Single-cam compound archery bow

a compound archery bow and single-cam technology, applied in the field of single-cam compound archery bows, can solve the problems of affecting the accuracy of the bow, not disclosing any means or techniques for adjusting the draw length of the bow, and less than the optimal performance of the bow, so as to reduce twisting forces, reduce lateral separation, and facilitate the effect of manufacturing and servi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

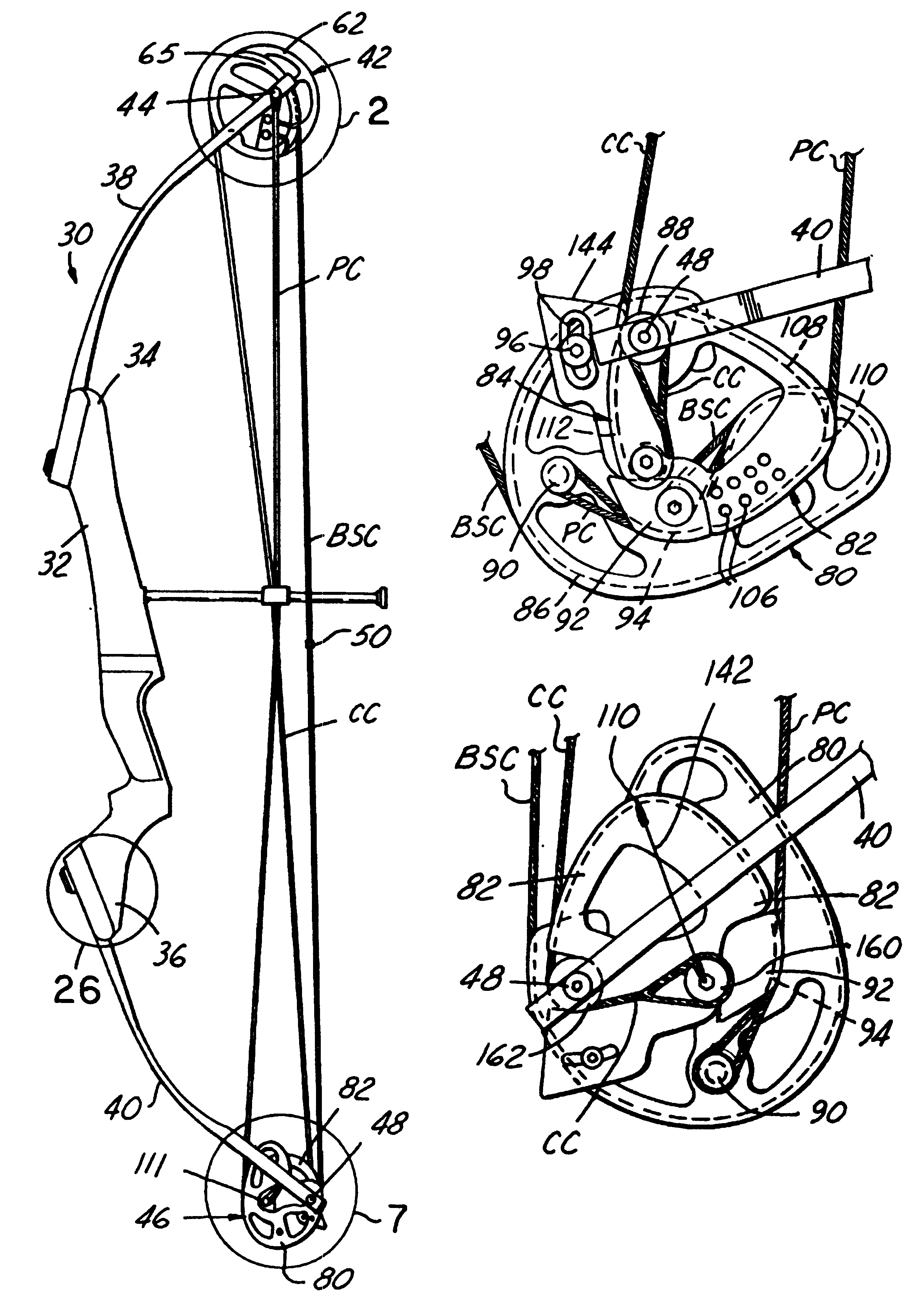

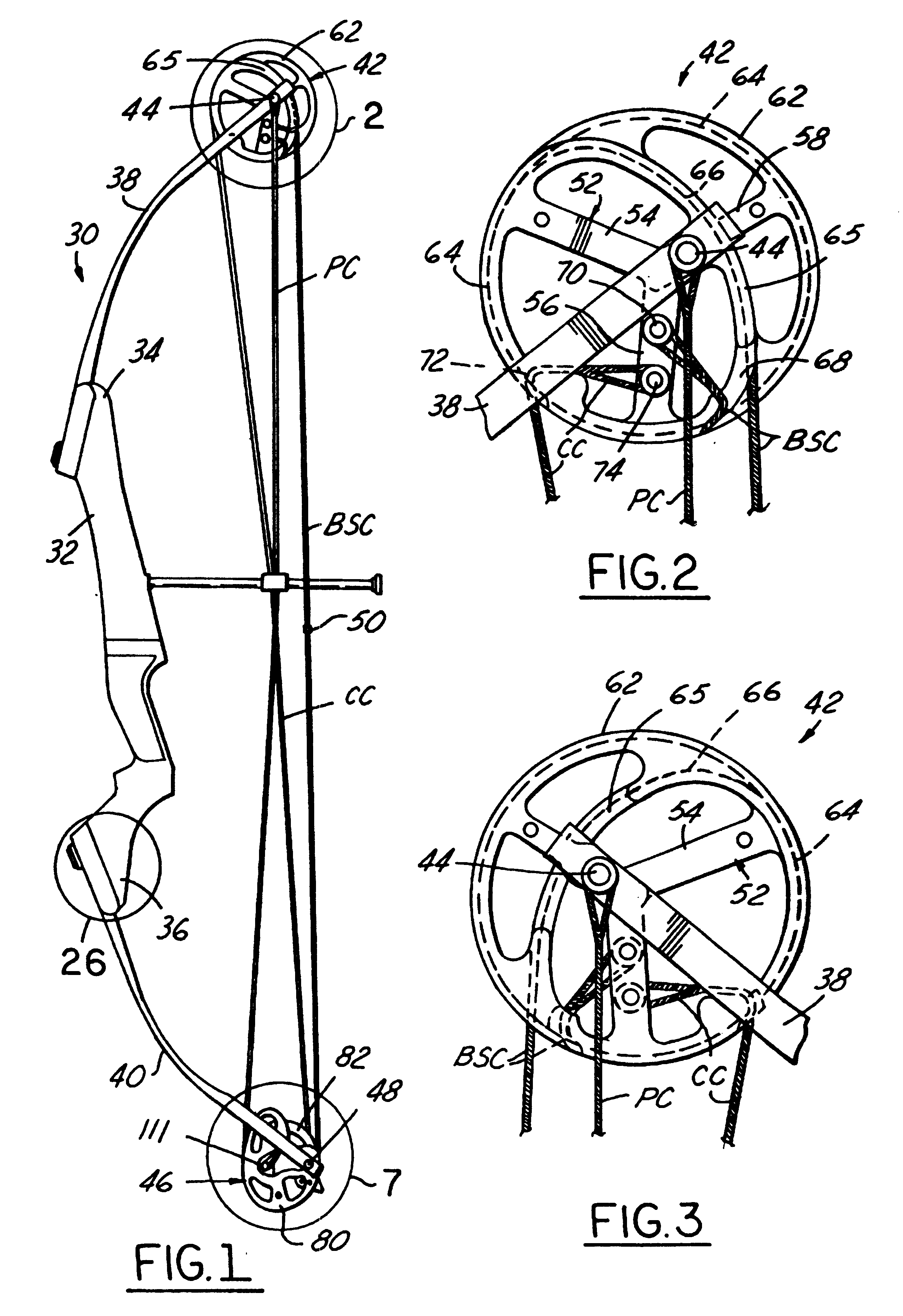

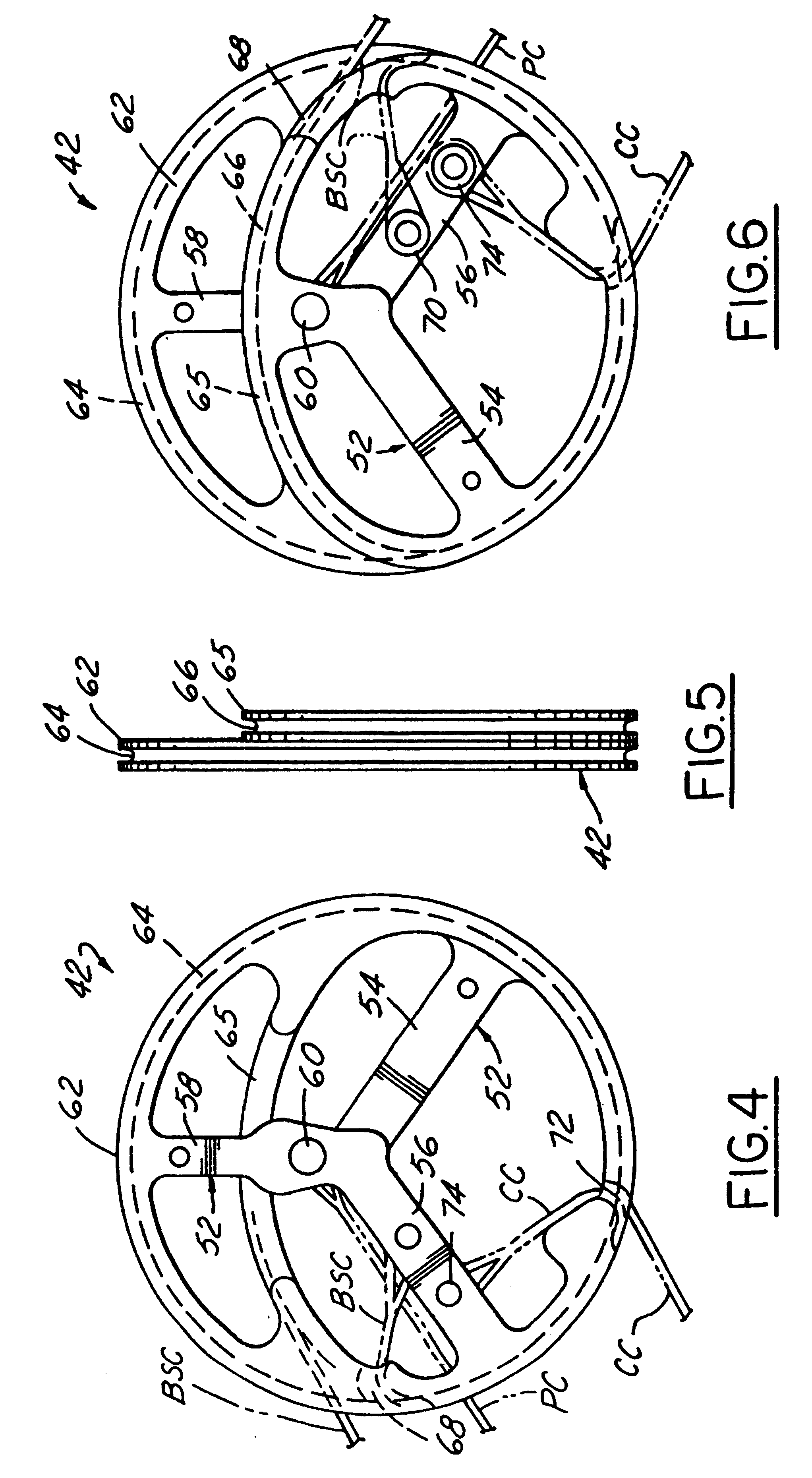

FIG. 1 illustrates a single-cam compound archery bow 30 in accordance with a presently preferred embodiment of the invention as comprising a handle 32 of cast magnesium or other rigid unitary construction having spaced ends 34, 36 with flat limb-mounting surfaces at each end. A pair of flexible limbs 38, 40 of fiber-reinforced resin or other suitable resilient construction are mounted on handle ends 34, 36 respectively, and project therefrom away from handle 32. A control wheel 42 is rotatably mounted on an axle 44 that extends laterally across the free end of bow limb 38, such that control wheel 42 is rotatably mounted within an open notch at the free end of limb 38. Likewise, a power cam 46 is rotatably mounted on an axle 48 that extends laterally across the free end of limb 40, such that power cam 46 is rotatably mounted within a notch 50 (FIG. 9) at the free end of limb 40. A power cable PC has a split end that is anchored to limb 38 at axle 44, preferably although not necessari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com