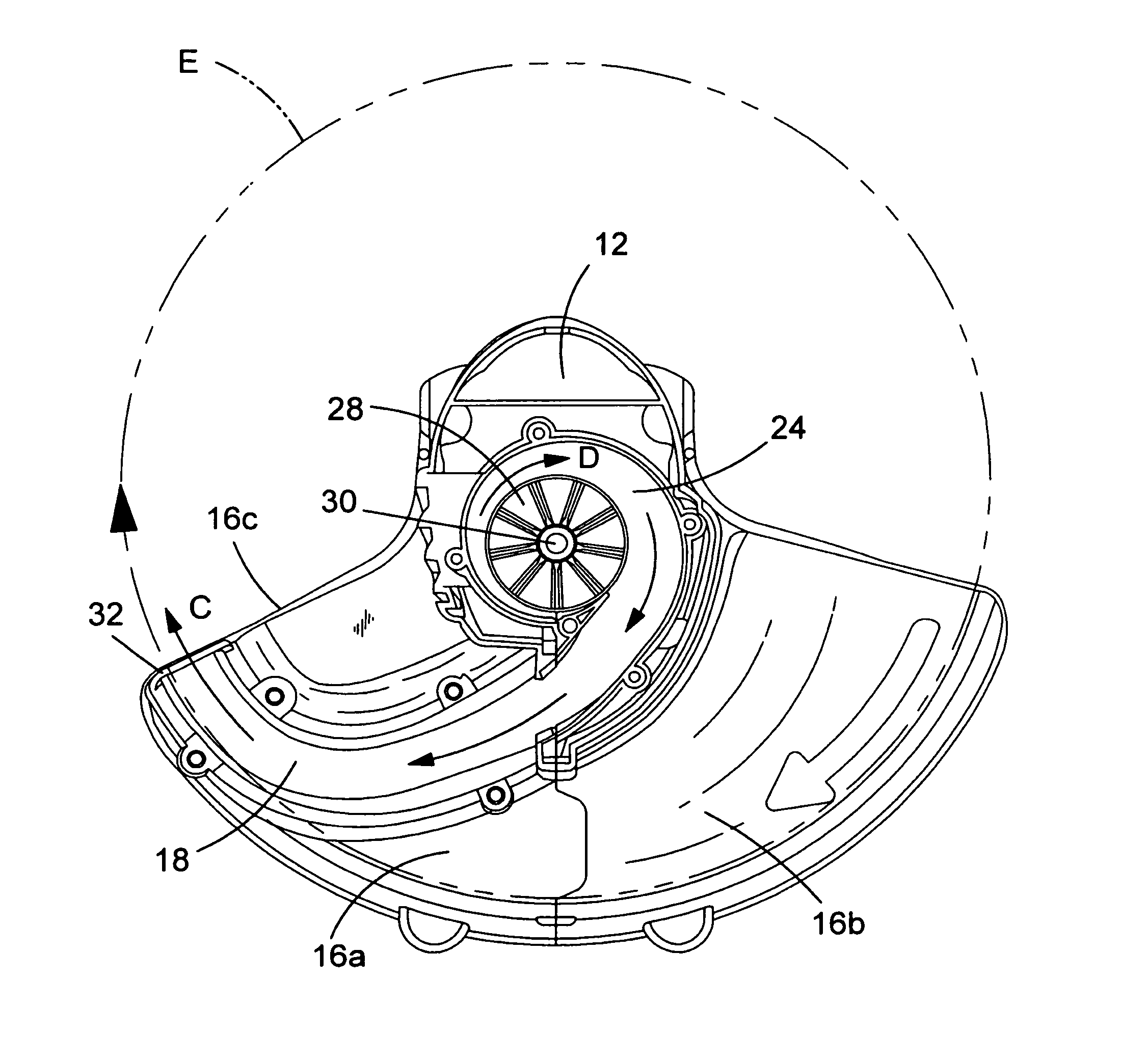

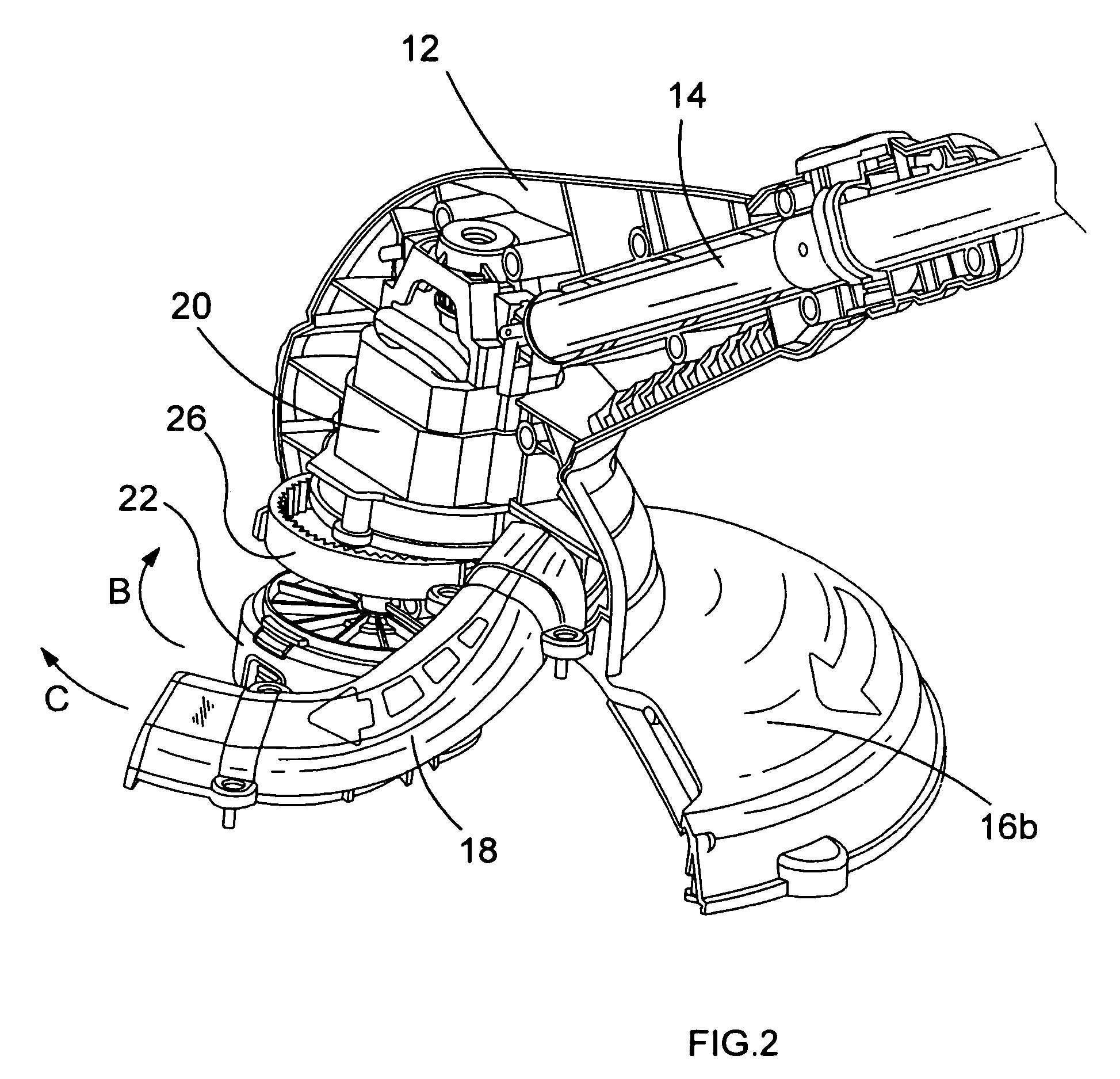

[0023]FIG. 2 is a partial cut-away view of the lower end part of the vegetation trimmer shown in FIG. 1. Within motor housing 12 there may be seen the motor 20. Electrical power for the motor is supplied thereto by electrical wires contained within shaft 14. When the motor is running, cutting head 22 is caused to rotate thereby in the direction indicated by arrow B. At the same time, air is expelled from duct 18 in the direction indicated by arrow C as a result of being blown by a fan contained within volute 24. As can be seen in FIG. 2, the drive train fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com