Compact two probe impedance tuner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

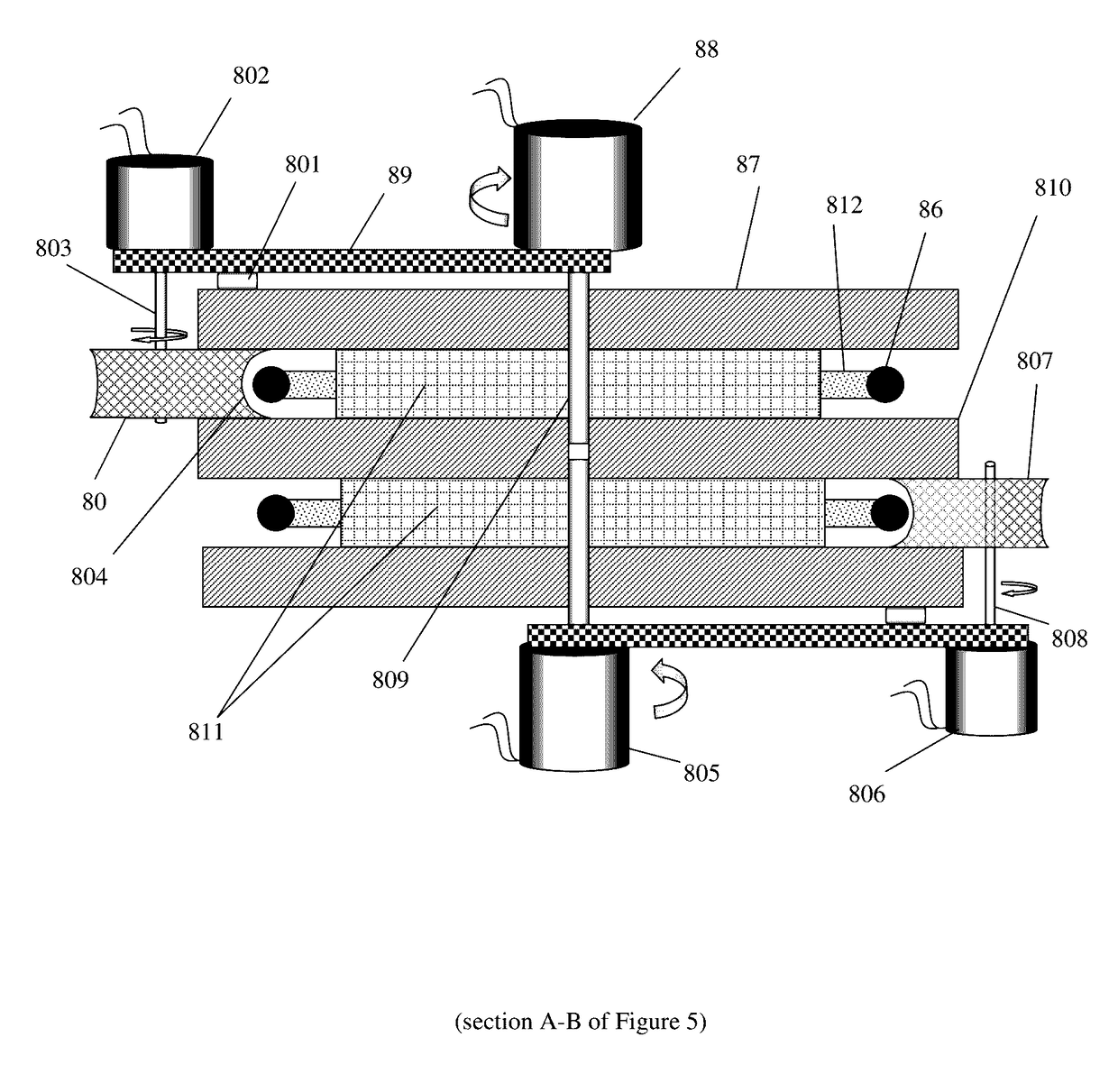

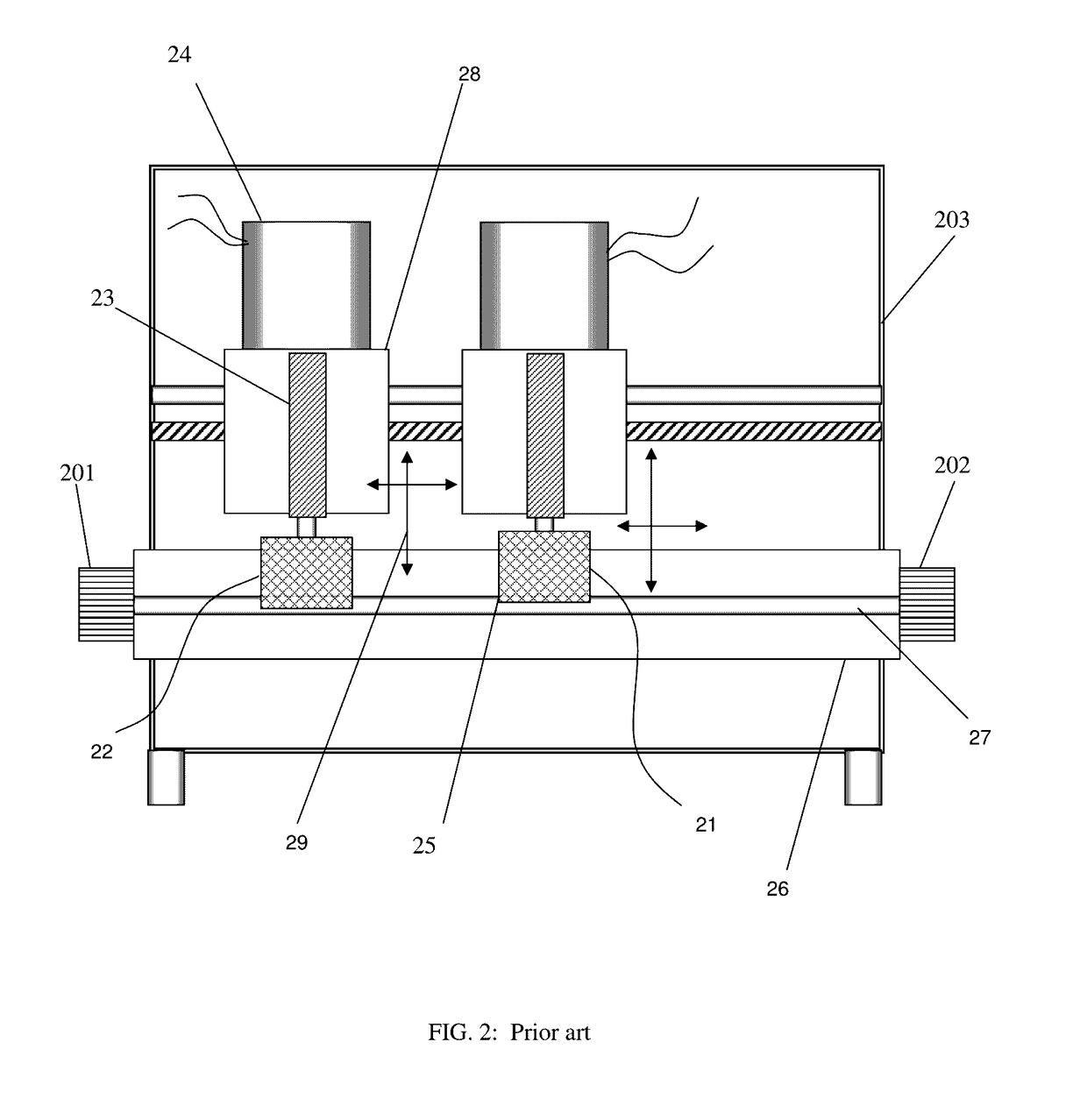

[0028]This invention discloses a new low footprint slide screw impedance tuner comprising two independent tuning probes, the compact two-probe circular tuner. The essential components of this new structure are:[0029]a. A double-decker (sandwich) set of circular horizontal slablines with circular (toroid) center conductors.[0030]b. Two independently driven eccentrically rotating disc-(tuning) probes.[0031]c. Two mobile carriages in form of independently driven and rotating radial arms.[0032]d. Stepper motors, electronic control and mechanical control gear.

[0033]The effect of using the new structure is reducing the overall horizontal length (footprint) of a prior art (linear) two-probe tuner by a factor, which depends on the minimum frequency of operation, and ranges between 9.5 (at Fmin=100 MHz) and 4.2 (at Fmin=800 MHz); (compare FIGS. 2 and 8 and see ref. 2); table I summarizes this:

[0034]

TABLE IComparison of total length of prior art linear and new circular two-probe tunersMinimum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com