Device for measuring the injection amount in injection systems and method for production thereof

A technology of injection system and injection quantity, applied in the direction of measurement device, fuel injection device, charging system, etc., can solve the problems of measurement results and measurement accuracy change, impossible measurement, slow decay, etc., to improve measurement accuracy and improve stability. , the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

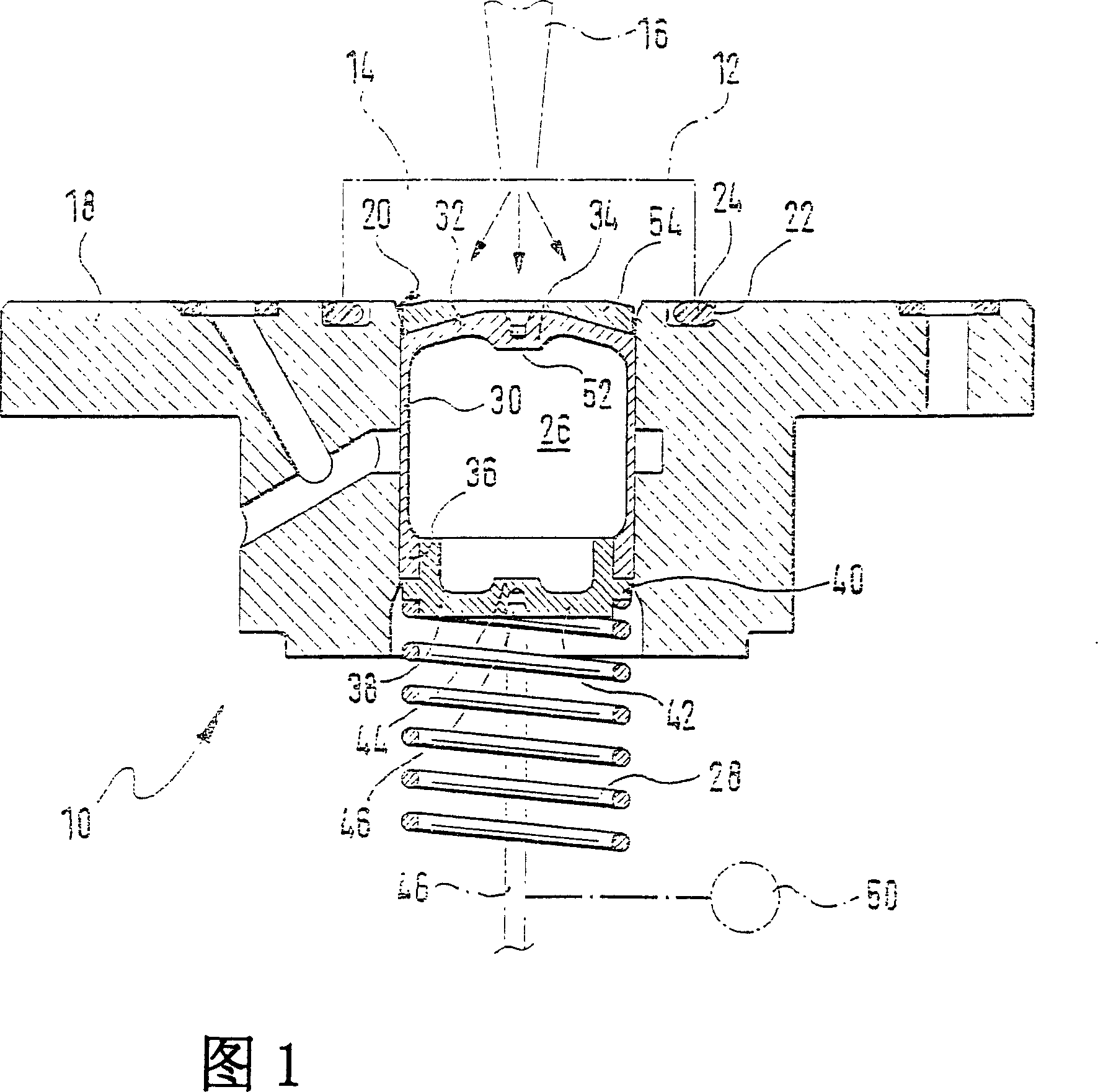

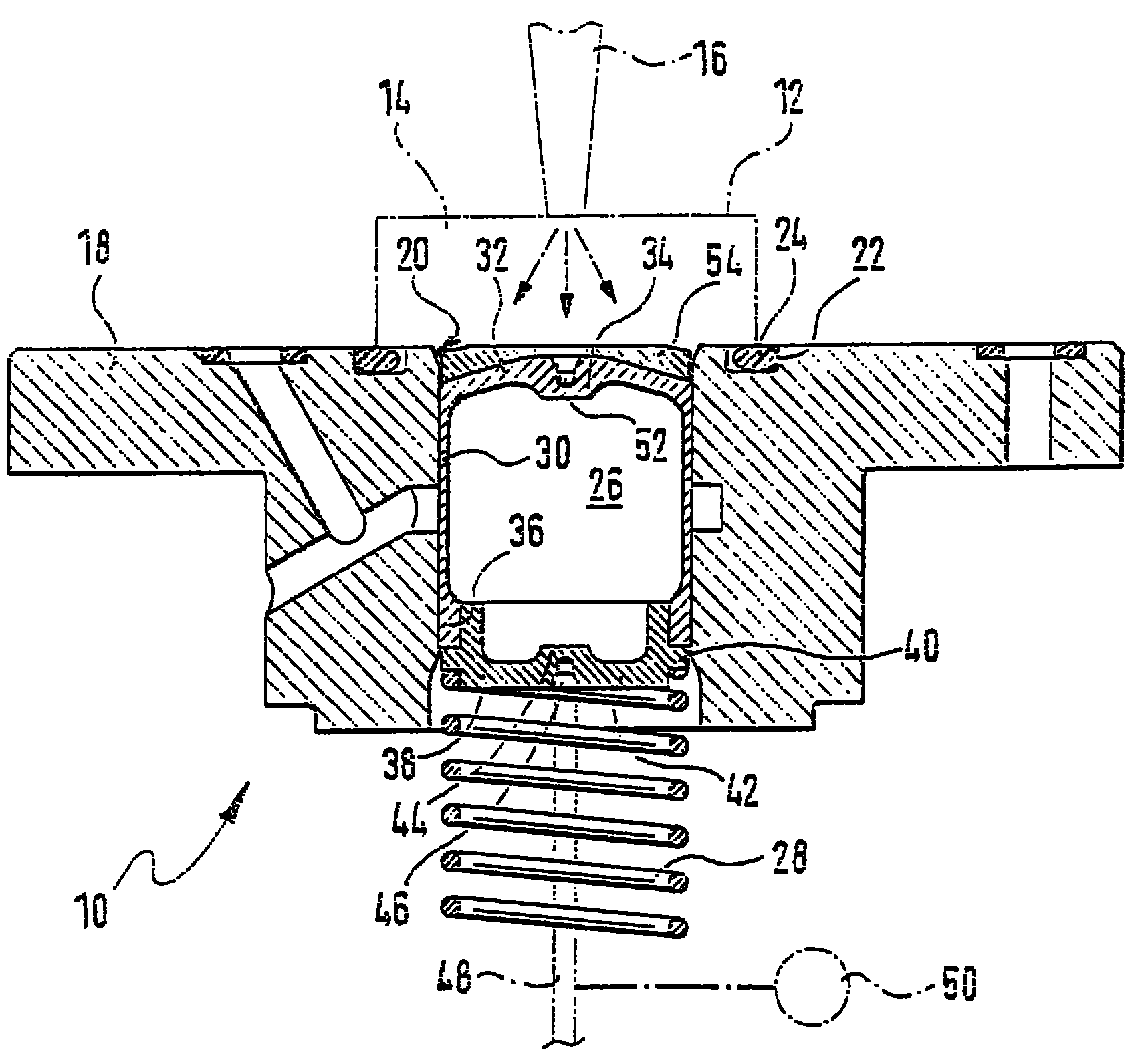

[0021] Said device is referenced 10 in FIG. 1 . It comprises a measuring chamber 14 formed in a housing 12 , to which a nozzle 16 is connected in a sealing manner. In this figure the housing 12, the measuring chamber 14, and the nozzle 16 are only schematically indicated with dotted lines.

[0022] On the lower side in FIG. 1 the measuring chamber 14 is bounded by a guide cylinder 18 , wherein in its plan view, ie viewed from the top in FIG. 1 , the cylinder is a cylindrical rotating part. Cylinder 18 has a concentric pilot bore 20 . An annular groove 22 is formed coaxially with the guide hole 20 in the upper surface of the cylinder 18, in which a sealing ring 24 is placed. Via this sealing ring 24 , the housing 12 forms an airtight connection with the cylinder 18 .

[0023] A piston 26 is movably held in the guide bore 20 of the cylinder 18 . The piston 26 is prestressed upwards, ie towards the measuring chamber 14 , by a spring 28 . Piston 26 essentially comprises a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com