Waste bin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

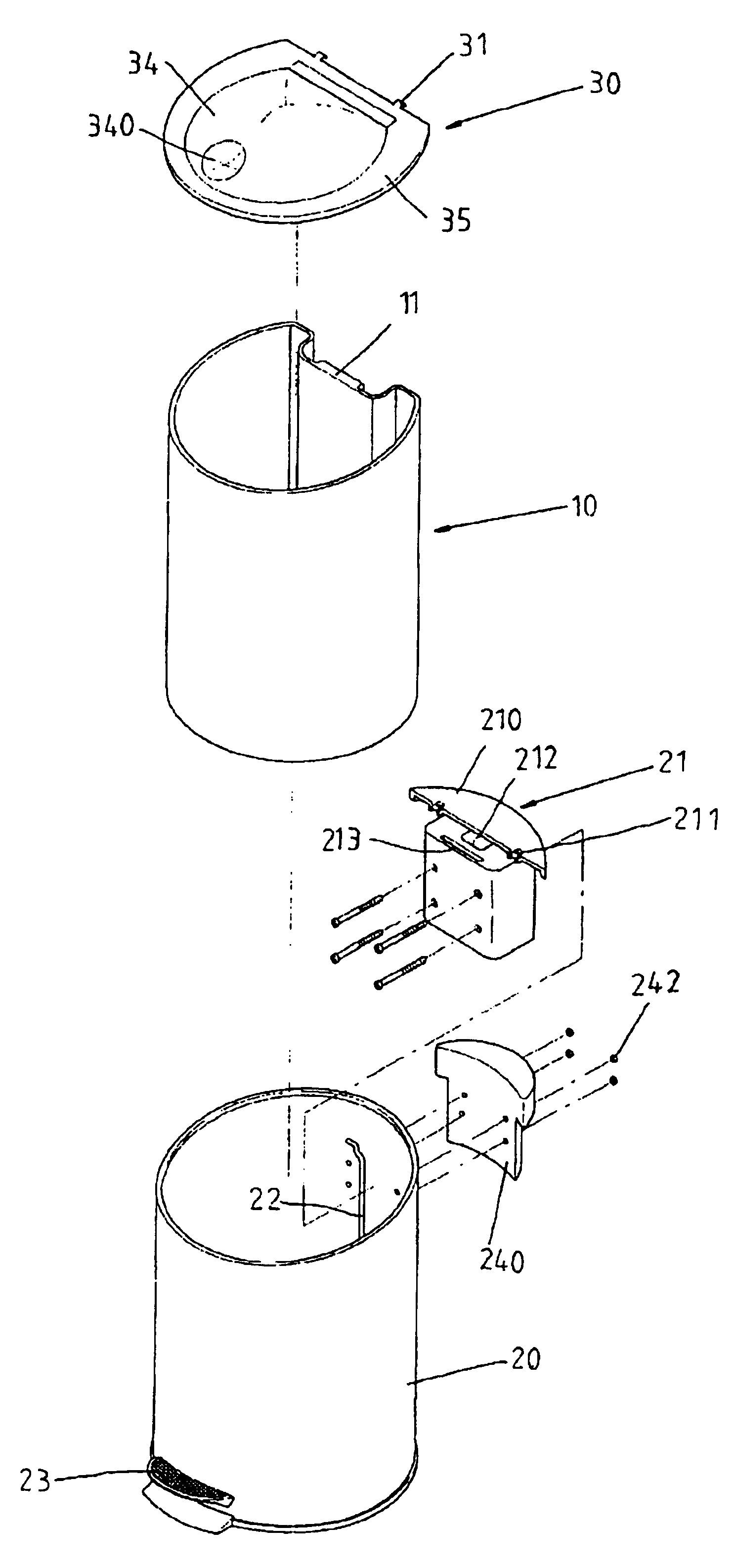

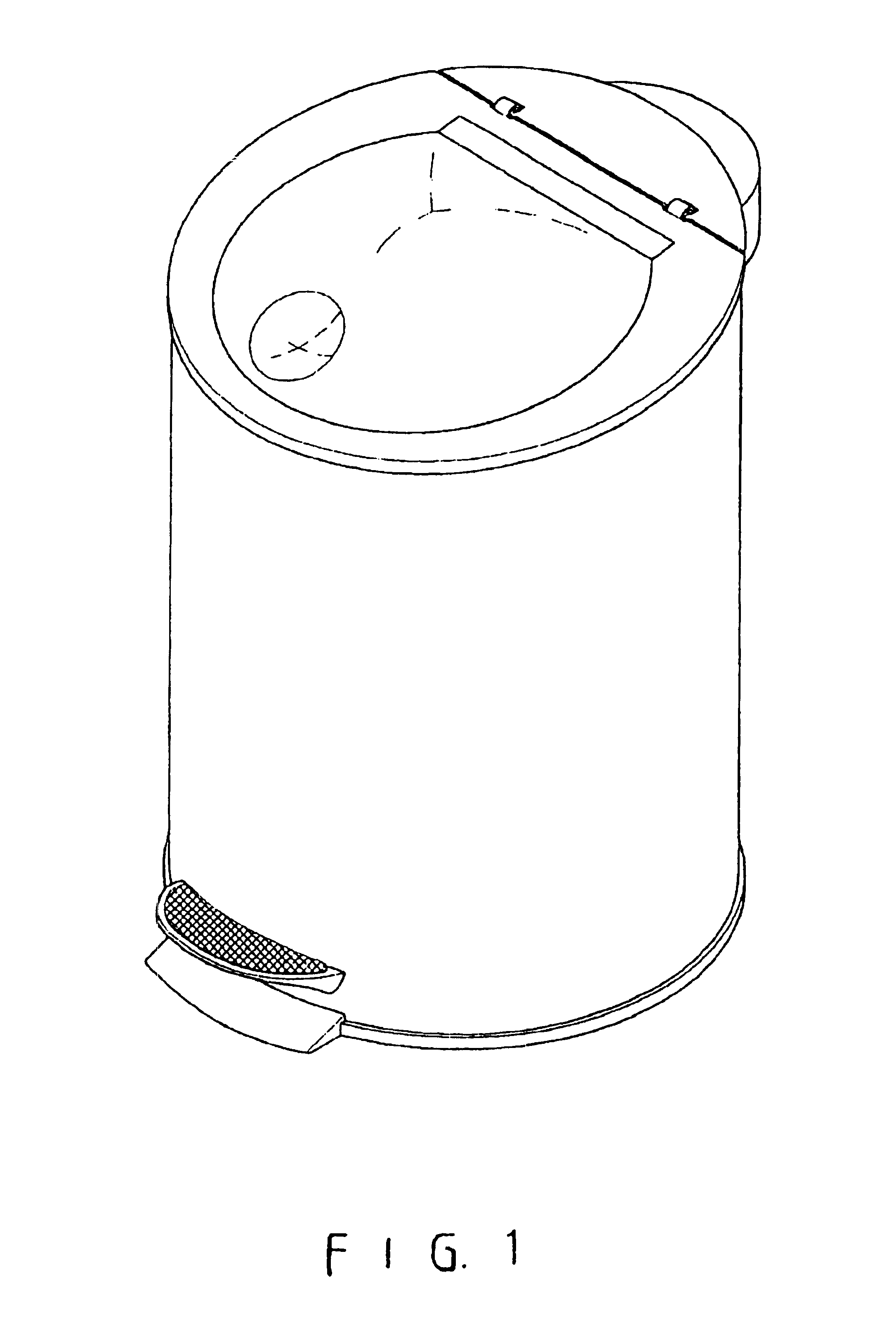

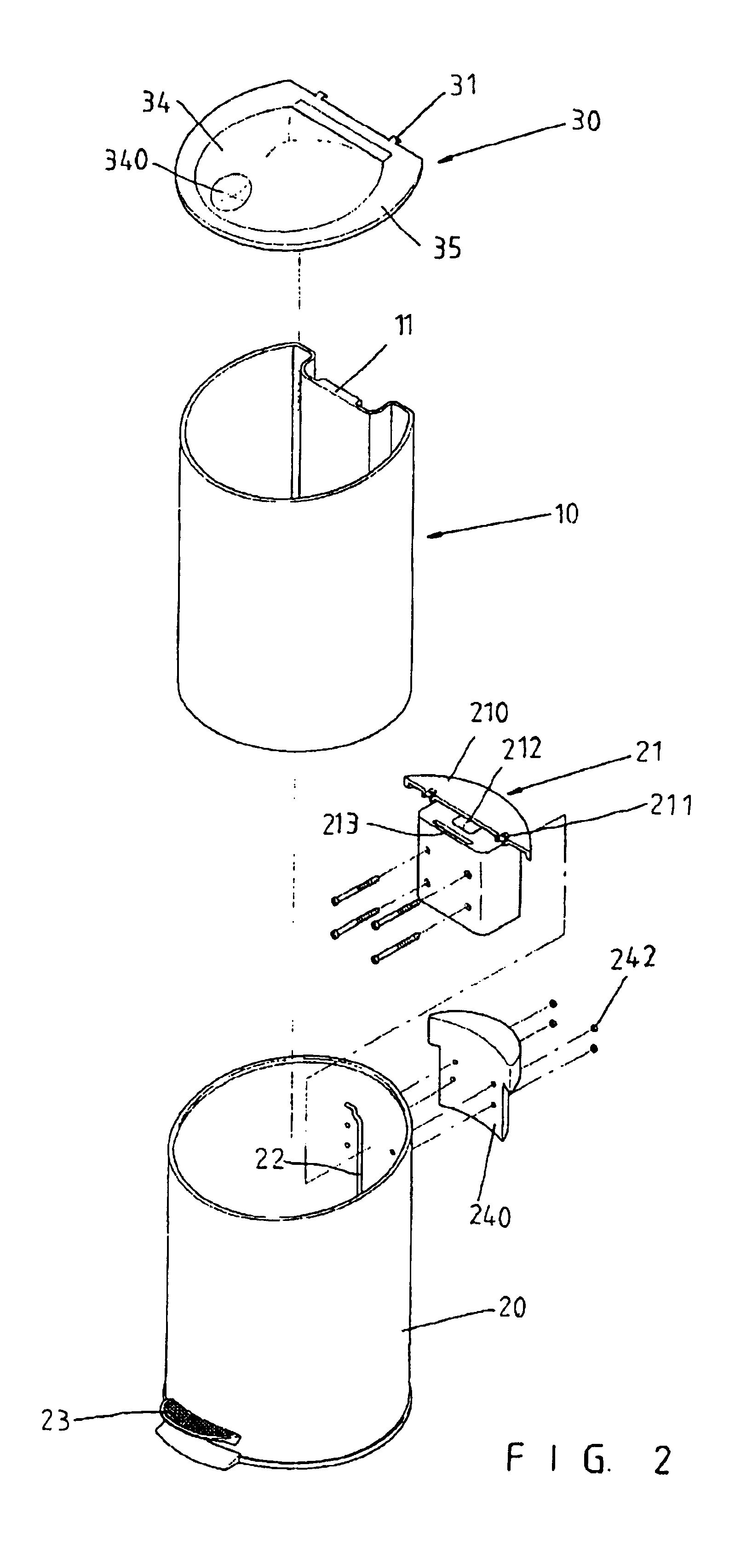

[0033]Referring to the drawings and initially to FIGS. 1-6, a waste bin structure in accordance with the present invention comprises an inner barrel 10, an outer barrel 20, and a barrel lid 30. The inner barrel 10 is received in the outer barrel 20. A connecting portion 21 is mounted on the rear end of the inner rim of the outer barrel 20. The connecting portion 21 has a top face integrally formed with a cover 210. The cover 210 has a front end provided with two hanging shafts 211. The barrel lid 30 has a distal end provided with two hanging ears 31 each snapped on the hanging shaft 211 of the cover 210 so that the barrel lid 30 covers the top edge of the outer barrel 20. The barrel lid 30 is provided with a locking portion 32 that is opened and closed by a triggering action, so that the barrel lid 30 can be opened by the triggering action. The connecting portion 21 of the outer barrel 20 has a center defining a channel 212. A linking lever 22 is received in the channel 212 and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com