Mobile x-ray inspection system for large objects

a mobile x-ray inspection and large object technology, applied in the direction of material analysis, material analysis using wave/particle radiation, instruments, etc., can solve the problems of invading privacy, disruption (and in some cases damage) of property, and the penetration power of these sources is limited, and the inspection is limited to relatively small parcels and containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

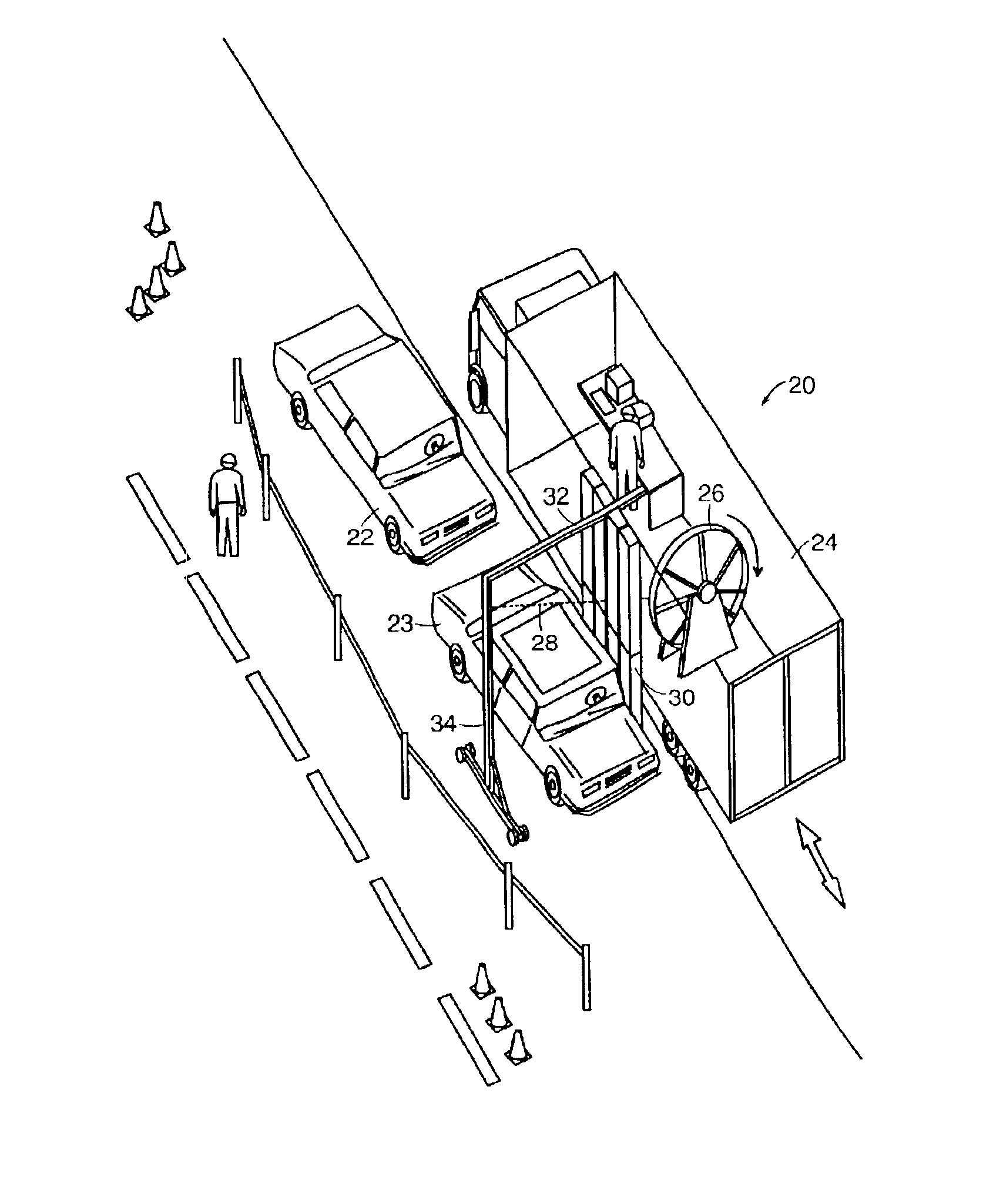

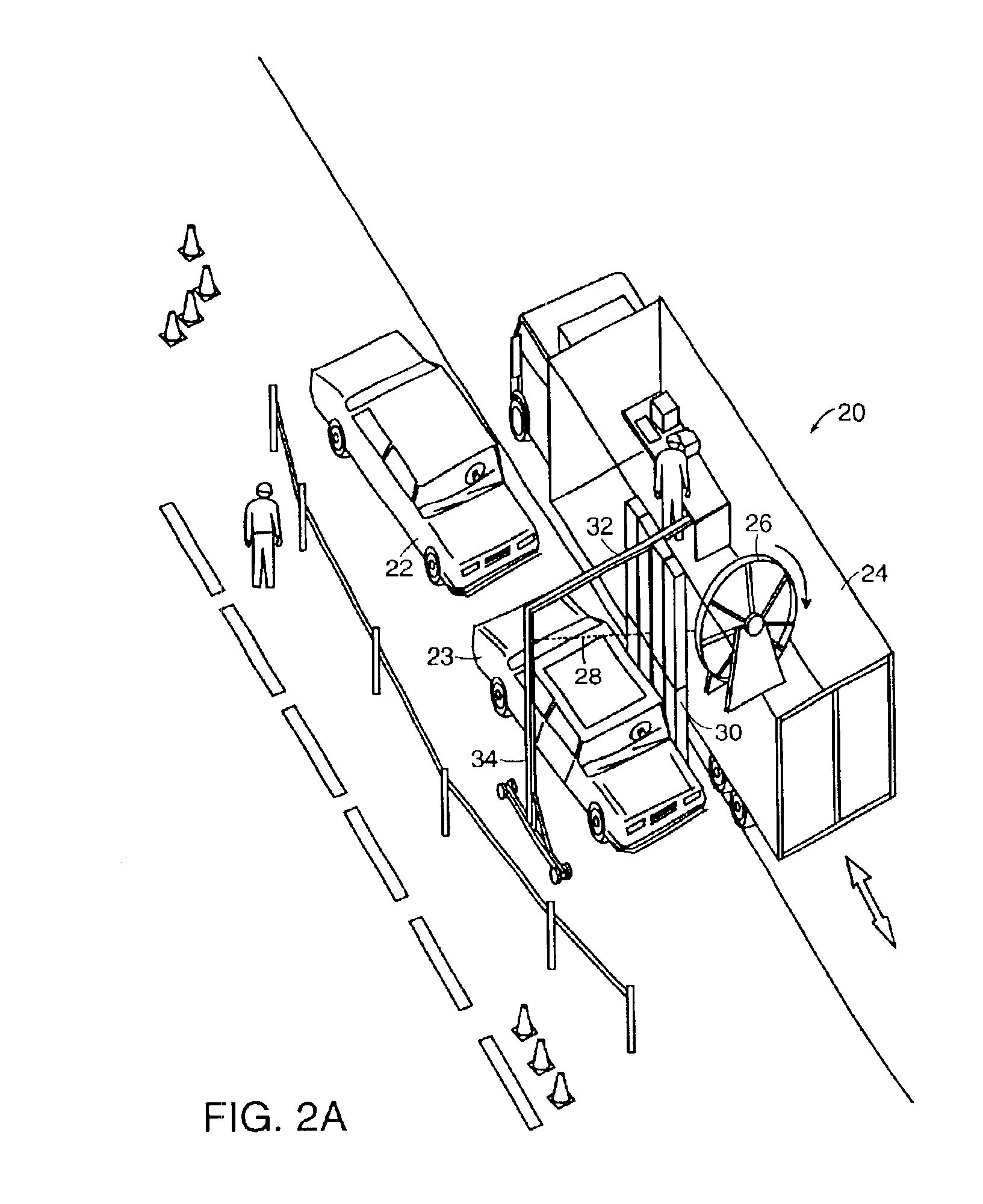

[0022]As used in this description and in the appended claims, a “cargo container” is a receptacle for the storage or transportation of goods, and includes freight pallets as well as vehicles, whether motorized or drawn, such as automobiles, the cab and trailer of a truck, railroad cars or ship-borne containers. The term “cargo container,” as used herein, further includes the structures and components of the receptacle.

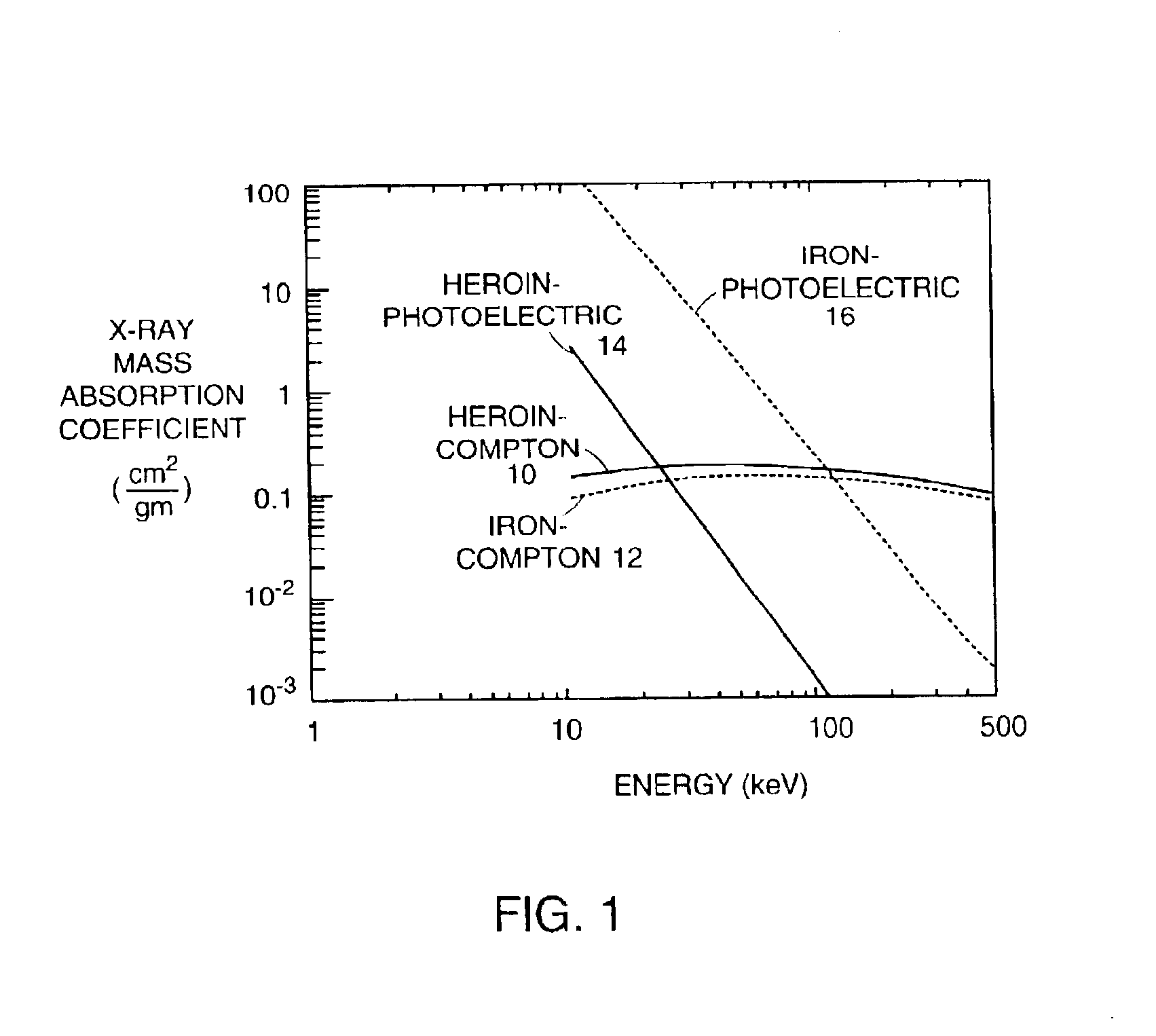

[0023]The invention described herein serves to characterize materials which may be contained within a cargo container and thus not readily susceptible to visual scrutiny. The characteristics of a material which might be the object of non-invasive inspection and which lend themselves to detection using the device and method taught by the invention include, but are not limited to, electron density, atomic number, mass density, linear dimensions and shape. These characteristics are unveiled by taking advantage of the various physical processes by which penetrating radiati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com