Endodontic treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

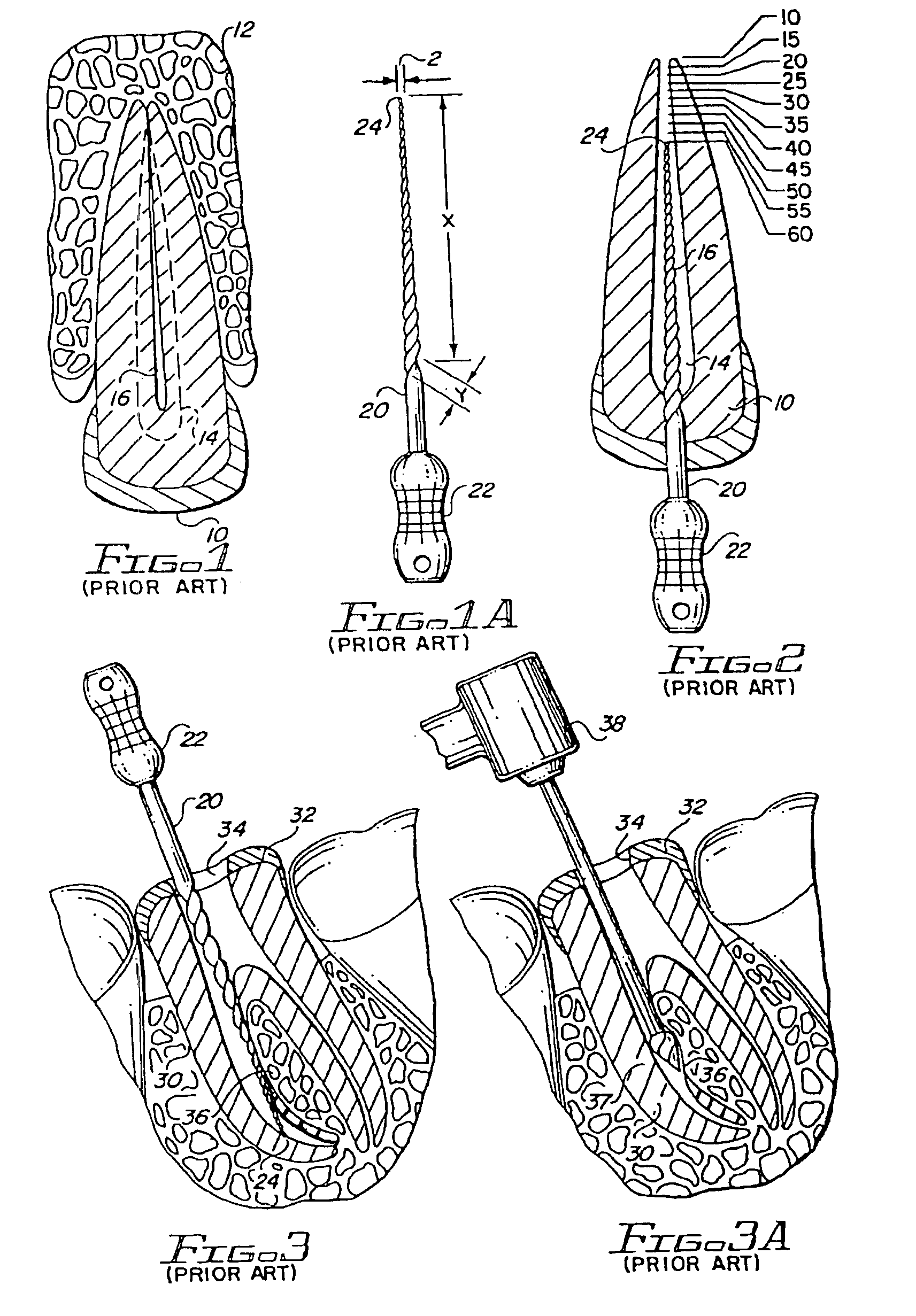

[0091]Before describing the present invention, it may be helpful to discuss briefly the root canal procedure as shown in FIGS. 1-3. FIG. 1 shows a tooth 10 located in the bore 12 of a jaw. The tooth 10 in FIG. 1 is an incisor, and the opening in the crown of the tooth 10 is cut on the side of the tooth 10 in the interior side of the jaw (not shown), which opening is generally indicated at 14. The tooth 10 has a nerve canal 16 extending to the tip of the tooth 10 which is embedded in the bone 12.

[0092]Also shown in FIG. 1A is a K-type file 20, having a handle 22 supporting the file 20. The file 20 has a flute length X, a shank diameter Y, and a tip diameter Z. In a standard file of this type, X=16 mm, Y=0.32 mm and Z varies with the size of the file, beginning with 0.06 mm for the smallest file and increasing to 1.4 mm for the largest files. The file 20 has a sharp tip 24, which is needed since each successive file in a series has a larger diameter at the tip. It should be noted that...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap