System and method for analyzing modeling accuracy while performing reverse engineering with 3D scan data

a technology of reverse engineering and modeling accuracy, applied in the field of cad (computer aided design), can solve problems such as inaccurate data, and achieve the effect of updating the accuracy loss information availabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

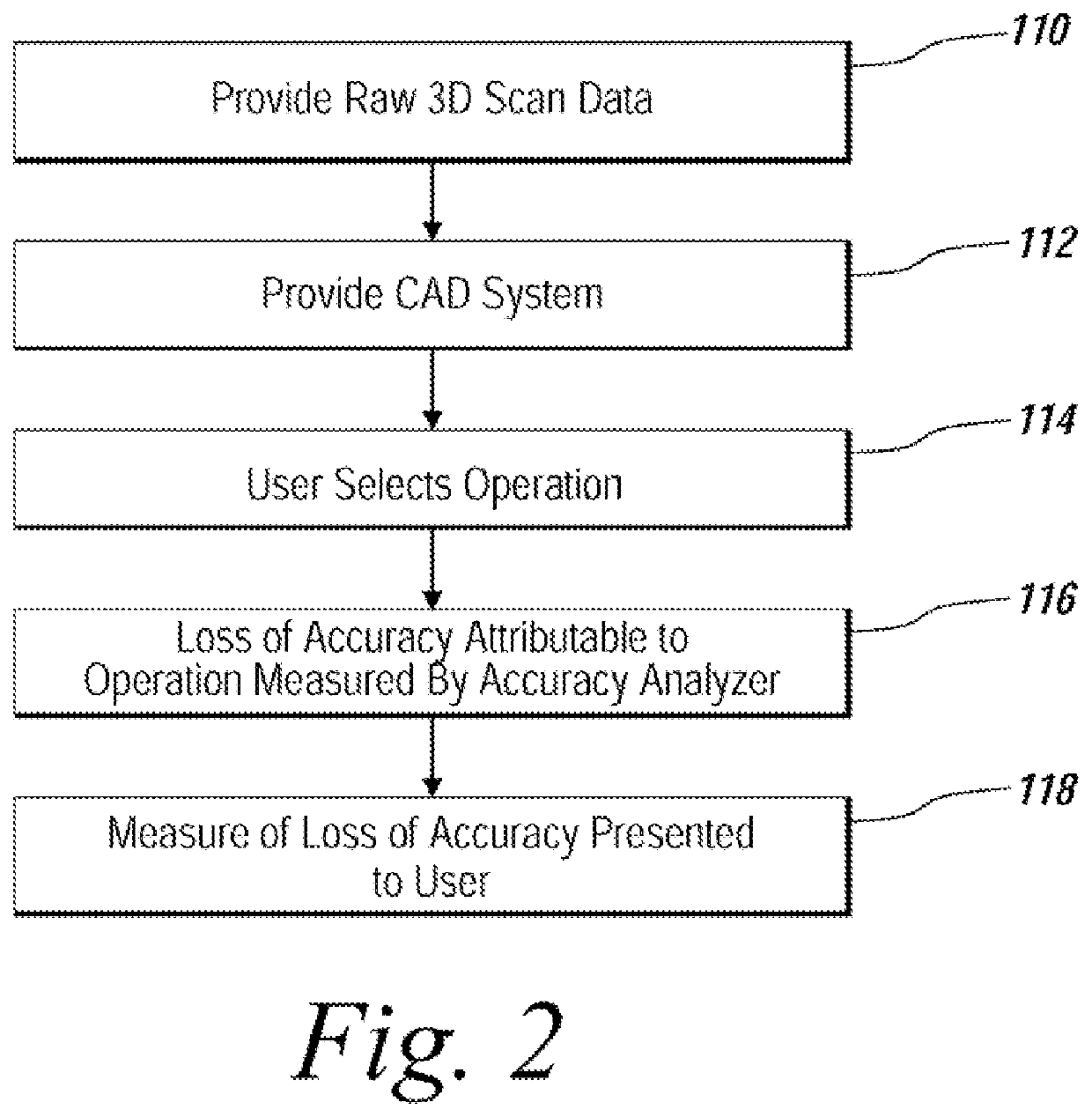

[0028]The embodiments of the present invention provides accuracy loss information to a user performing reverse engineering using 3D scan data. The accuracy loss information indicates the effect of scan data editing operations or CAD remodeling operations on 3D scan data. Accuracy loss indicates the distance deviation between a chosen reference 3D scan data (e.g.: the original scan data or the previous state of the 3D scan data prior to modification) and the modified raw 3D scan data or a derivative of the 3D scan data such as a surface or solid body. Changes to the reference scanned data that have been or will be caused by a scan data editing or CAD remodeling operation are noted for a user. In one implementation, the effect of a proposed operation is presented to the user in a preview pane before the operation is completed.

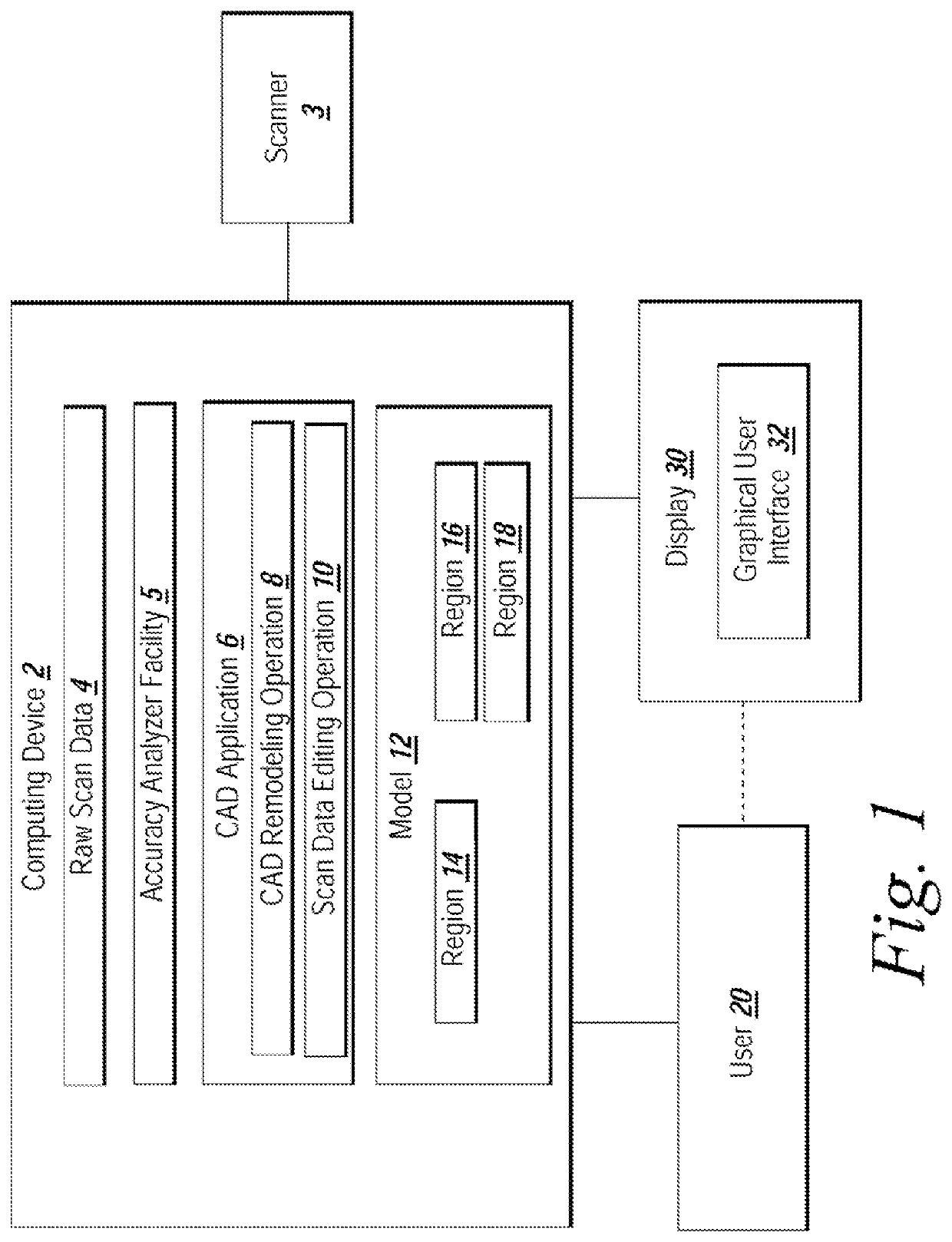

[0029]FIG. 1 depicts an environment suitable for practicing an embodiment of the present invention. A computing device 2 includes a collection of raw 3D scan dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com