Method of manufacturing battery pack

A technology for battery packs and secondary batteries, which is used in battery temperature control, battery pack components, secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] best practice

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings for understanding of the present invention. Embodiment shown below is an example which actualizes this invention, and does not limit the technical scope of this invention.

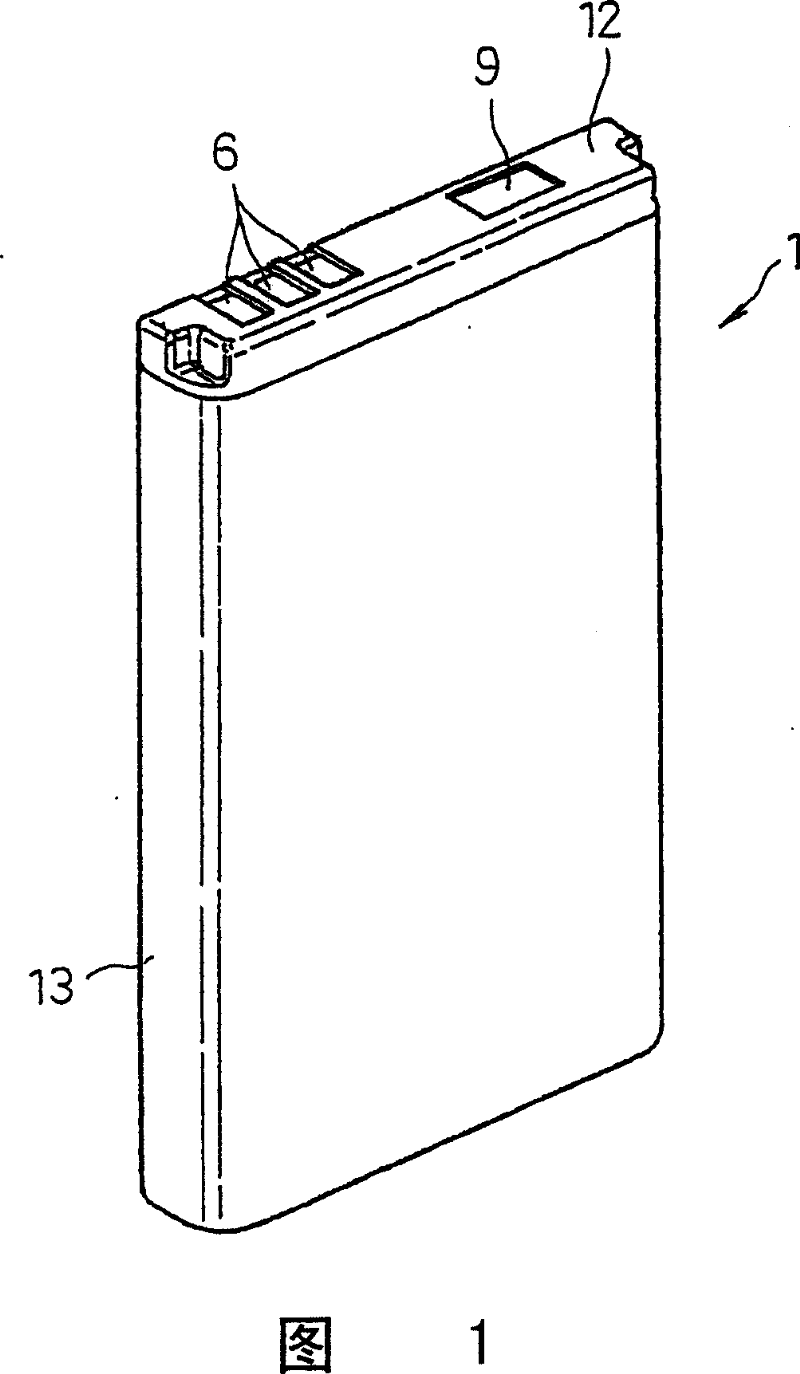

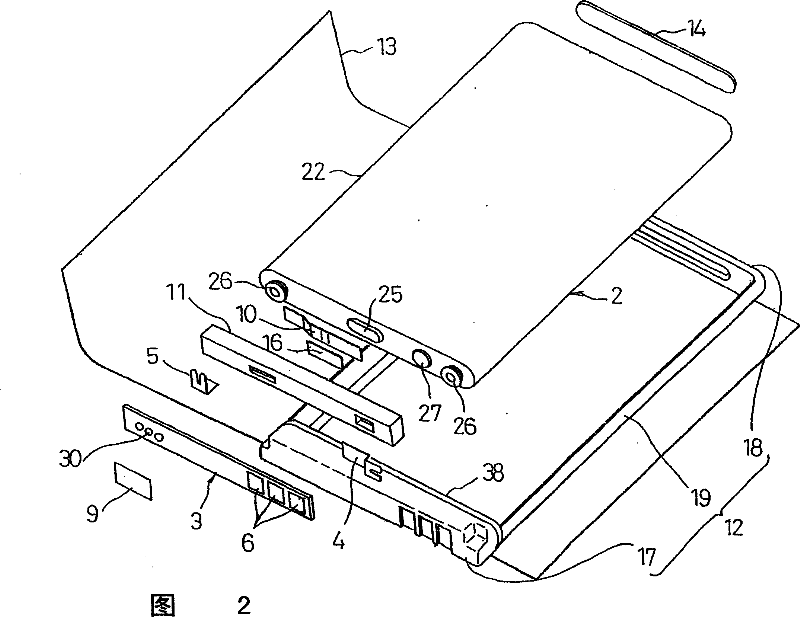

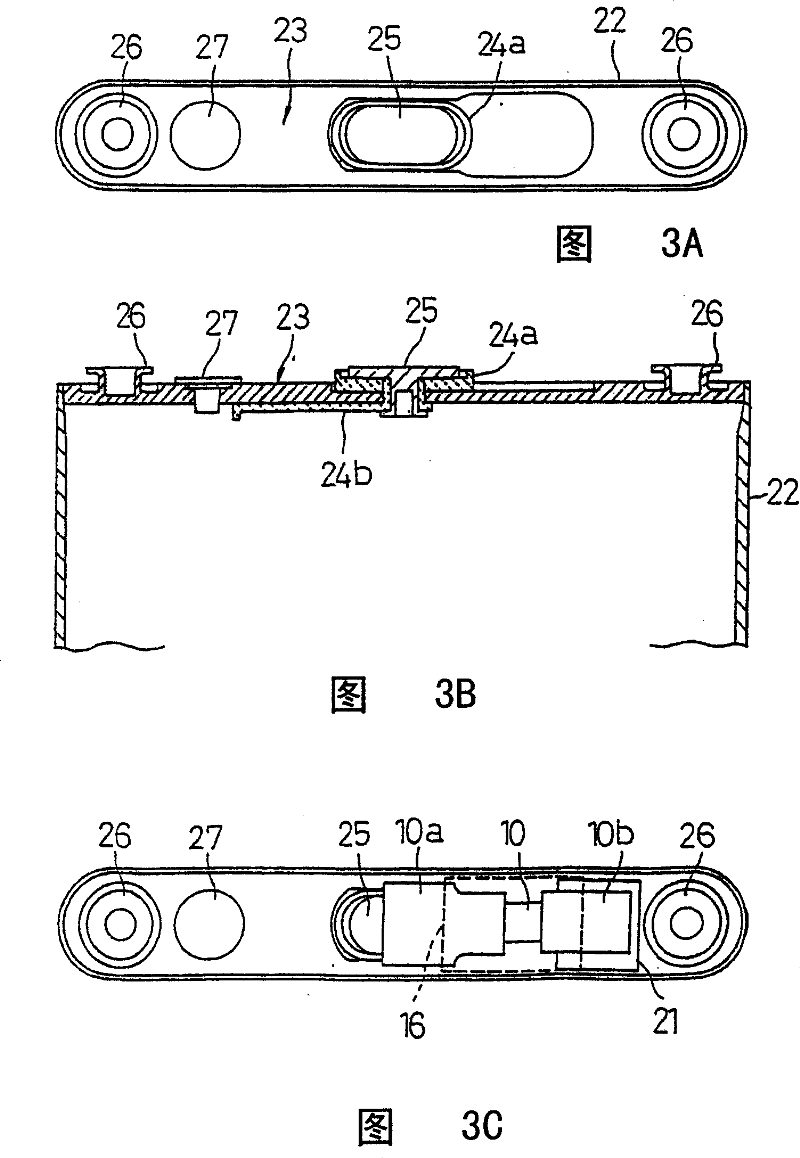

[0033] This embodiment shows an example in which a battery pack used in a mobile phone is configured using a flat prismatic lithium ion secondary battery. Battery packs for mobile phones are required to have not only small size, light weight, and thin thickness, but also high energy density suitable for high functionality, mechanical strength capable of resisting impacts such as unavoidable drops as portable devices, and a structure that is difficult to disassemble , Security function to protect the secondary battery from short circuit, overcharge and high temperature. In such a manner that these necessary conditions are satisfied, the battery pack shown below is constructed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com