Temperature sensor of long period optical fiber grating

A long-period grating and optical fiber grating technology, which is applied in the field of temperature sensing devices and long-period optical fiber grating temperature sensing devices, can solve the problems of low modulation degree and low temperature sensitivity, and achieve good stability, high temperature sensitivity, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

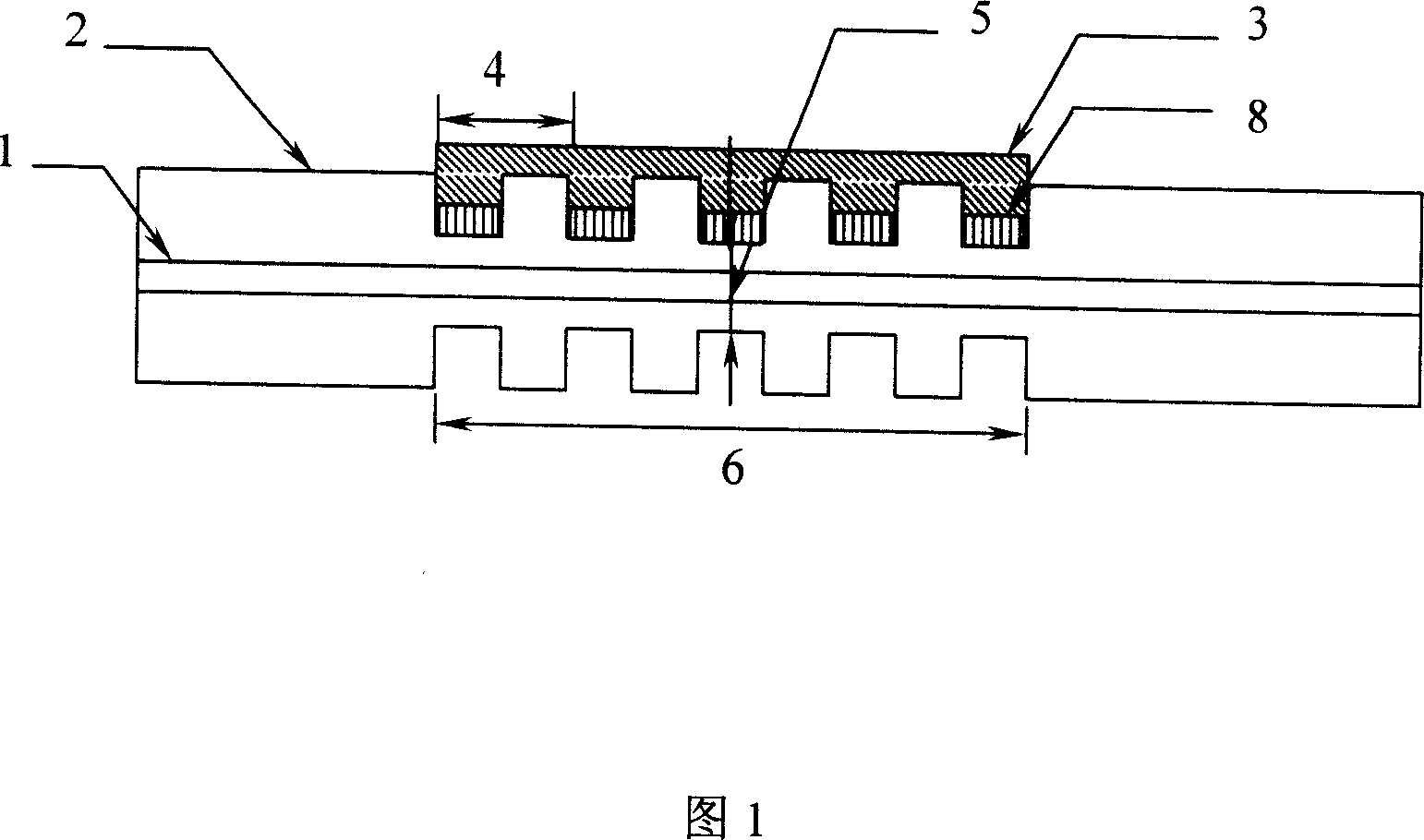

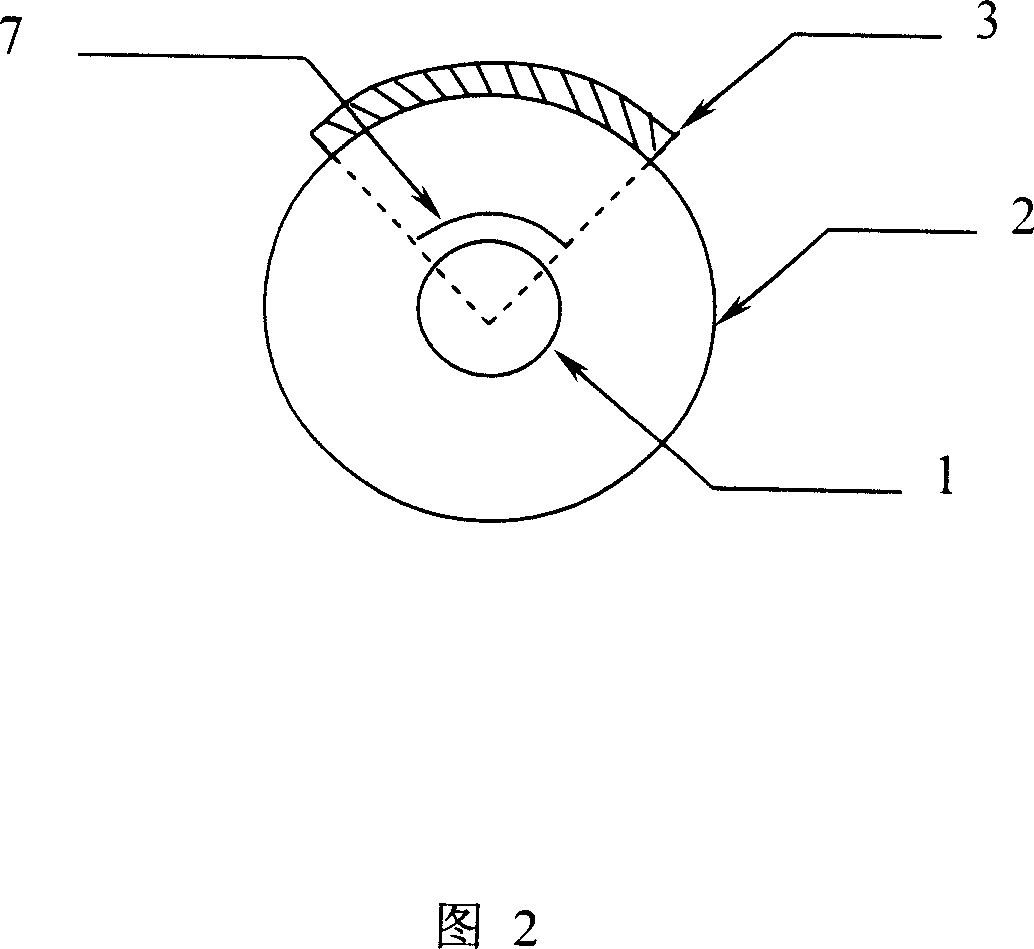

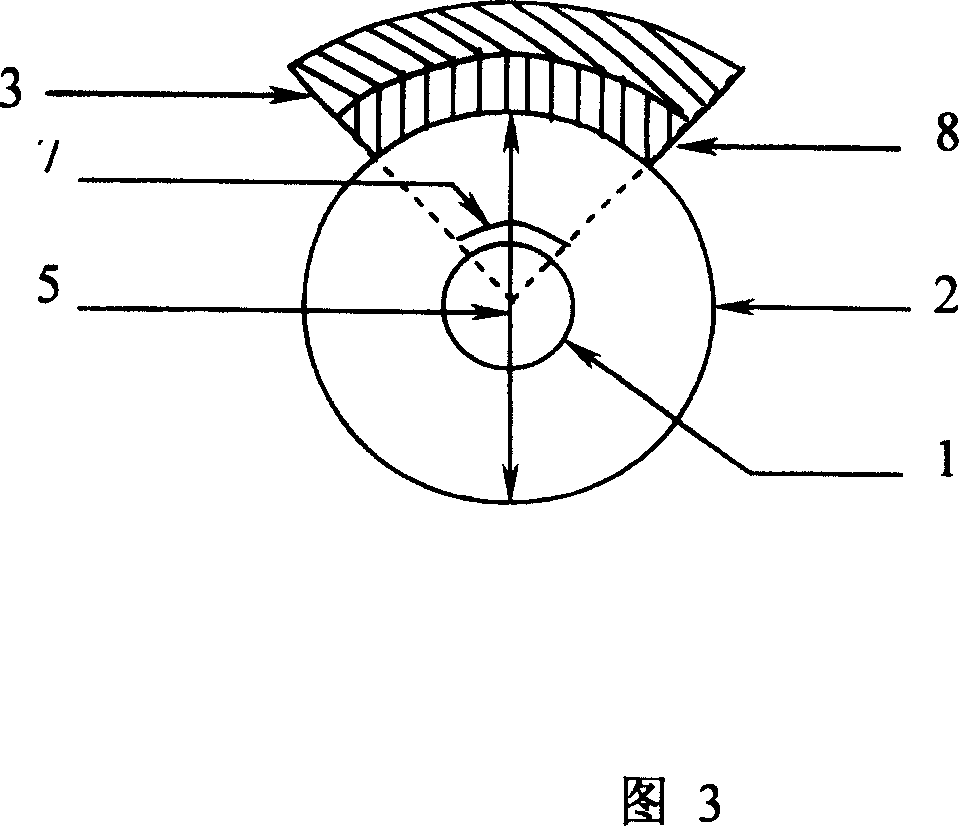

[0019] An embodiment of the present invention is shown in FIG. 1 . As can be seen from the figure, the temperature sensing device of the long-period fiber grating of the present invention is composed of: on the single-mode fiber cladding 2 written with the long-period grating, one side of the fiber grating is plated from the inside to the outside along the axial direction. There are low thermal expansion coefficient coating layer 8 and high thermal expansion coefficient coating layer 3 . The period 4 of the long-period grating is 500-900 μm, the cladding diameter after etching is 65-85 μm, and the total length 6 of the grating is 40-60 mm. The central angle corresponding to the low thermal expansion coefficient coating layer 8 and the high thermal expansion coefficient coating layer 3 is 60-120°, and the thickness of the low thermal expansion coefficient coating layer is 20-30 μm. The long-period fiber grating can be realized by photolithography and etching, and the coating l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com