Axle sleeve structure

A technology of bushings and rubber shafts, which is applied to cantilever mounted on pivots, springs made of plastic materials, suspensions, etc., can solve the problems of increasing the weight of rubber bushings and increasing the size of rubber bushings, and achieve Lightweight and miniaturized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

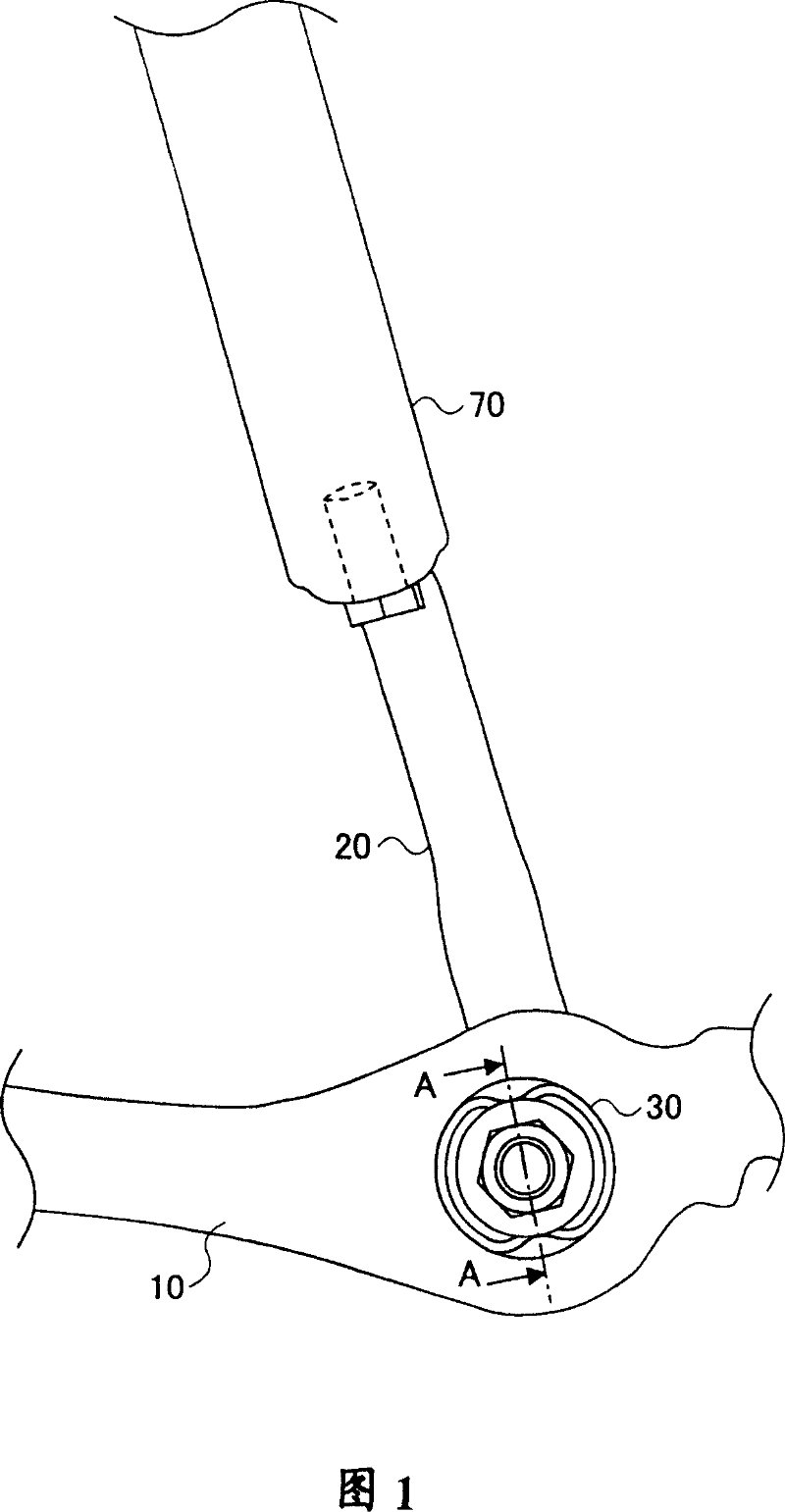

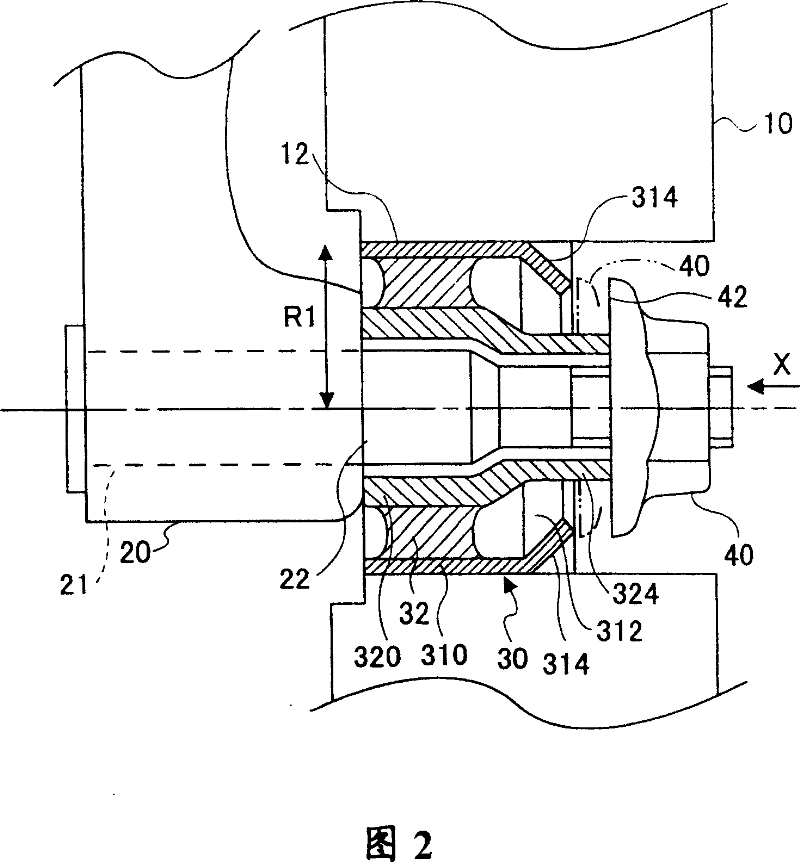

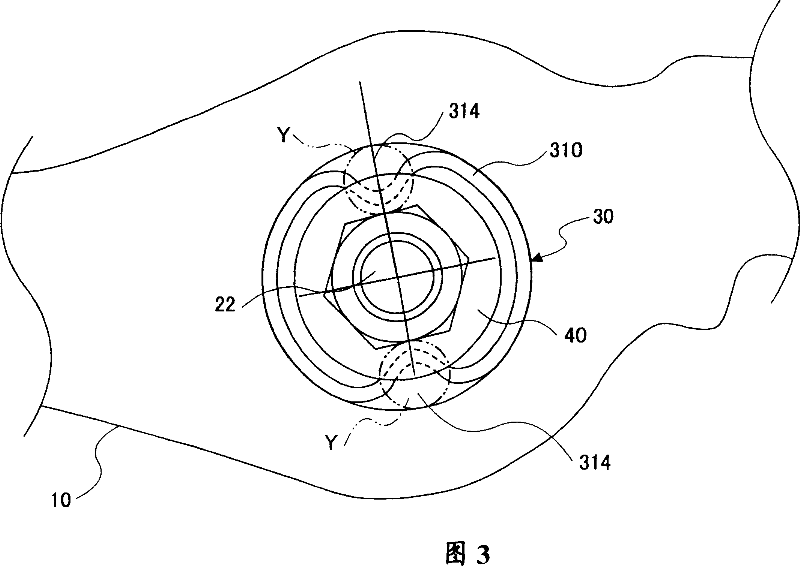

[0023] Fig. 1 is a front view showing a main part of a vehicle suspension structure according to a first embodiment of the present invention.

[0024] The suspension structure shown in FIG. 1 has a suspension arm (lower arm) 10 which can rockably support the wheel on the vehicle body. The suspension arm 10 is connected to the wheel through a ball joint, a knuckle arm, a bearing, a hub, and the like.

[0025] The suspension arm bracket 20 is fastened to the suspension arm 10 via a rubber bush 30 . The suspension arm bracket 20 is engaged with one end of a shock absorber 70 by a bolt or the like. The other end of the shock absorber 70 is fixed on the vehicle body.

[0026] In the above suspension structure, the vertical vibration of the wheel due to the force applied to the wheel from the road is absorbed by the shock absorber 70 mainly through the suspension arm 10 and the suspension arm bracket 20 .

[0027] As an embodiment of the present invention, the fastening structure...

no. 2 Embodiment

[0047] Fig. 5 is a cross-sectional view showing a suspension structure of a second embodiment of the present invention.

[0048] The difference between this embodiment and the first embodiment is that in this embodiment, the suspension arm 10 and the suspension arm bracket 20 are connected together by bolts 50 . Except for this point, other structures may be the same as those of the first embodiment.

[0049] In FIG. 5 , instead of the pin 22 , the shaft portion of the bolt 50 is inserted into the inner cylinder 320 of the rubber bush 30 . The inner cylinder 320 may also have a small diameter portion 324 , and more importantly, the inner diameter of the inner cylinder 320 is substantially consistent along the entire circumferential direction in the axial direction. As shown in FIG. 5 , the bolt 50 may be threaded with a nut 52 or the like, or alternatively may be threaded in the hole 21 of the suspension arm bracket 20 .

[0050] In this embodiment, as shown in FIG. 5 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com