Check plate

An inspection board and inspection technology, which is applied in the field of inspection boards, can solve the problems of thermal paste 9 diffusion range damage, difficulty in correctly judging thermal paste 9 damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

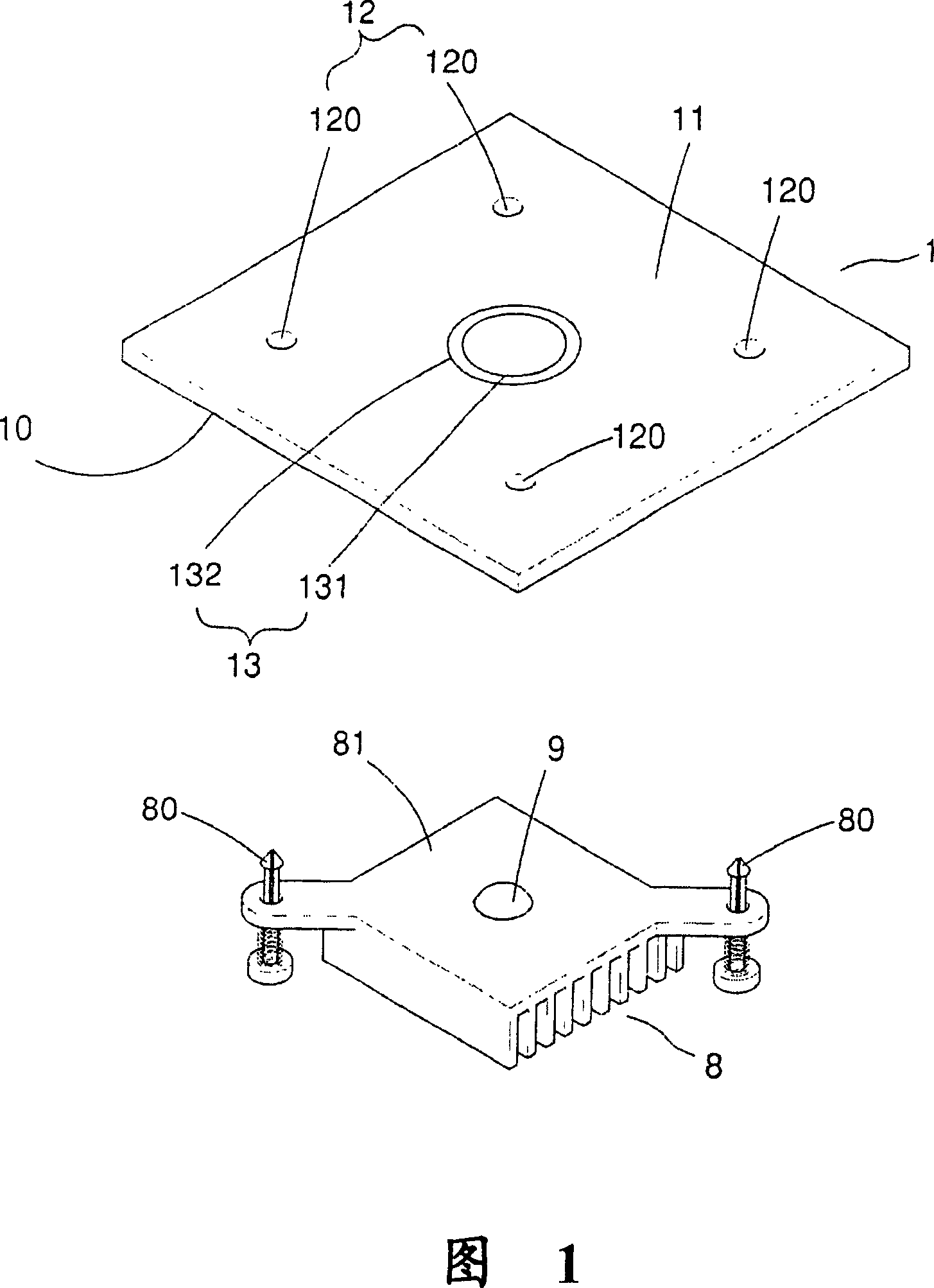

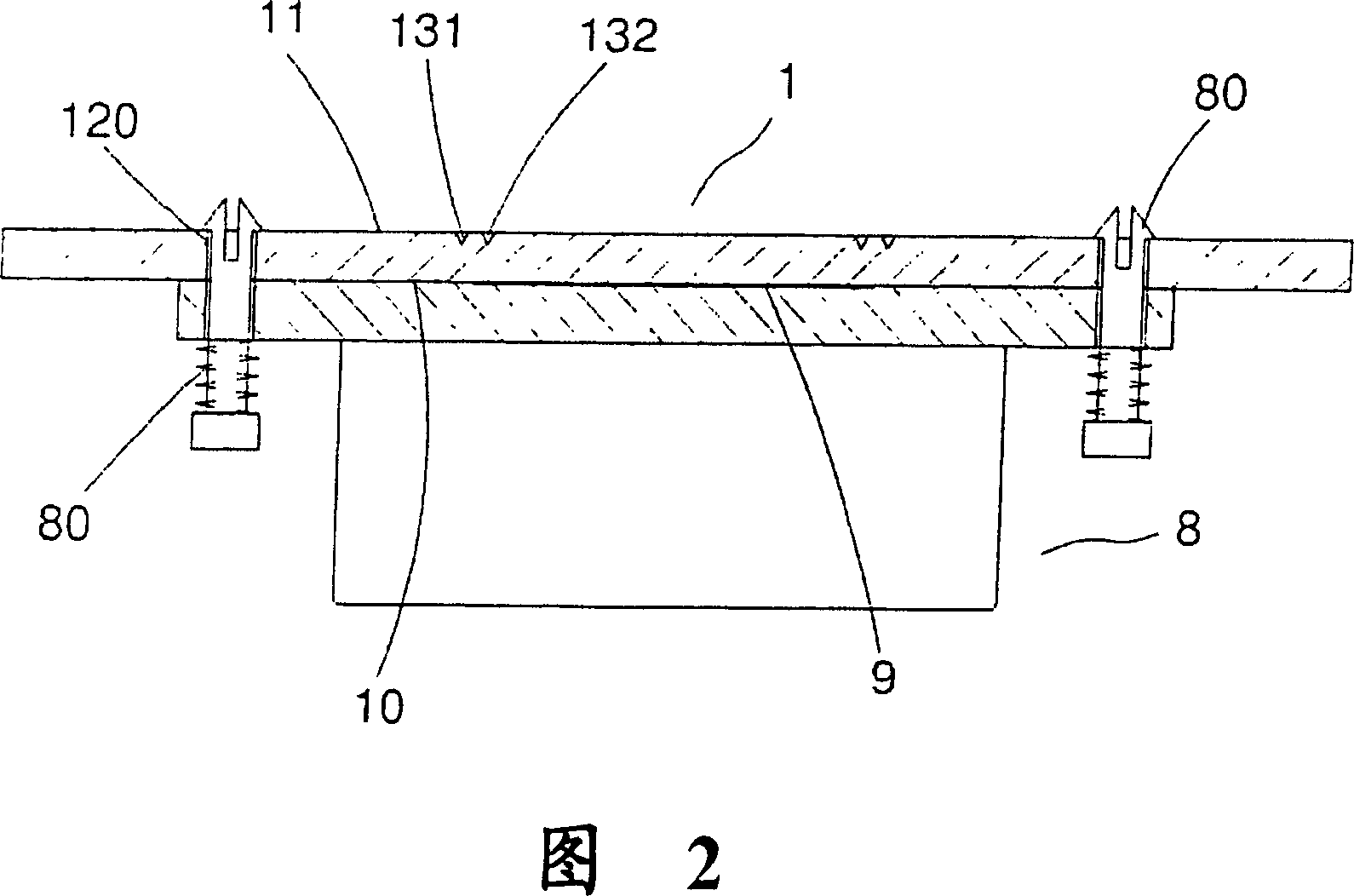

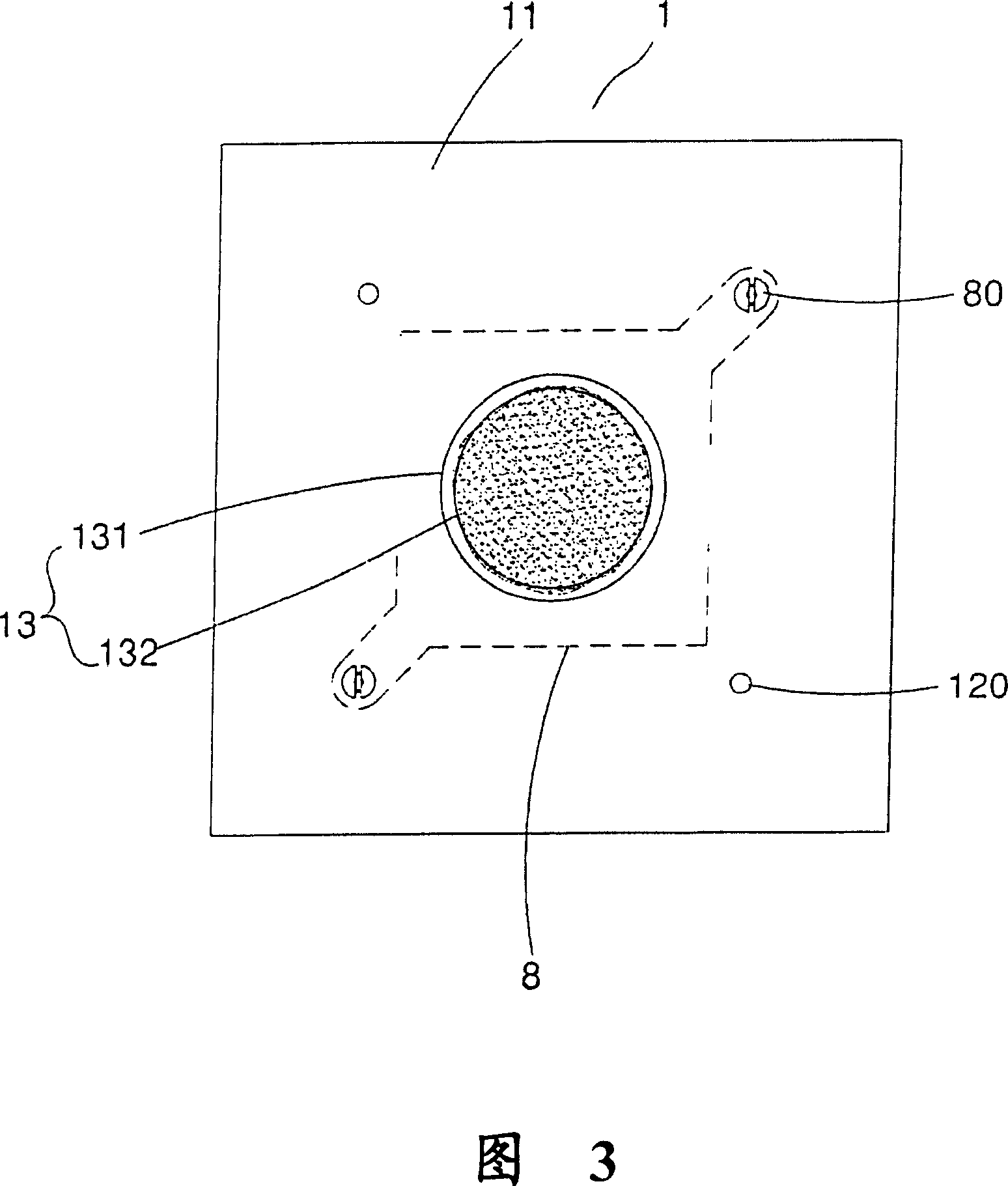

[0023] In the following description, the circuit board 7 and the heat sink 8 disclosed in FIGS. 7 and 8 will be used to illustrate how the present invention combines the heat sink 8 by simulating the circuit board 7 . However, this is only for convenience of description. In fact, the present invention can also simulate other devices, and the combined device is not limited to the heat sink 8, and the thermal conductive paste 9 can also be a paste medium with other specific functions, such as conductive glue.

[0024] The present invention is used to simulate the appearance size (such as surface profile, area and thickness, etc.) of at least a part of a first device, and the simulated part of the present invention is see-through, so it is possible to apply different heat dissipation pastes several times Get an optimal coating amount after the amount. In this way, the optimal coating amount can be applied to the actual combination production process of the first device and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com