Naval propulsion system feeding by garbage derived fuel and its method

A propulsion system and fuel technology, applied in the direction of combustion method, fuel supply, solid fuel pretreatment, etc., to achieve the effect of increasing navigation speed and great economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

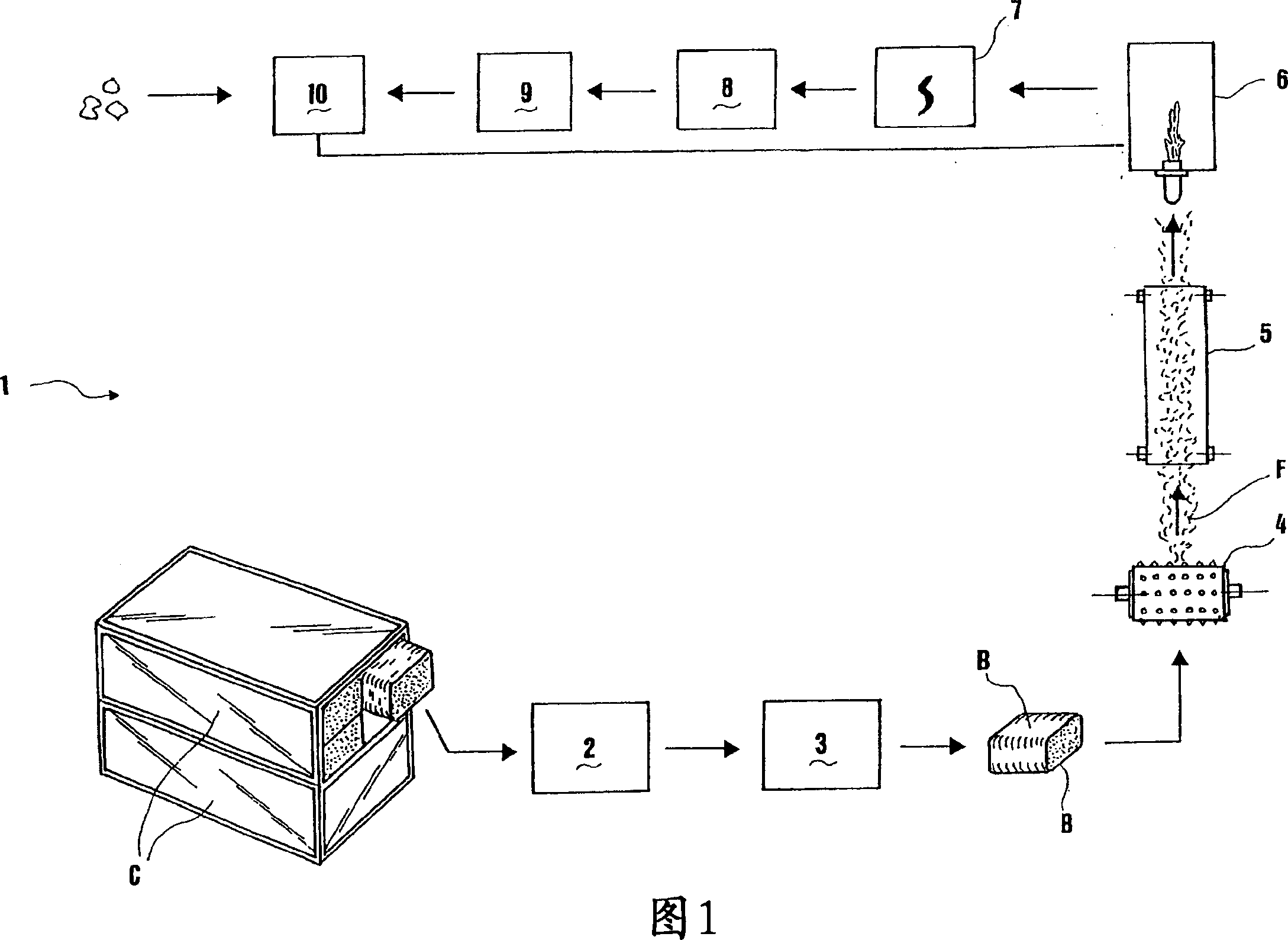

[0018] Referring first to FIG. 1 , a marine propulsion system suitable for feeding with CNC (ie non-conventional fuels from garbage and / or production waste, see definition provided above) is indicated generally at 1 .

[0019] The system 1 is suitable for generating thermomechanical work, in particular steam.

[0020] In this embodiment, the CNC provided by the propulsion system 1 is solid and supplied in packages.

[0021] The system 1 includes the following main units:

[0022] - container means 2 for container (container) C;

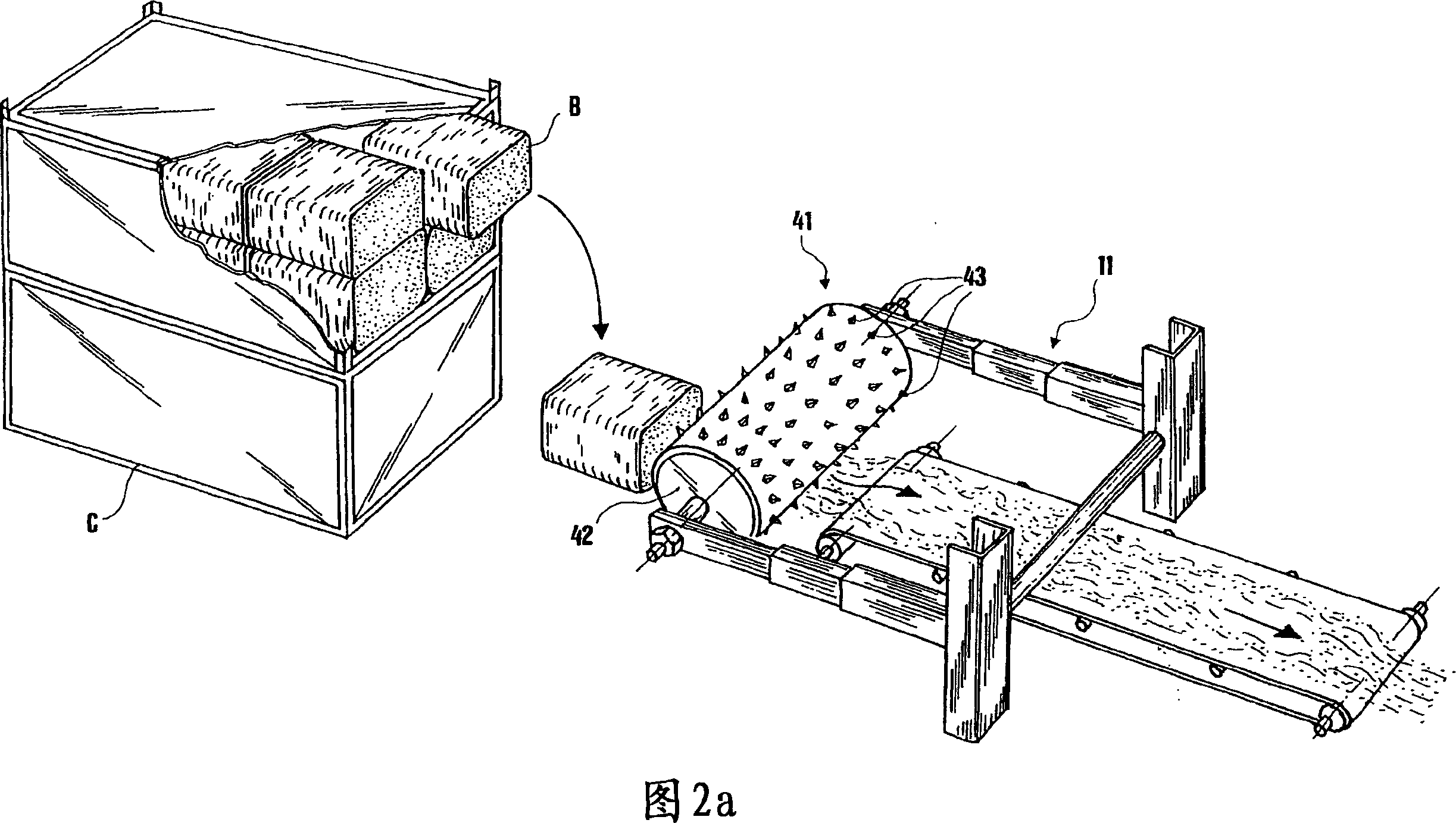

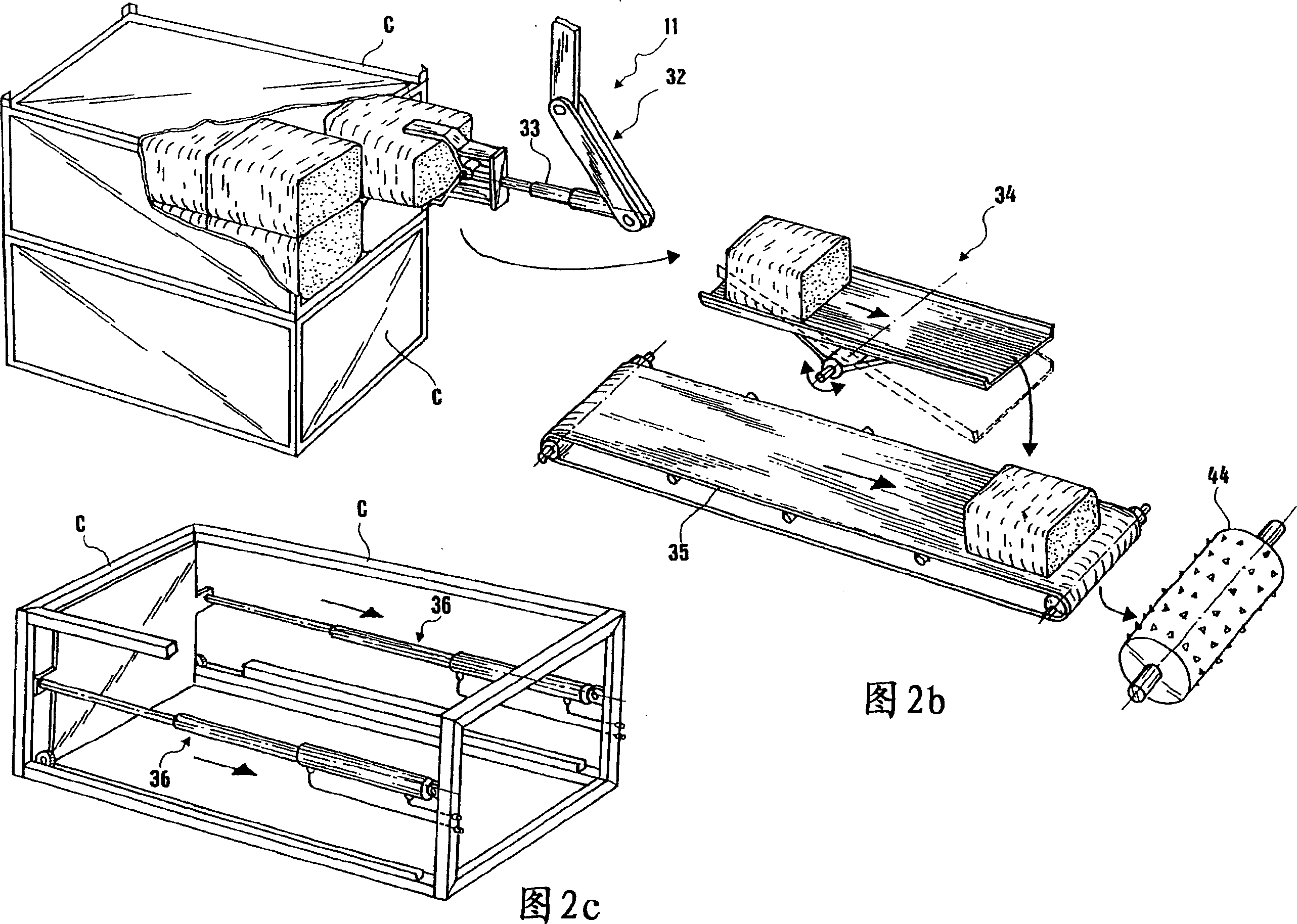

[0023] - extraction unit for extracting the CNC package B from the container, said container being arranged in said containment device 2, said extraction unit being all denoted by number 3 in FIG. 1;

[0024] - a reduction unit for reducing the aforementioned package to shredded form, the so-called "fluff" (fluff) form F, said reduction unit being denoted in its entirety by number 4 in FIG. 1 ;

[0025] - conveying means 5 for conveying the CNC in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap