Golf club

a technology of golf club and ball, which is applied in the field of golf clubs, can solve the problems of unrecoverable energy put into the hands from twisting the club, unsuitable for golf clubs, and inability to transfer the energy to the ball with conventional clubs, so as to improve the performance of the club and minimize the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

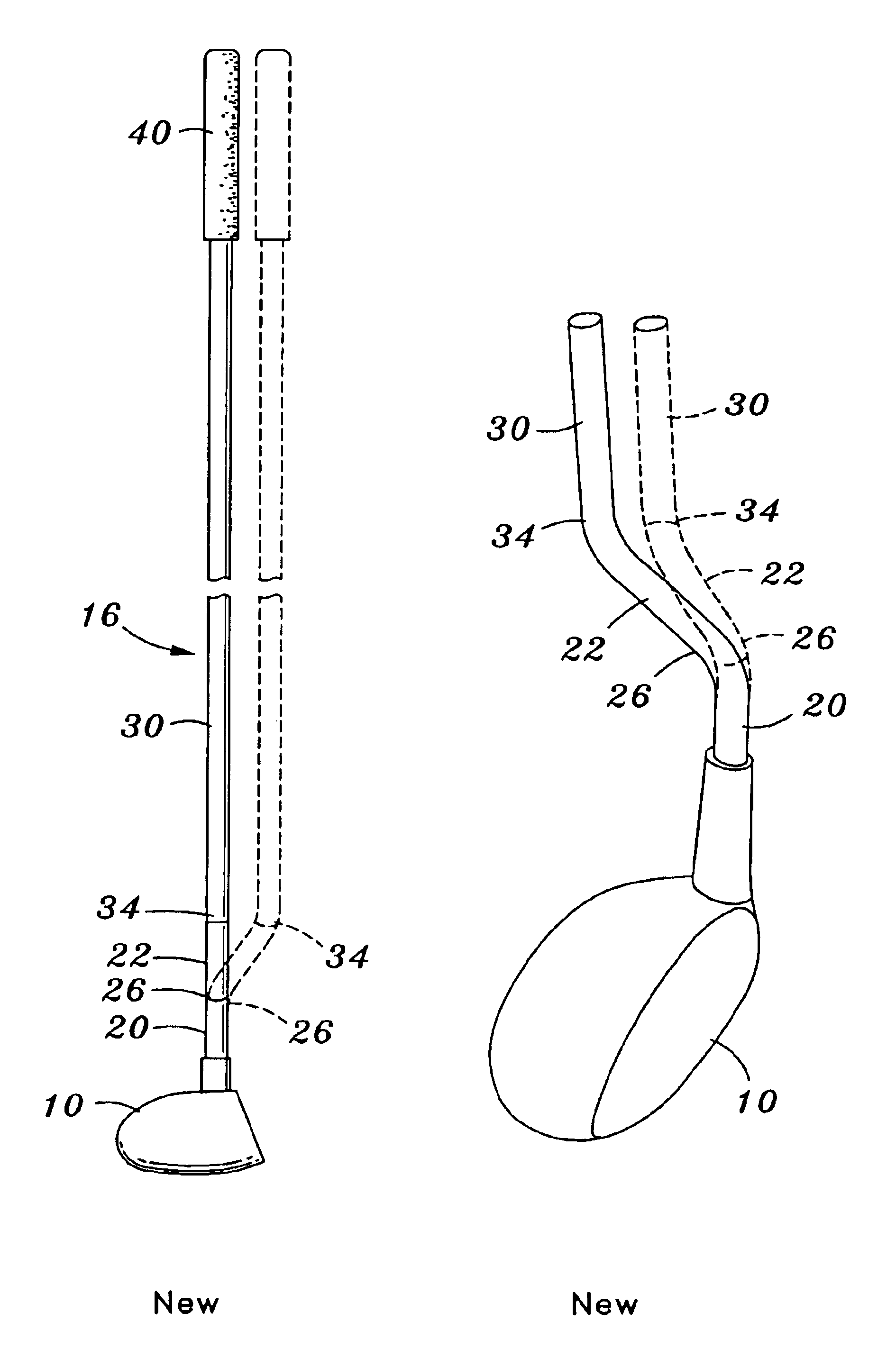

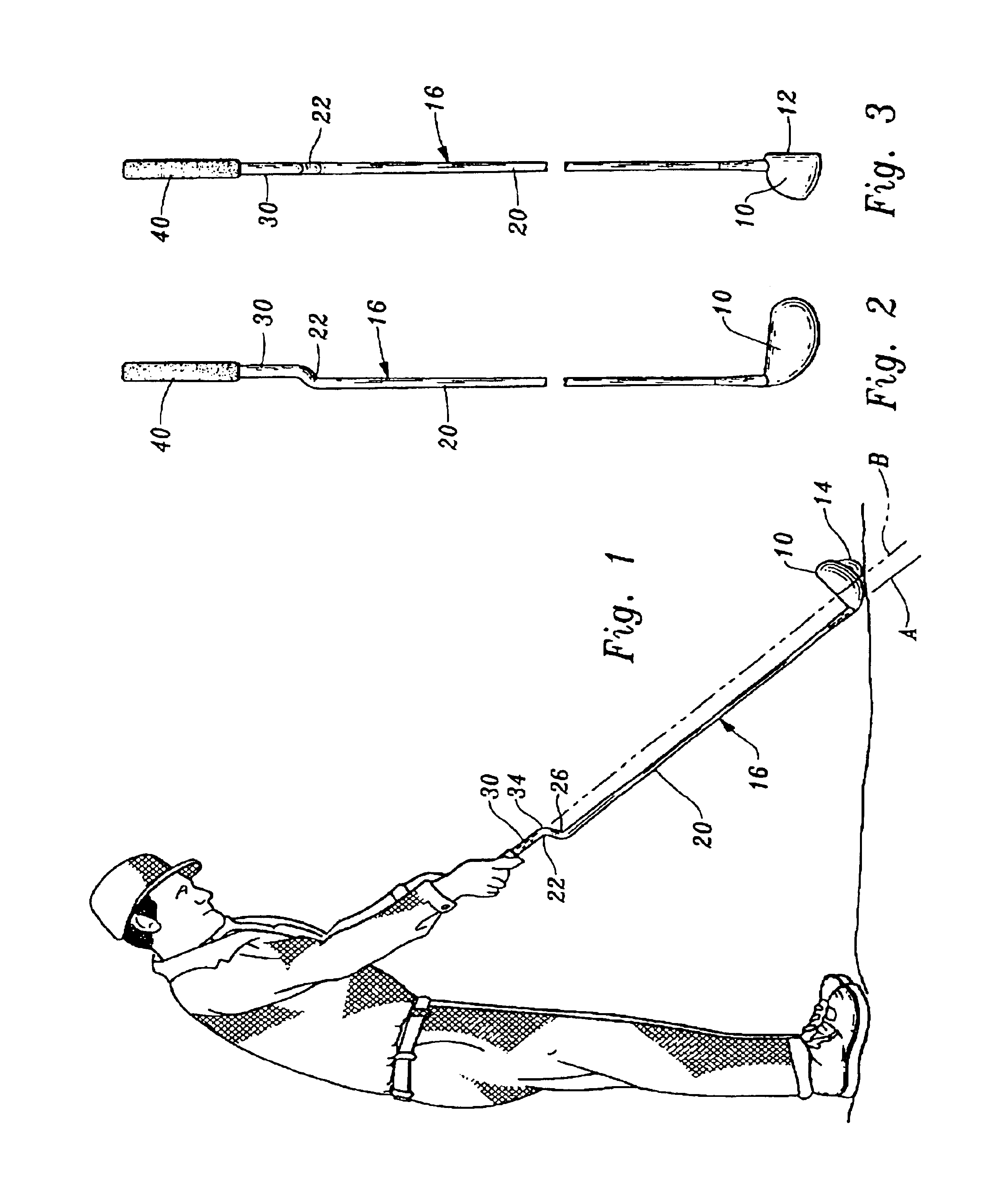

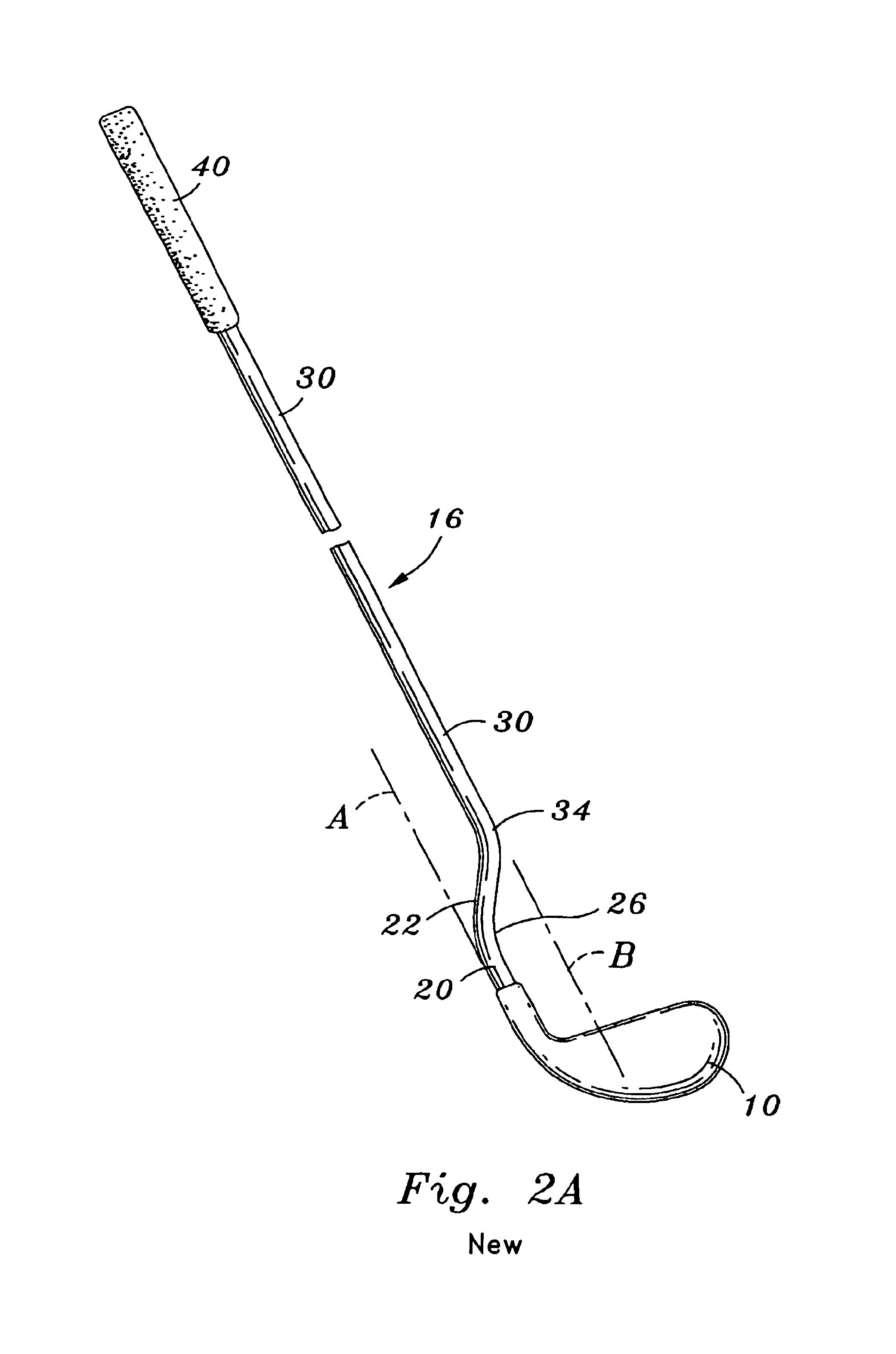

Referring now to FIGS. 1-6, a golf club constructed in accordance with the teachings of the present invention includes a club head 10 having a substantially planar golf ball engaging surface 12 (FIG. 3). In FIG. 1 a player is shown holding the club and addressing a golf ball 14.

A club shaft 16 is attached to the club head and extends upwardly therefrom. Club shaft 16 includes a straight first club shaft segment 20 extending upwardly from the club head along a first imaginary line A.

A straight second club shaft segment 22 adjoins and is integrally connected to the first club shaft segment at a lower bend 26. The second club shaft segment extends upwardly from and laterally relative to the first club shaft segment from the lower bend and defines an angle of divergence Y (See FIG. 35) with the first club shaft segment at the lower bend.

A straight third club shaft segment 30 adjoins and is connected to the second club shaft segment at an upper bend 34 spaced from the first club shaft se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com