Disc-shaped vortex air energy generator

A vortex, air energy technology, applied in arc meshing engines, engine components, machines/engines, etc., can solve problems such as low energy conversion efficiency, large torque, and low air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

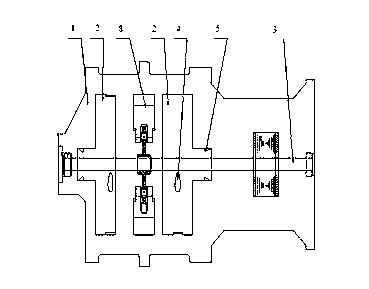

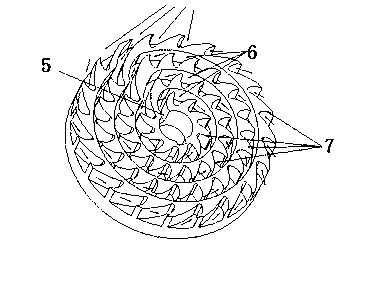

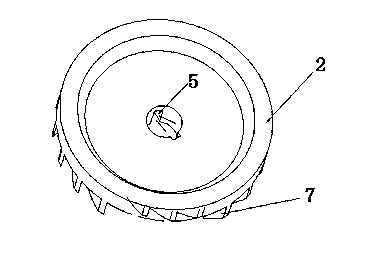

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention is a disc-shaped vortex air energy generator, including a casing 1, a rotor 2 and a rotor shaft 3, an air inlet is provided on the casing 1, and at least one rotor 2 is provided with a The air inlet hole 4 and the air outlet hole 5 corresponding to the air inlet hole, the inside of the rotor 2 is provided with a vortex-shaped air flow channel 6 connecting the rotor air inlet hole 4 and the air outlet hole 5, the air flow channel 6 has at least two layers, and The rotor body corresponding to each layer of air passages 6 is provided with damping teeth 7, and both the damping teeth 7 and the air passages 6 are parallel to the rotor shaft 3, and the wind flowing through the air passages pushes the damping teeth to rotate to drive the rotor to rotate.

[0022] The air enters the rotor from the air inlet of the casing and the rotor, enters in layers along the air flow channel in a vortex, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com