Information processing apparatus, and method for controlling image forming apparatus

a technology of information processing apparatus and image forming apparatus, which is applied in the field of gloss control, can solve the problem of not being able to sufficiently control and achieve the effect of suitably controlling the smoothness of the print medium surface depending on the accumulation of pigment ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0024]An image forming apparatus according to a first embodiment of the present invention will be described below taking an inkjet printing apparatus that performs multi-pass printing as an example.

[0025]Outline

[0026]The present inventors have found that the smoothness of the print medium surface changes when an image is formed using a pigment ink by changing the distribution of recording rate (thinning ratio) for each pass in multi-pass printing. Based on this finding, in the present embodiment, the smoothness depending on accumulation of the pigment ink in multi-pass printing is controlled by controlling the distribution of printing ratio for each pass in the multi-pass printing, whereby the smoothness can be controlled more suitably in multi-pass printing as compared to the technique disclosed in Patent Document 1 (in which the printing ratio among passes is constant).

[0027]Apparatus Configuration

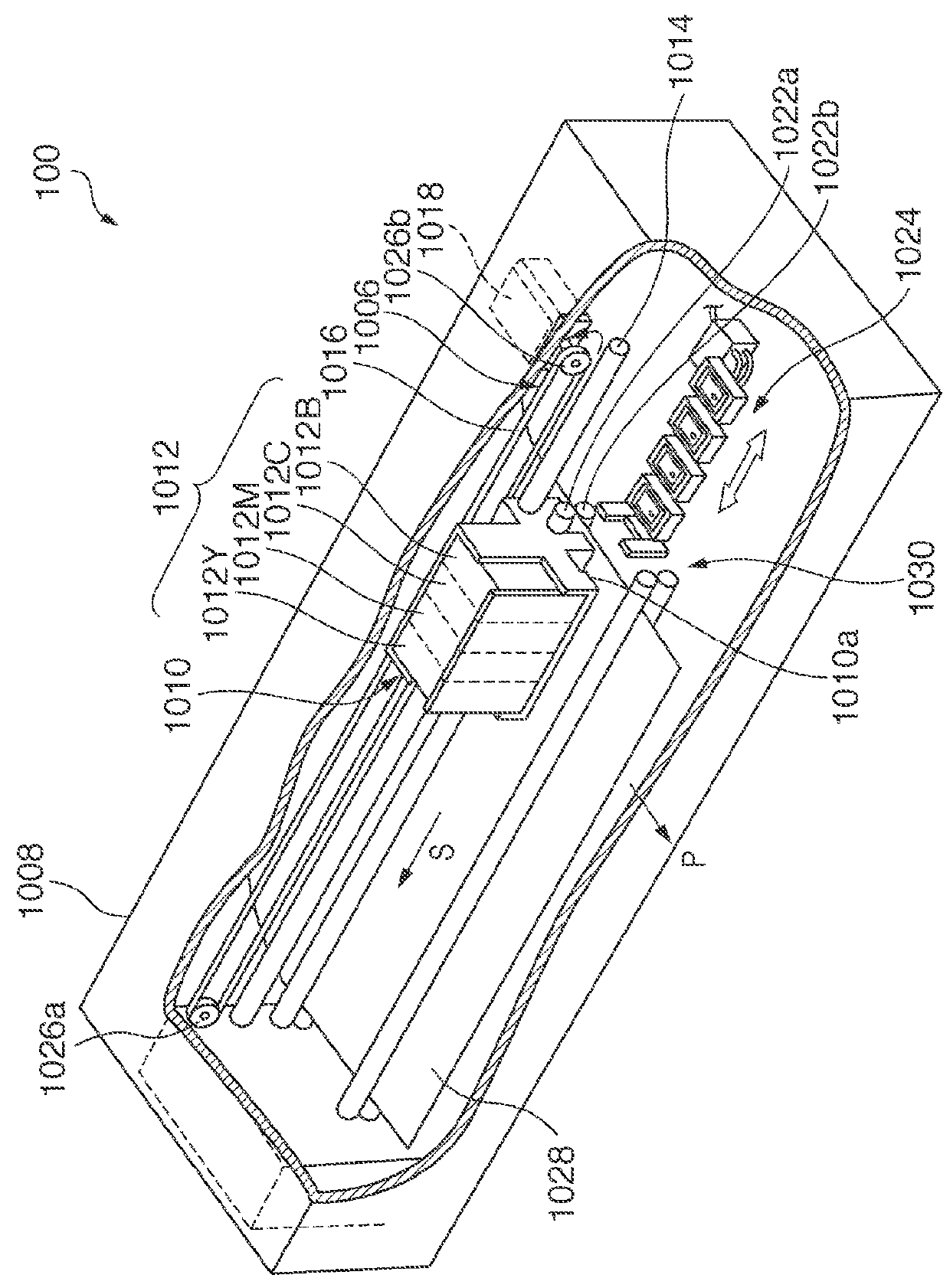

[0028]FIG. 1 is a schematic perspective view of an inkjet printing apparatus 100 acc...

second embodiment

Outline

[0070]According to a second embodiment, when a printing apparatus performs printing on glossy paper that is not supported by the standard driver, or when an influence resulting from individual differences in printing apparatuses, the environment or the like occurs, desired gloss properties can be obtained by selecting a more accurate and suitable printing method.

[0071]Apparatus Configuration

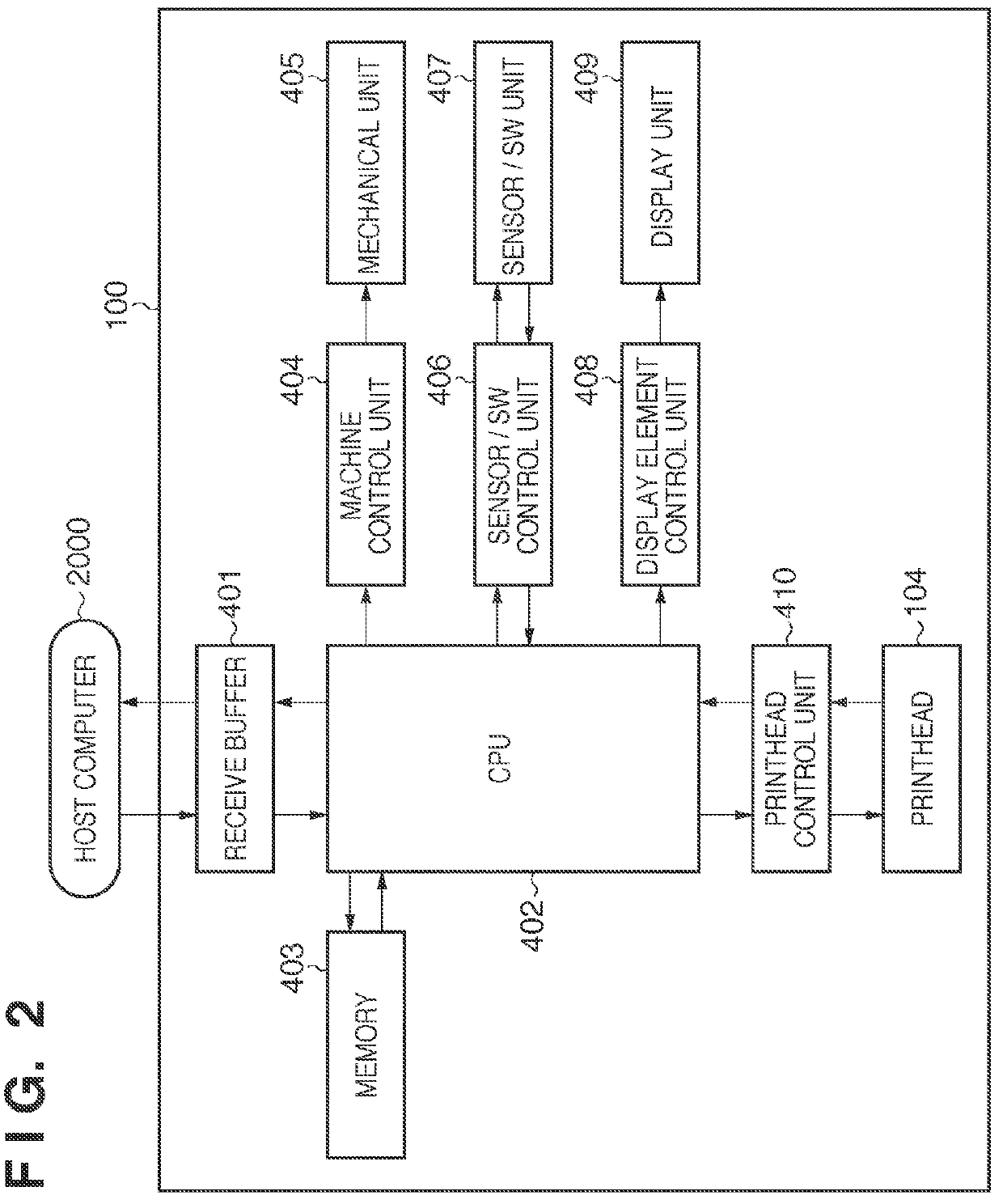

[0072]An inkjet printing apparatus 200 according to the second embodiment is obtained by adding a gloss sensor to the inkjet printing apparatus 100 (FIG. 2) of the first embodiment. The gloss sensor is included in the sensor / SW unit 407 shown in FIG. 2. The gloss sensor (gloss measuring unit) measures the gloss level of an image printed on a print medium and transfers information regarding the acquired gloss level to the CPU 402. Accordingly, it is suitable to attach the gloss sensor in the periphery of a paper discharge unit.

[0073]In the experiment conducted by the inventors, a photo-refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com