Silicon-contained series surfur-family compound phase transformation film material for phase transformation memory

A phase-change memory and chalcogenide technology, which is applied in the field of materials in the field of microelectronics, can solve problems such as affecting the contact between phase-change films and electrodes or other film layers, affecting device stability, and detrimental device operation, and reducing write Operating current, improved life, good energy transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

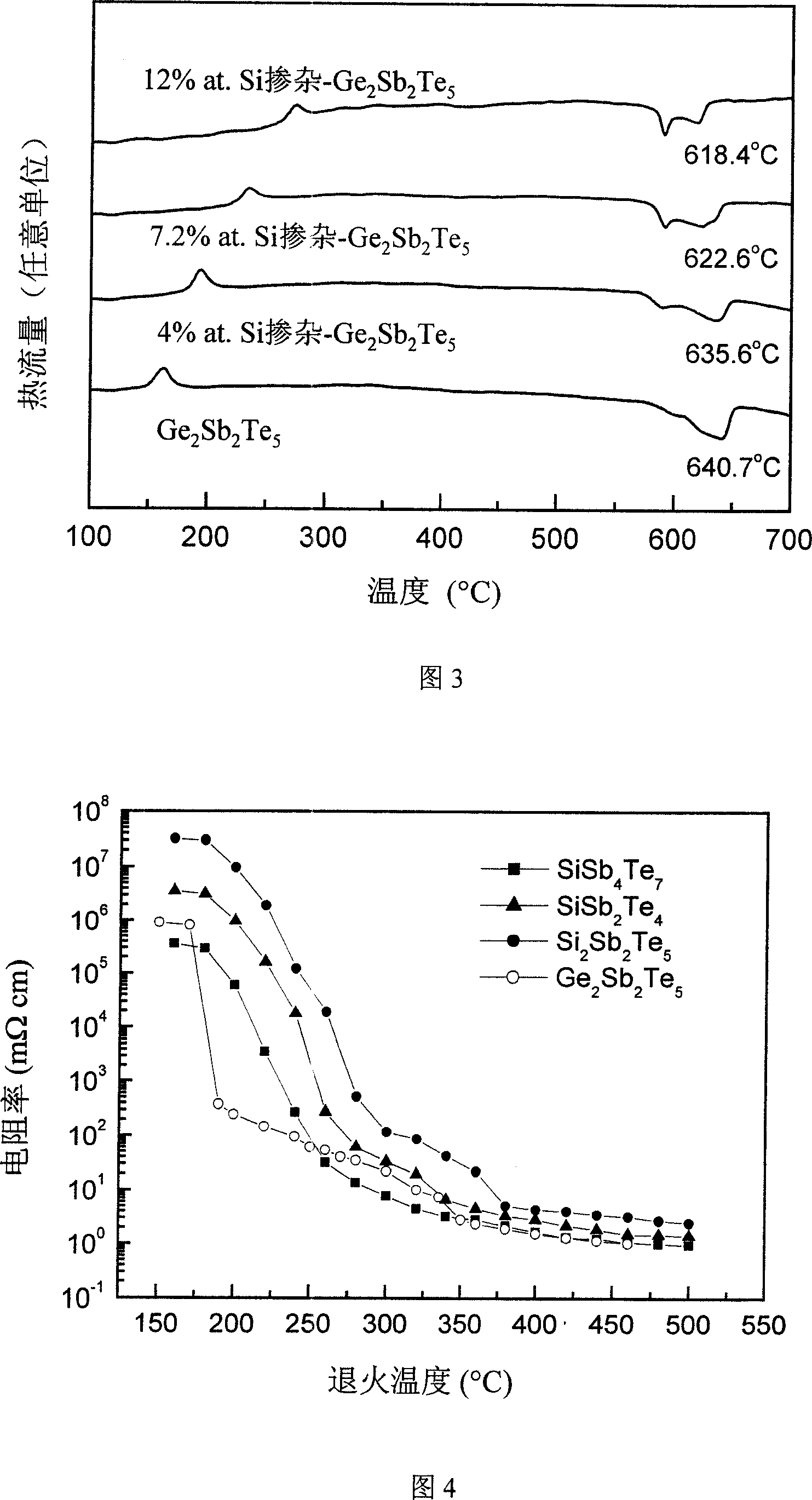

[0025] The phase change material series is Si doped into Te a Ge b Sb 100-(a+b) Alloy Si-doped Ge-Sb-Te films. The ranges of parameters a and b are proposed with reference to the parameter ranges of the patents of S.R.Ovshinsky et al. on phase change memory. Figure 2 shows Si-doped Ge obtained with different Si doping amounts 2 Sb 2 Te 5 Thin films and commonly used Ge 2 Sb 2 Te 5 The relationship between film resistivity and annealing temperature. At a temperature of 160°C and below, all films are in an amorphous state, and the film resistance is in a high resistance state. As the annealing temperature increases, the film begins to crystallize, and the film resistivity begins to decrease. When the film is crystallized, the film resistance is in a low resistance state. This process is realized in the device by heating the phase-change film with electric pulses, and the reversible transition between the high-resistance state and the low-resistance state can be achieve...

Embodiment 2

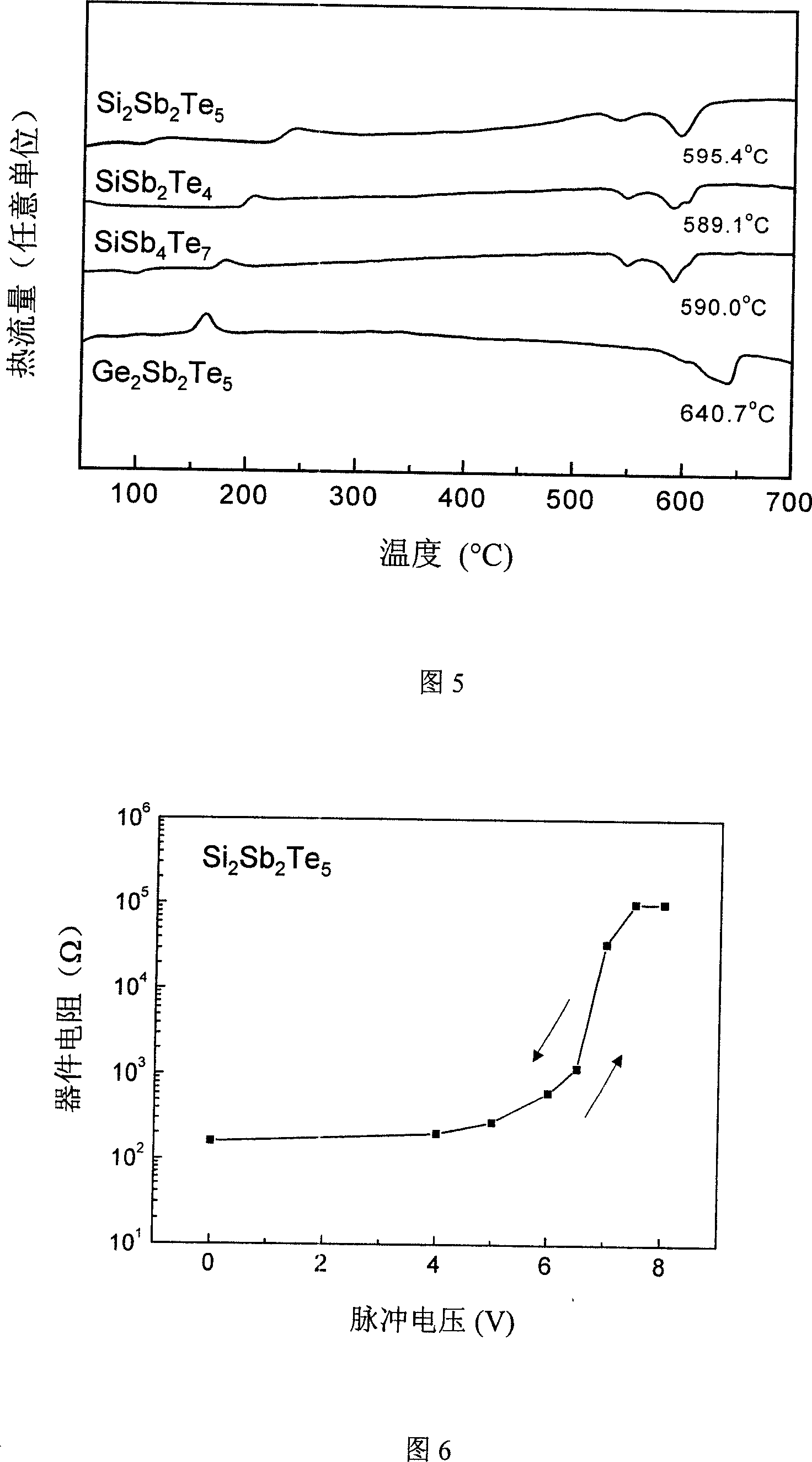

[0032] The phase change material series is a Si-Sb-Te alloy film formed by completely replacing the Ge element in the Ge-Sb-Te alloy with Si element. Fig. 4 is Si-Sb-Te chalcogenide film of the present invention and commonly used Ge 2 Sb 2 Te 5 The relationship between film resistivity and annealing temperature. At a temperature of 160°C and below, all films are in an amorphous state, and the film resistance is in a high resistance state. As the annealing temperature increases, the film begins to crystallize, and the film resistivity begins to decrease. When the film is crystallized, the film resistance is in a low resistance state. This process is realized in the device by heating the phase-change film with electric pulses, and the reversible transition between the high-resistance state and the low-resistance state can be achieved by applying different electric pulses. Si-Sb-Te alloy thin films compared with commonly used Ge 2 Sb 2 Te 5 thin film, its amorphous resisti...

Embodiment 3

[0041] Both Ge element and Si element are group IV elements and have the same valence in the alloy, so the element Si can partially or even completely replace the Ge element in the Ge-Sb-Te alloy. When the Si element completely replaces the Ge element, it forms an implementation Si-Sb-Te alloy thin films described in Example 2. Si elements partially replace Te a Ge b Sb 100-(a+b) The Ge element in the alloy can form Te a Ge b-c Si c Sb 100-(a+b) alloy film. With reference to the experimental results of Example 1 and Example 2, it can be seen that the partial replacement of Ge elements by Si elements can still achieve the following effects: (1) improve the amorphous / crystalline resistance change rate of the film, thereby improving the on / off of the device Compare. (2) At the same time, the crystalline resistance of the thin film is appropriately increased, so as to achieve the purpose of reducing the writing operation current. (3) Lower the melting point of the film. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com