Movable microscope for detecting real-time welding of laser welding machine

A microscope and prism technology, applied in laser welding equipment, microscopes, welding equipment, etc., can solve the problems of weakening laser welding, impracticability, and inaccurate welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

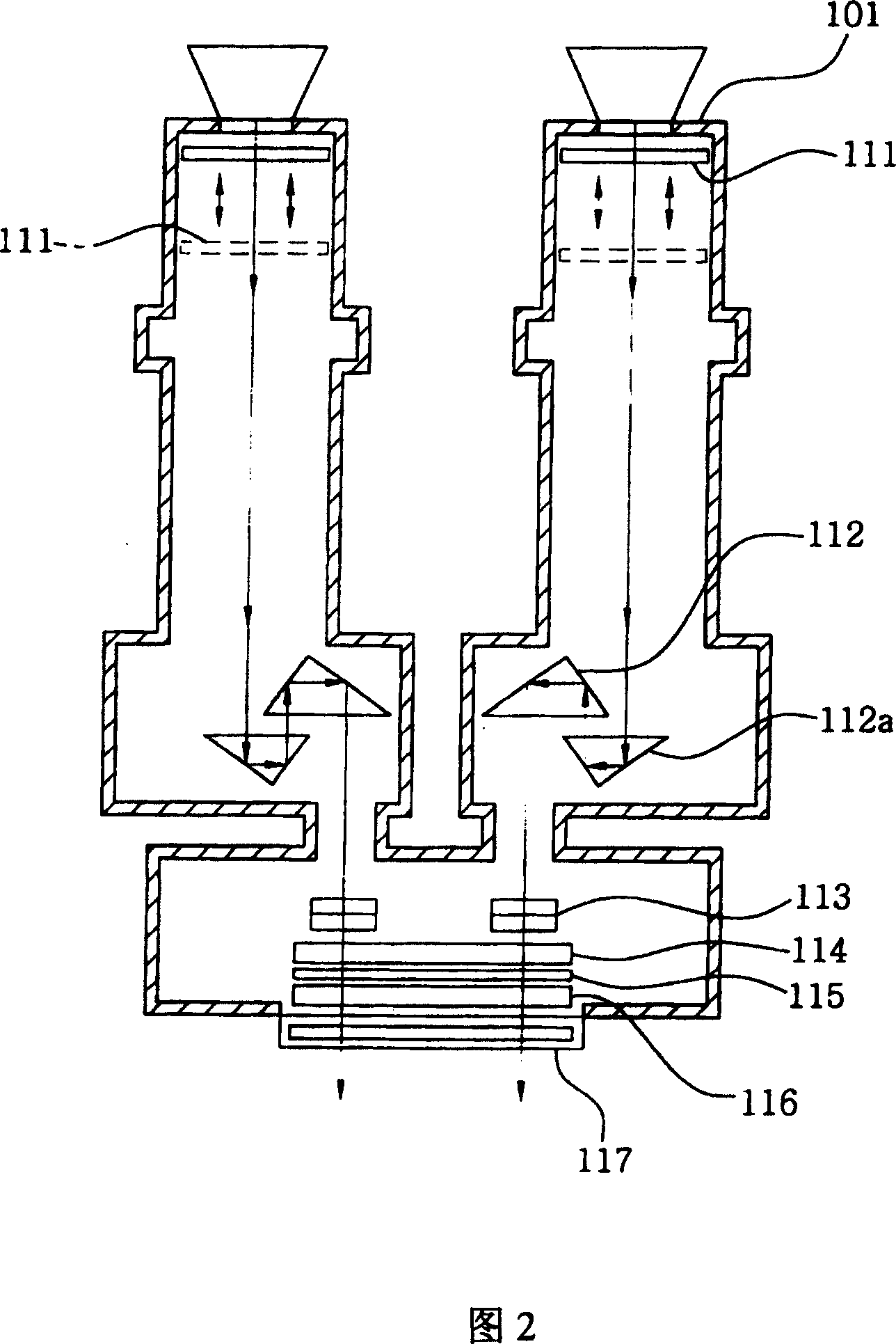

[0023] 1 is a schematic diagram illustrating the structure of a microscope connected to a flexible arm of a laser welding machine according to the present invention, and FIG. 2 is an enlarged view illustrating the structure of the microscope in FIG. 1 .

[0024] Referring to FIG. 2, the laser welding machine microscope includes a main body 101, an eyepiece 111, two pairs of prisms 112 and 112a, an objective lens 113, a liquid crystal (LC) shutter 114, a filter lens 115, a total reflection lens 116, and safety glass 117.

[0025] The main body 101 has a pair of integrally formed tubes, allowing a person to observe the welded object with both eyes simultaneously. The eyepiece 111 is movably installed in the tube of the main body 101 for adjusting the magnification of the microscope by moving up and down. Each pair of prisms 112 and 112a is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com