Torque speed transmission

A transmission and torque technology, applied in the field of mechanical transmissions, can solve problems such as low cost and low transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

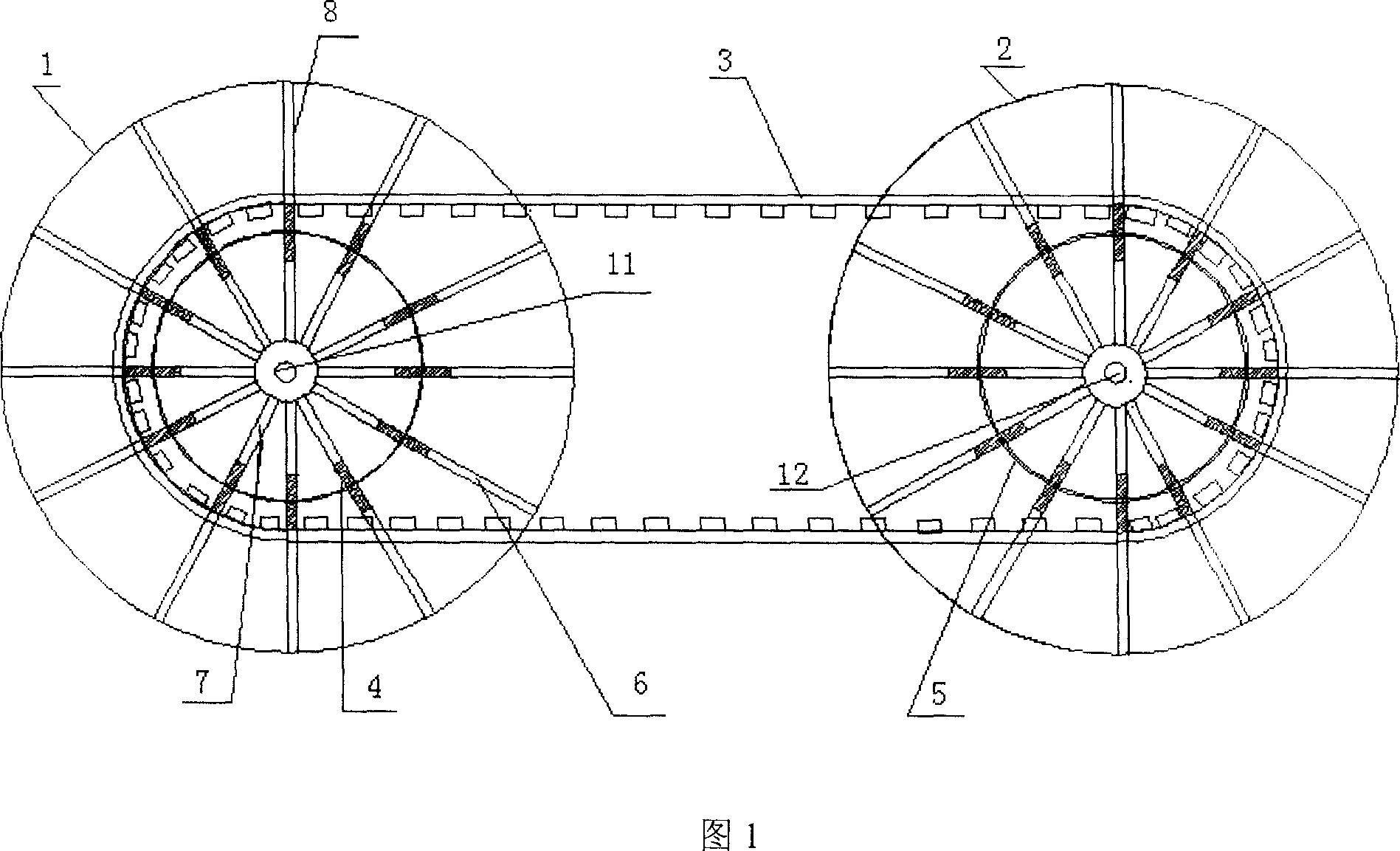

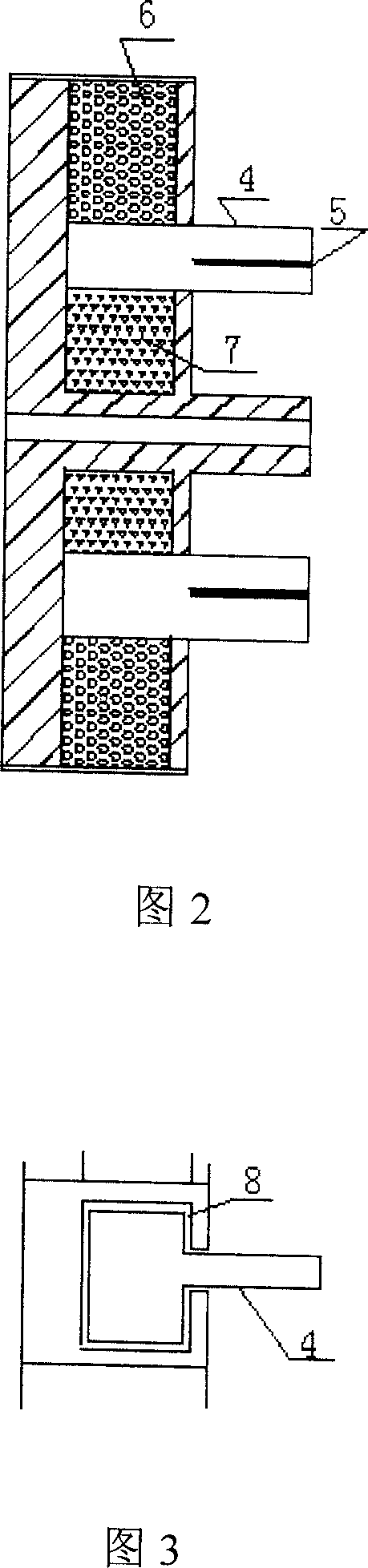

[0010] In this embodiment, 12 torque reducing teeth 4 are provided on the driving wheel 1 and the driven wheel 2, and the moment reducing teeth 4 slide in the torque reducing tooth grooves 8 on the driving wheel 1 and the driven wheel 2, and the force is stored. Mechanism tension spring 6 and compression spring 7 are radially positioned according to the magnitude of the applied force, and the coil spring 5 controls all the torque reducing teeth 4 to reduce diameter synchronously. The torque variable diameter teeth 4 on the driving wheel 1 and the driven wheel 2 are transmitted by the toothed belt 3. The tooth pitch on the toothed belt 3 is the same as the tooth pitch at the minimum tooth diameter of the torque variable diameter teeth 4. In order to facilitate the realization of stepless Or multi-stage torque transmission, the number of teeth on the toothed belt 3 is far more than the number of teeth on the torque variable diameter tooth 4, when the torque variable diameter toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com