Molded plastic ramp

a molded plastic and ramp technology, applied in the direction of amusements, skiing, construction, etc., can solve the problems of insufficient side and rear reinforcements of freeberg, insufficient side reinforcements, and insufficient side reinforcements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

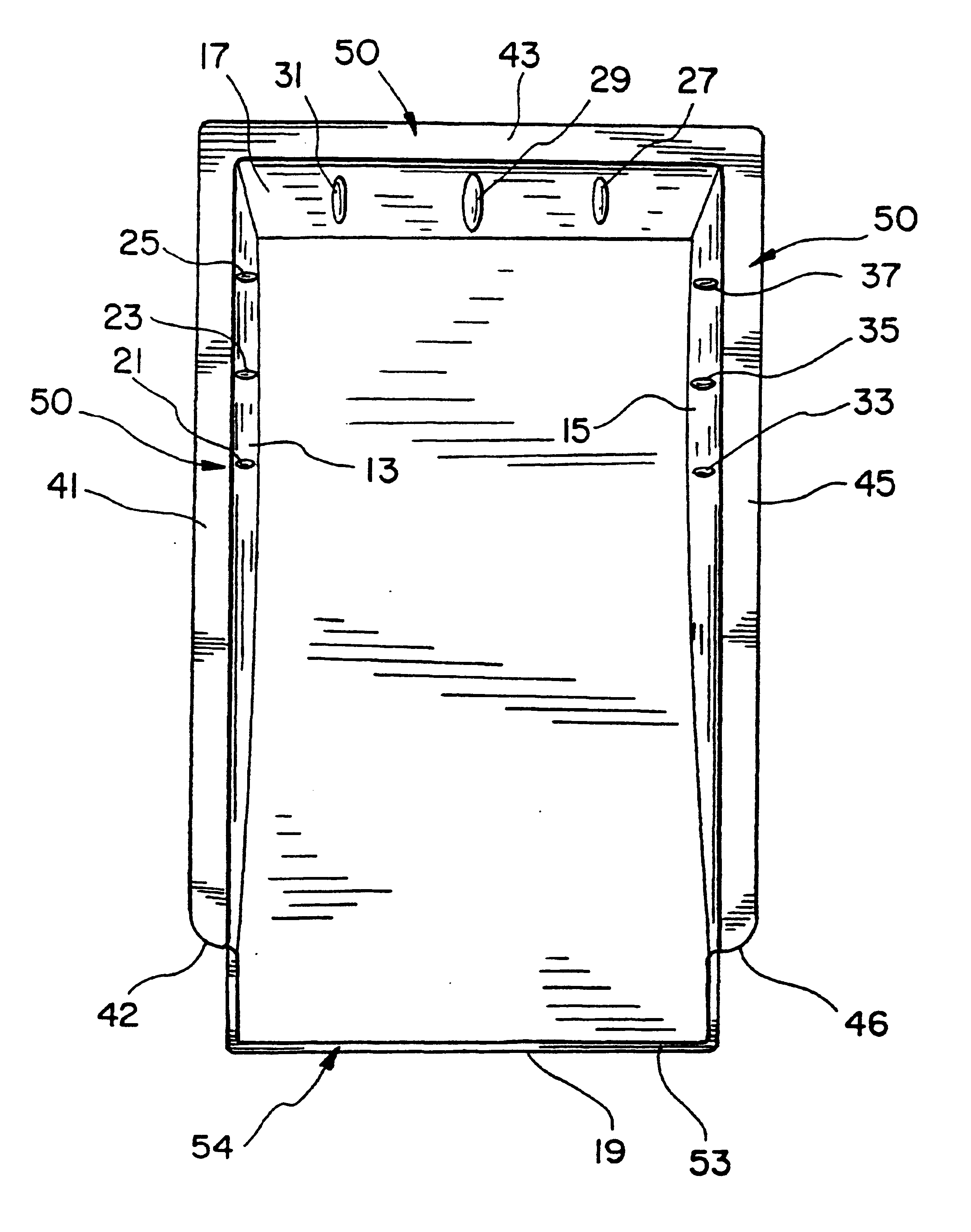

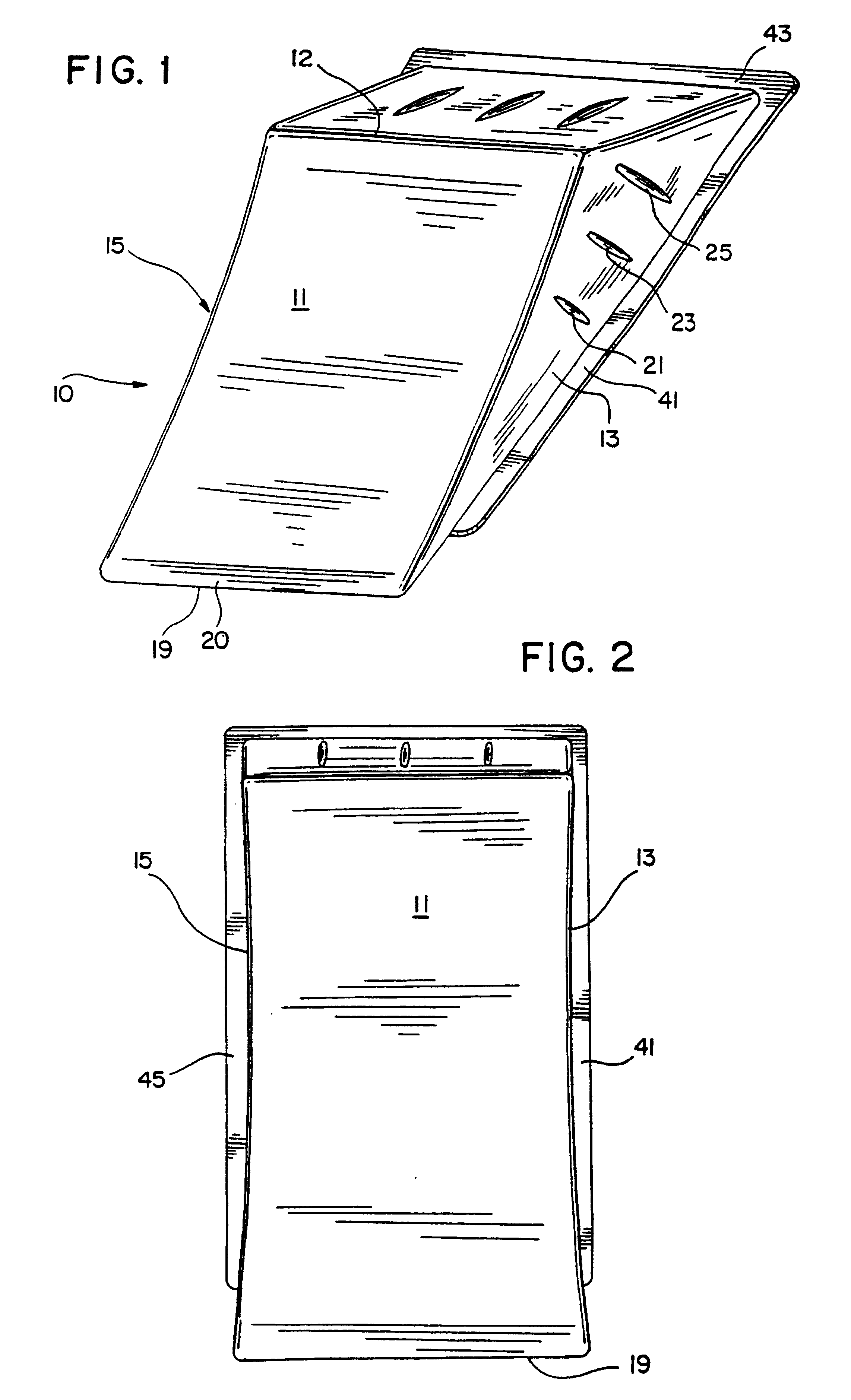

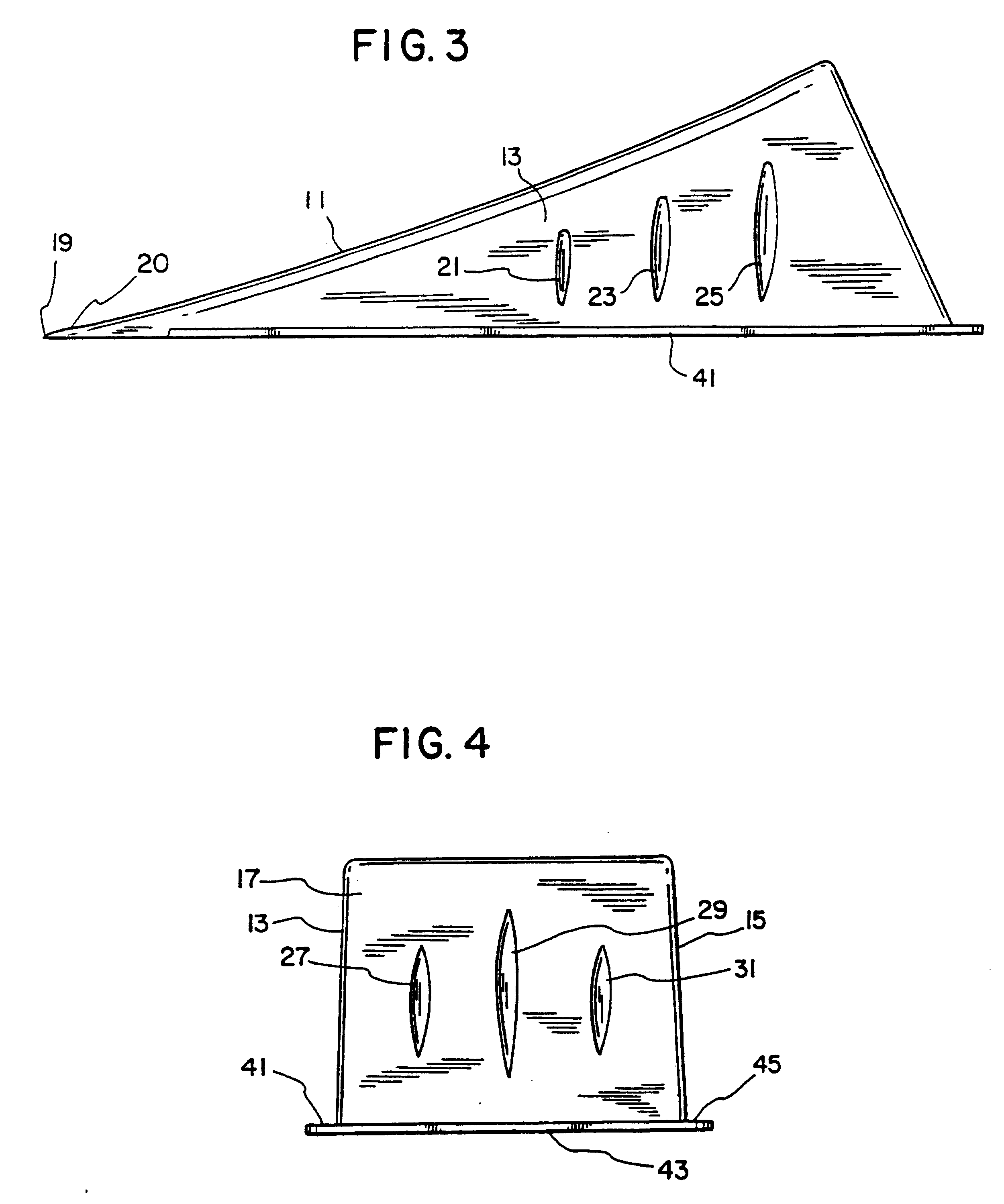

The present invention is generally designated by the reference numeral 10 and is seen to include a smooth radiused ramp surface 11, side walls 13 and 15, and a rear wall 17. The ramp surface 11 includes a forward edge 19 that extends down to the bottom-most extent of the device 10 so that when the device 10 is placed on a flat ground surface, the edge 19 is substantially flush with the ground surface so that users have a smooth transition from the ground surface to the ramp surface 11 especially where small-wheeled vehicles such as skateboards and inline skates are used. The ramp surface preferably extends in a substantially uniform width from the forward edge 19 to the rear edge 12.

As seen in the figures, each of the side walls 13, 15 and the rear wall 17 are integrally reinforced. Thus, the side wall 13 includes depressions 21, 23 and 25 that comprise reinforcing ribs strengthening the side wall 13. These depressions are best seen in FIGS. 1 and 3. With reference to FIG. 5, these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com