Pipe rod screw fault detection sensor

A defect detection and sensor technology, applied in the direction of material magnetic variables, etc., can solve the problems of small detection area, uneven thread surface, no detection method, etc., and achieve the effect of ensuring precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

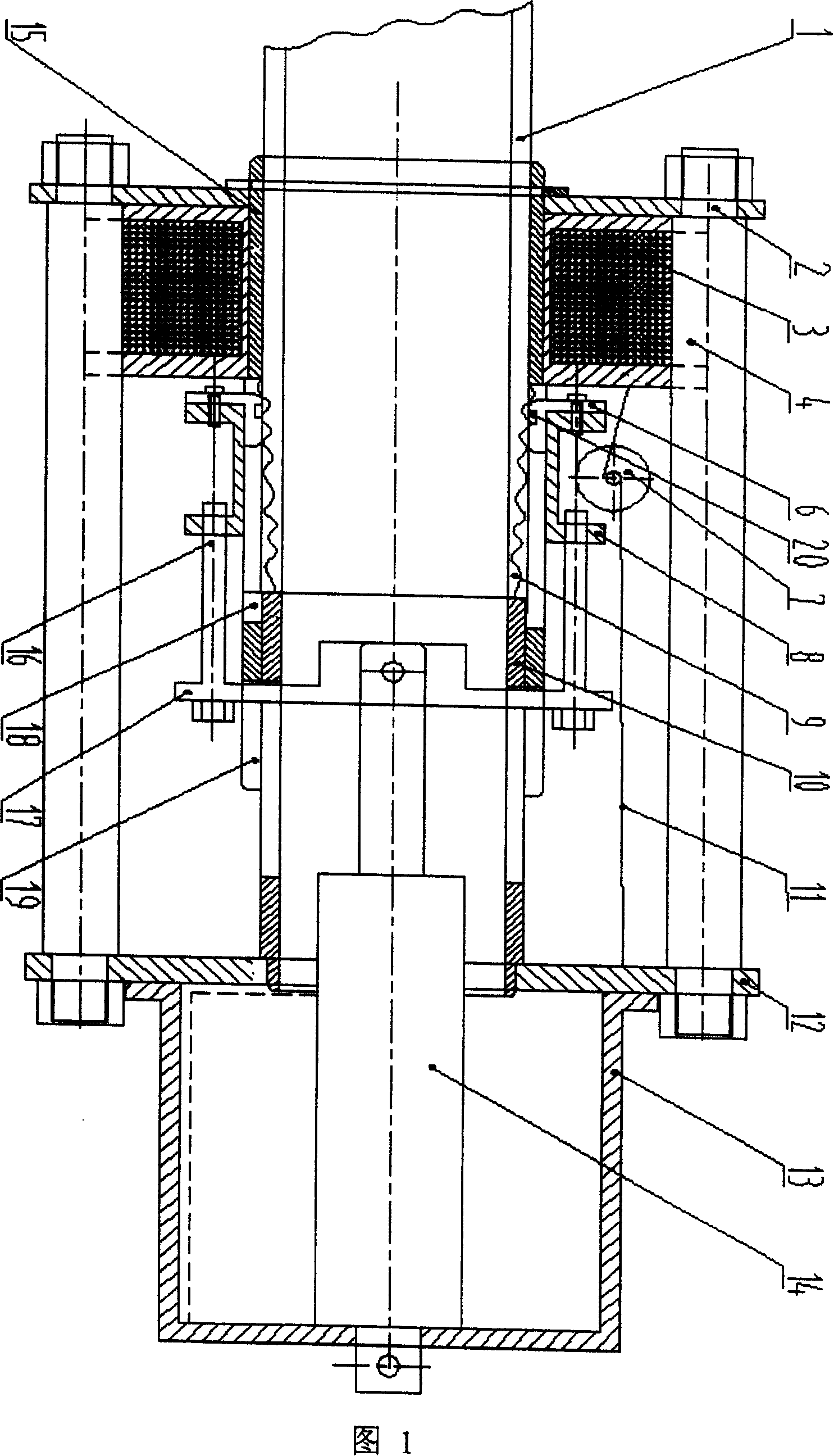

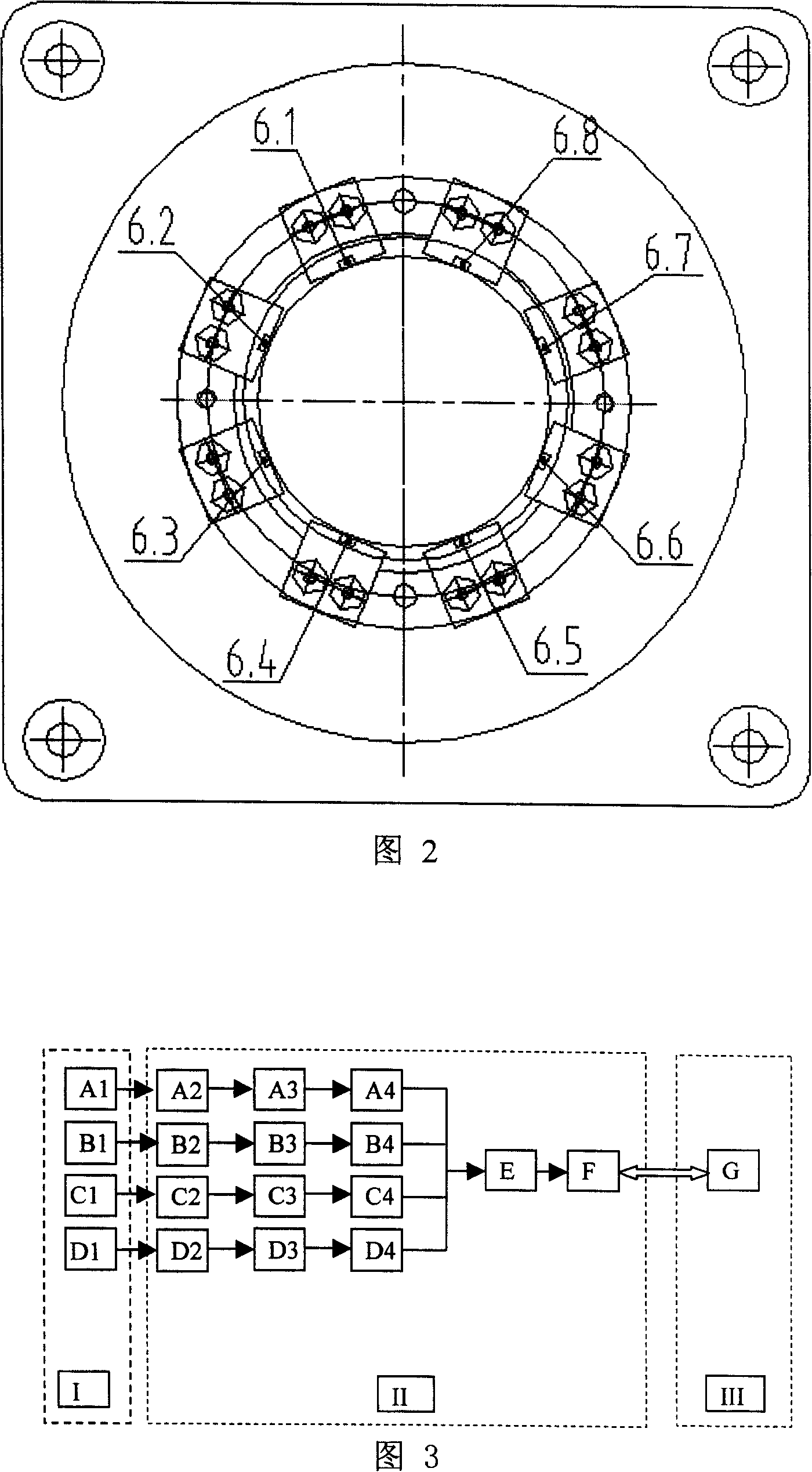

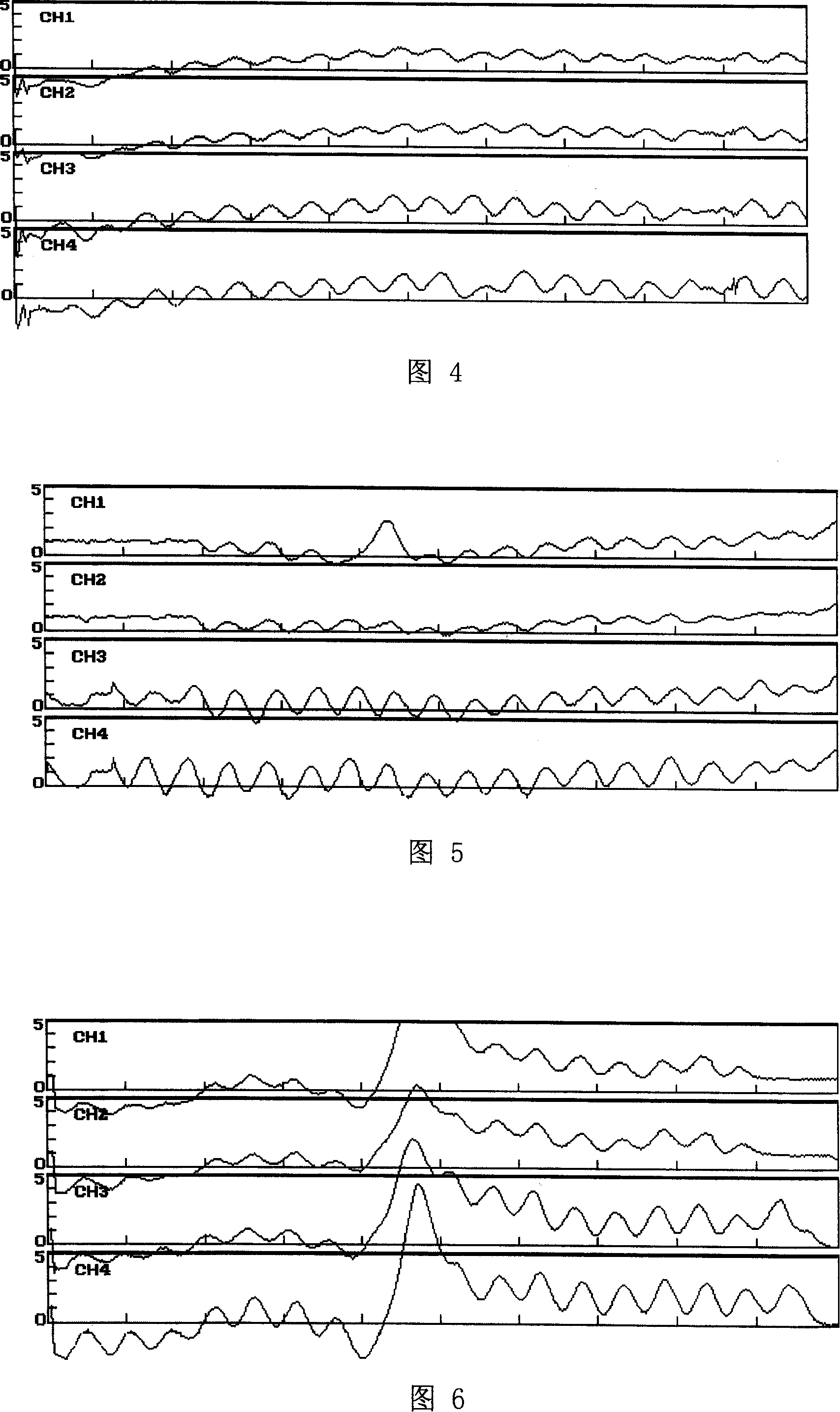

[0014] As shown in FIG. 1 , the left end of the inner sleeve 15 is equipped with a magnetizing coil 3 , and the probe frame 8 is located in the middle of the inner sleeve 15 and can slide along its outer surface. Eight probes 6 (just an even number) are floatingly installed on the probe frame 8, and are evenly and symmetrically distributed along the circumferential direction. The middle part of the inner sleeve 15 has a probe guide groove 18 with the same number of probes and corresponding positions. Each probe extends into the corresponding probe guide groove, and driven by the probe frame 8, each probe slides in the corresponding probe guide groove 18. Each probe is equipped with a magnetic induction element 20, and the magnetic induction element 20 may be a Hall element, a magnetic induction coil, or the like. Two pairs of the above two symmetrically distributed magnetic induction elements are differentially combined to output four detection signals. The positional relatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com