Actuator and vehicle lighting device

a technology for actuators and vehicles, applied in the field of circuit units, can solve the problems of circuit board likely to be bent, circuit board likely to be distorted, circuit board likely to be damaged, etc., to suppress the manufacturing cost and environmental impact, reduce the amount of solder, and improve the appearance of the soldered part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

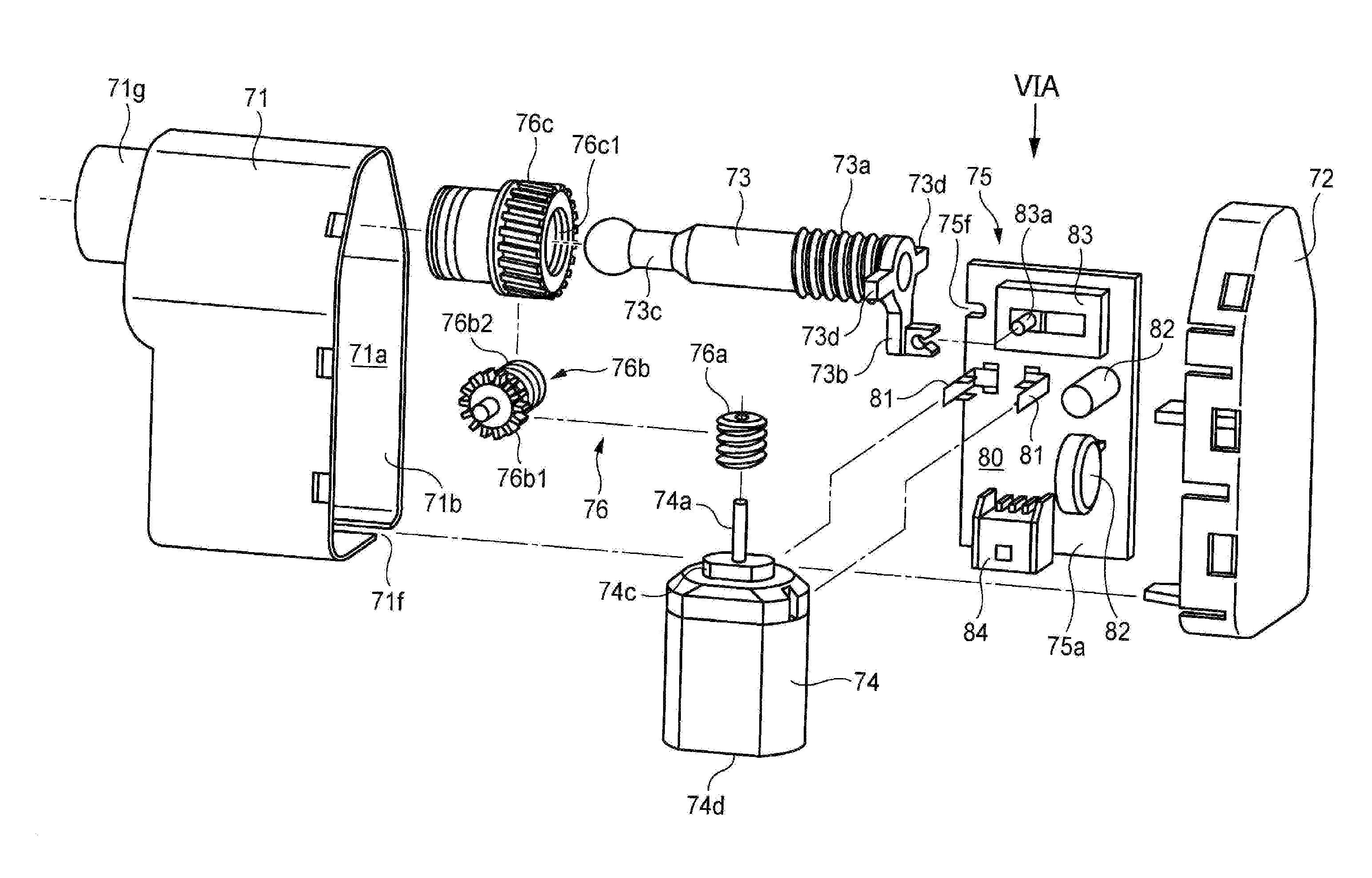

Embodiment Construction

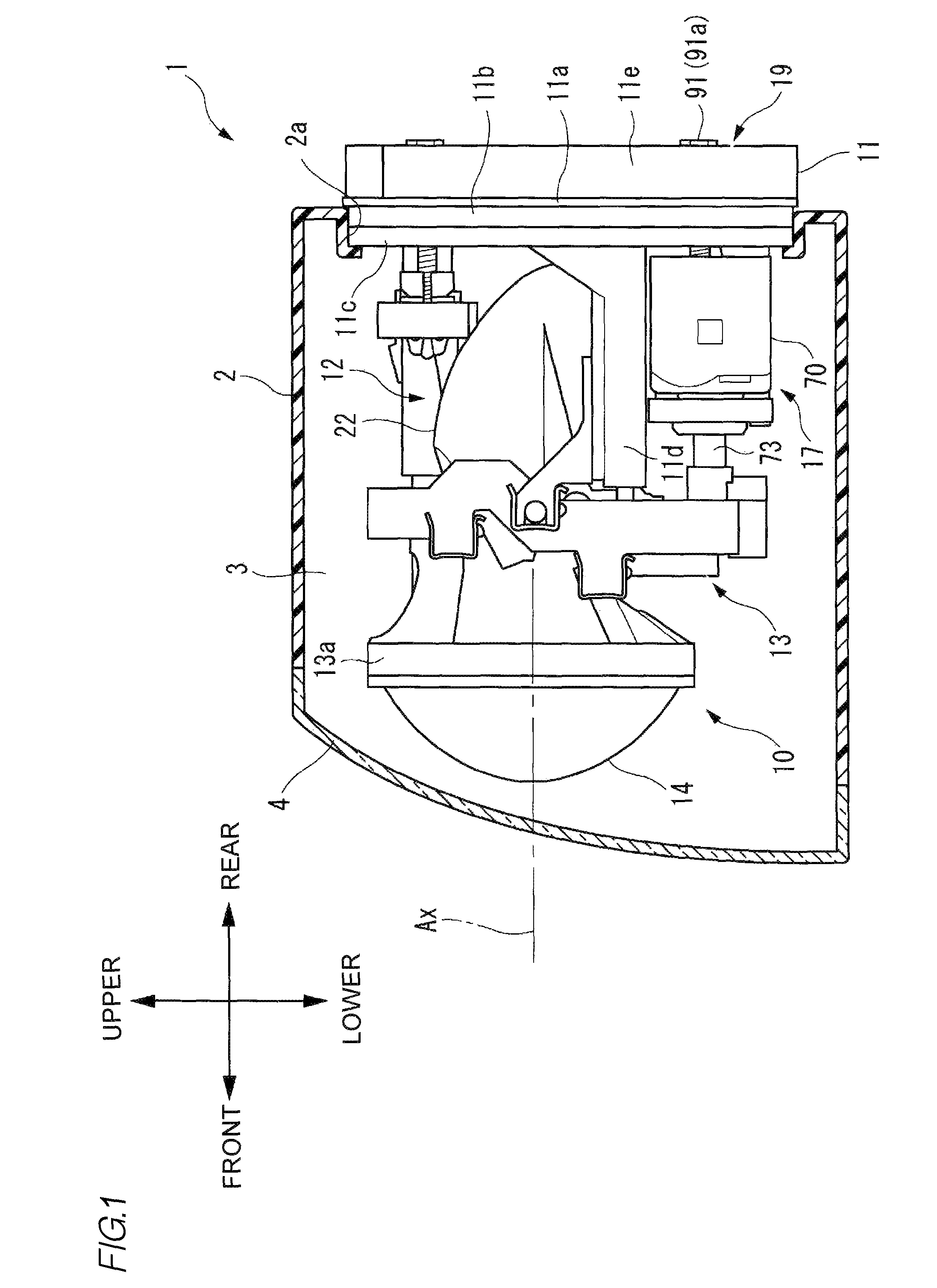

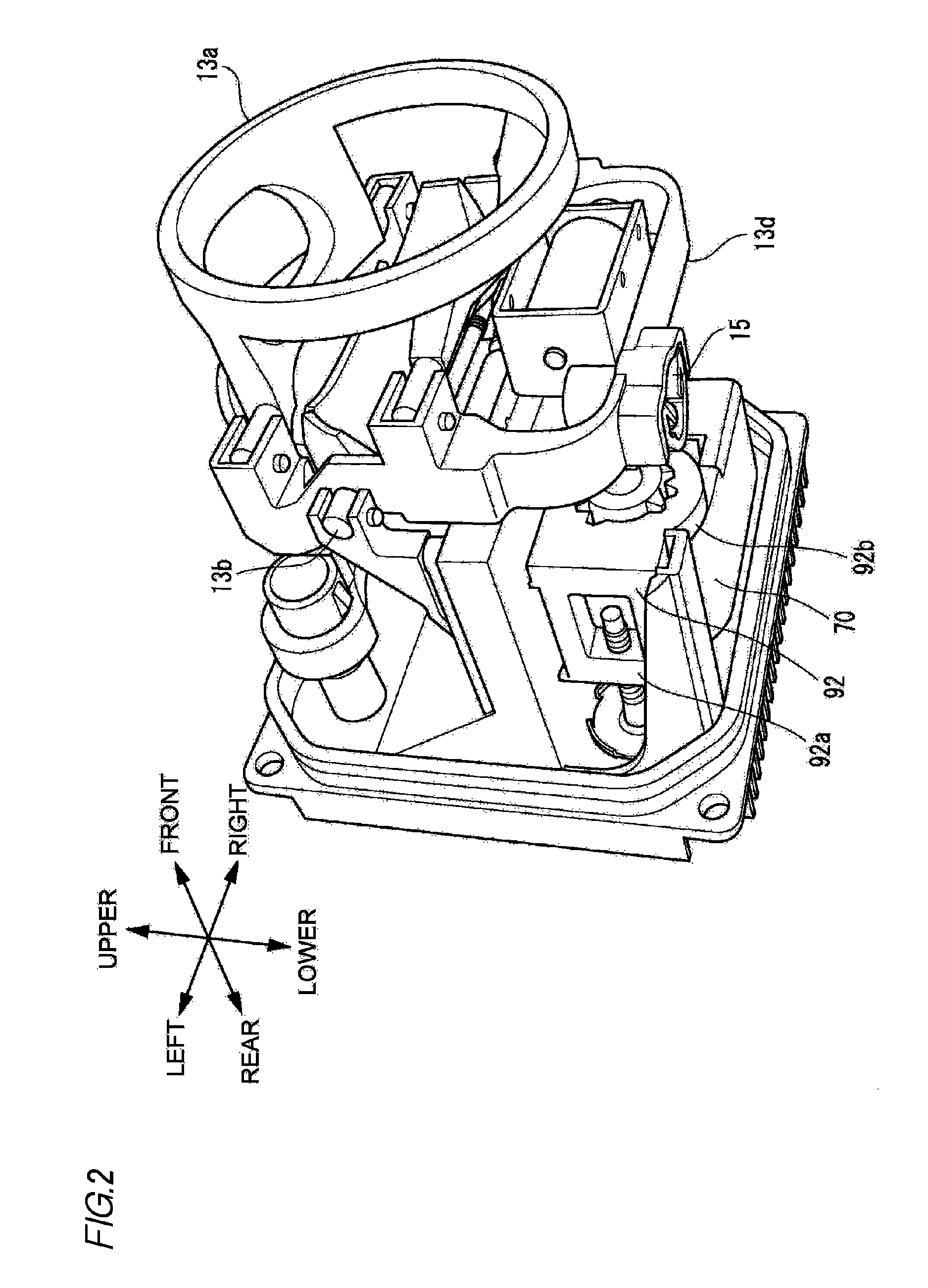

[0111]An illustrative embodiment of the present invention will be described in detail with reference to the accompanying drawings. Meanwhile, in the respective drawings used in the below descriptions, a scale is appropriately changed so as to show each member as a recognizable size.

[0112]FIG. 1 illustrates a part of a headlight device 1, which is an example of the lighting device according to an illustrative embodiment of the present invention, as seen from a vertically sectioned left side. The headlight device 1 is a device mounted at a front part of a vehicle and configured to illuminate the front of the vehicle. The headlight device 1 has a housing 2, and a translucent cover 4 mounted to the housing 2 and configured to define a lamp chamber 3. In the lamp chamber 3, a lamp unit 10 is arranged.

[0113]The lamp unit 10 has a heat sink 11, a light source unit 12, a lens holder 13, a projection lens 14, an actuator 17 and an aiming mechanism 19.

[0114]The heat sink 11 has a back plate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com