Fluid injection nozzle

A technology of liquid injection and nozzle, which is applied to the cleaning method using liquid, the device for coating liquid on the surface, and the spraying device, etc., which can solve the problems of reducing processing efficiency, substrate vibration, and liquid injection not in the predetermined direction, etc., to achieve Effect of reducing defects and preventing contact between nozzle and surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, preferred embodiments of the present invention illustrated in the accompanying drawings will be described in detail. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

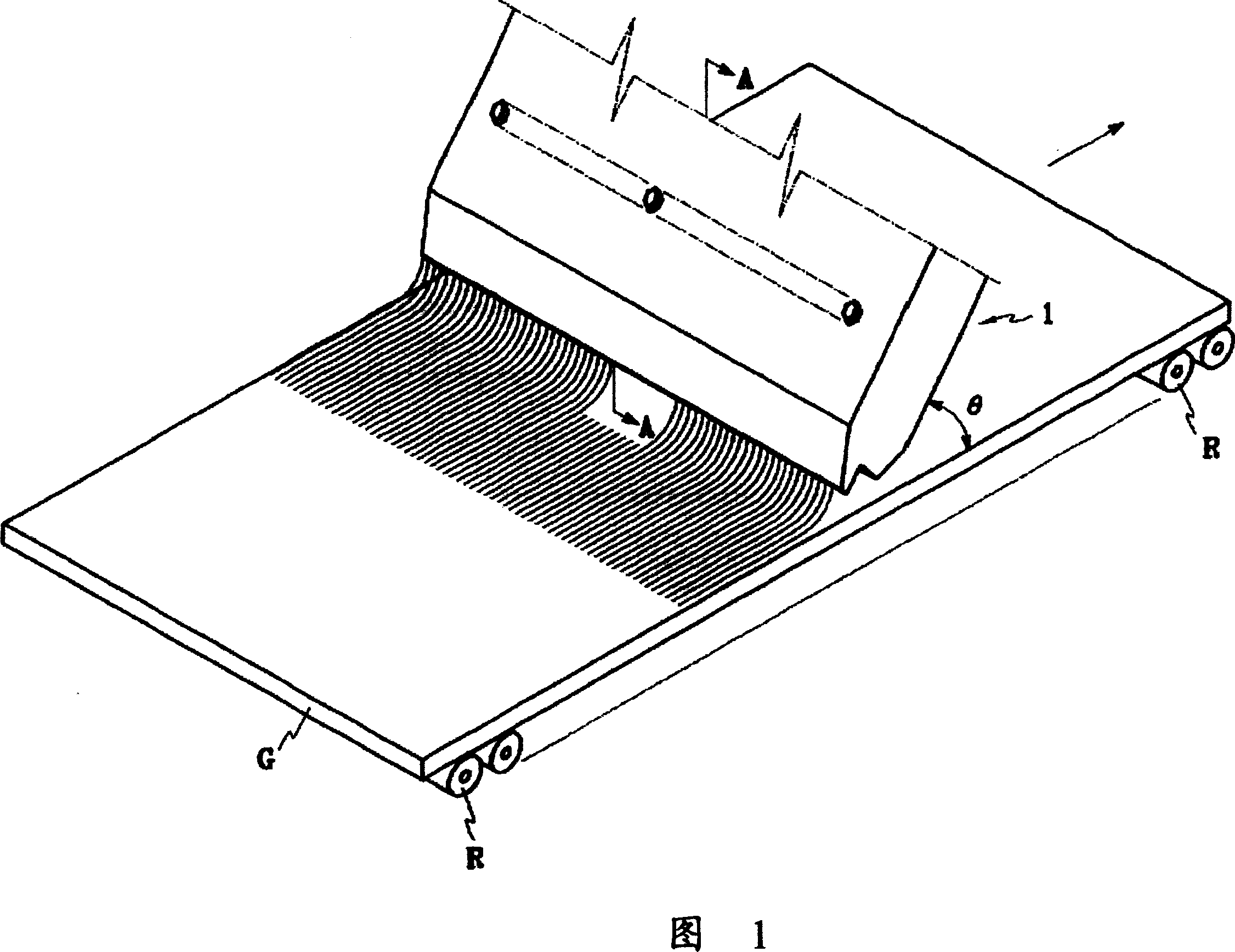

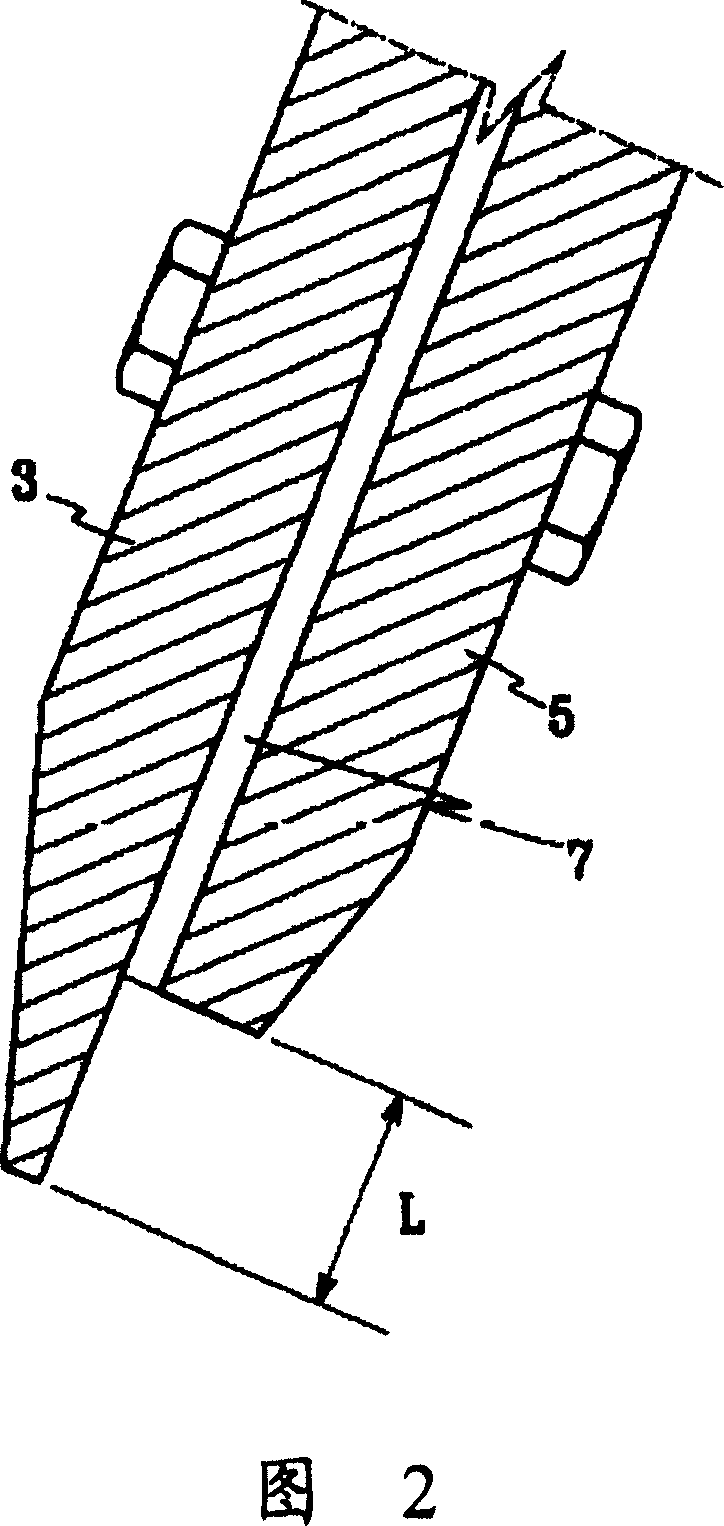

[0016] 1 and 2 show a liquid injection nozzle according to a preferred embodiment of the present invention.

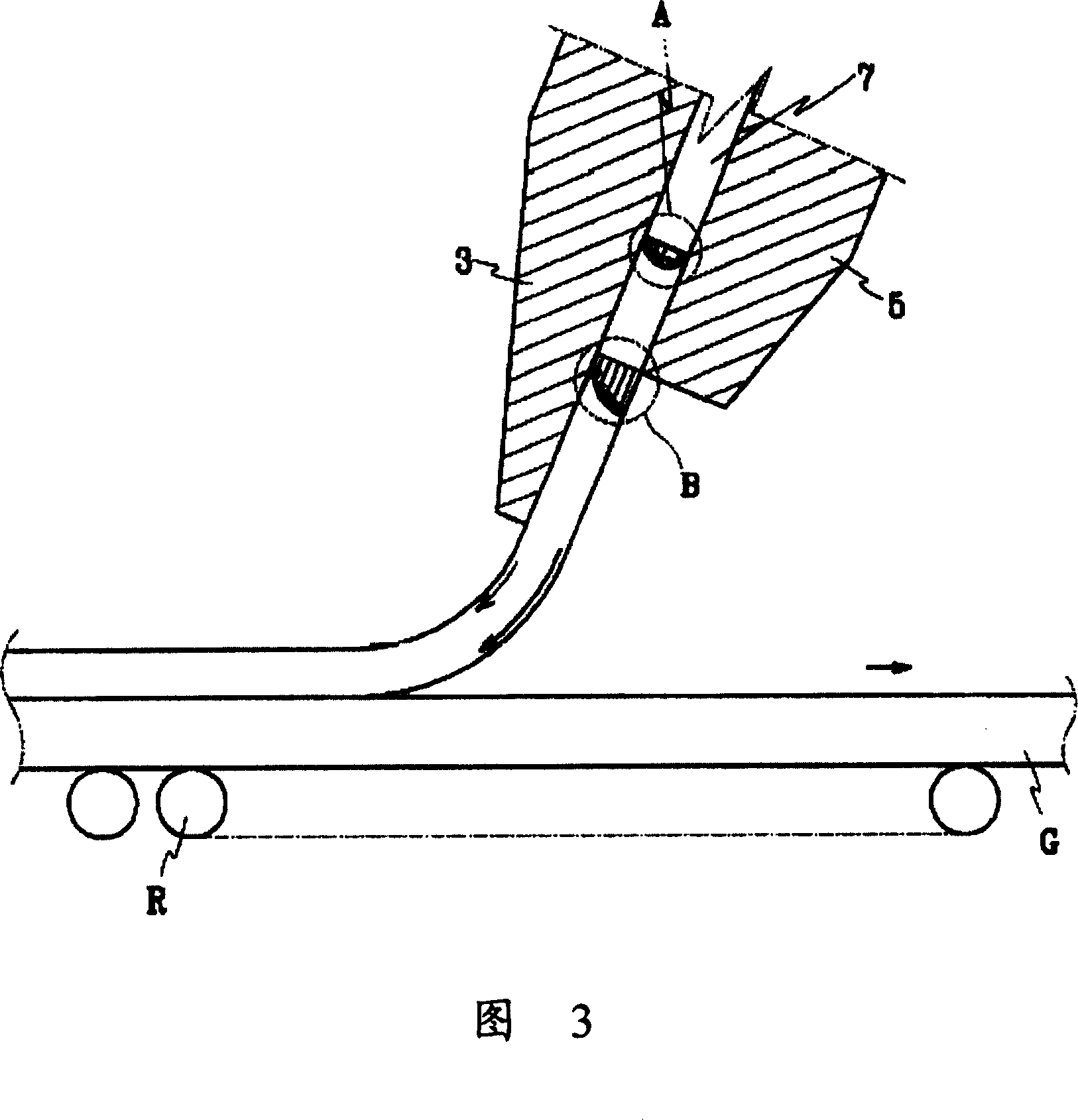

[0017] The liquid injection nozzle 1 of the present invention is placed obliquely at a predetermined angle θ with respect to the surface of the substrate G. As shown in FIG.

[0018] The nozzle 1 includes a first plate 3 and a second plate 5 each having a predetermined width. The first plate 3 and the second plate 5 are connected to each other by fasteners such as screw / nut sets, between which a liquid channel 7 is defined. The length of the tip portion of the second plate 5 is shorter by L than the length of the tip portion of the first plate 3 . Furthermore, preferably, the second plate 5 is placed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com