Self-assembled model and preparation method thereof, and self-assembly method of light-adjustable friction coefficient film

A self-assembled film and friction coefficient technology, applied in the field of tribology, can solve problems such as irreversibility, and achieve the effect of improving cognition, wide application range and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

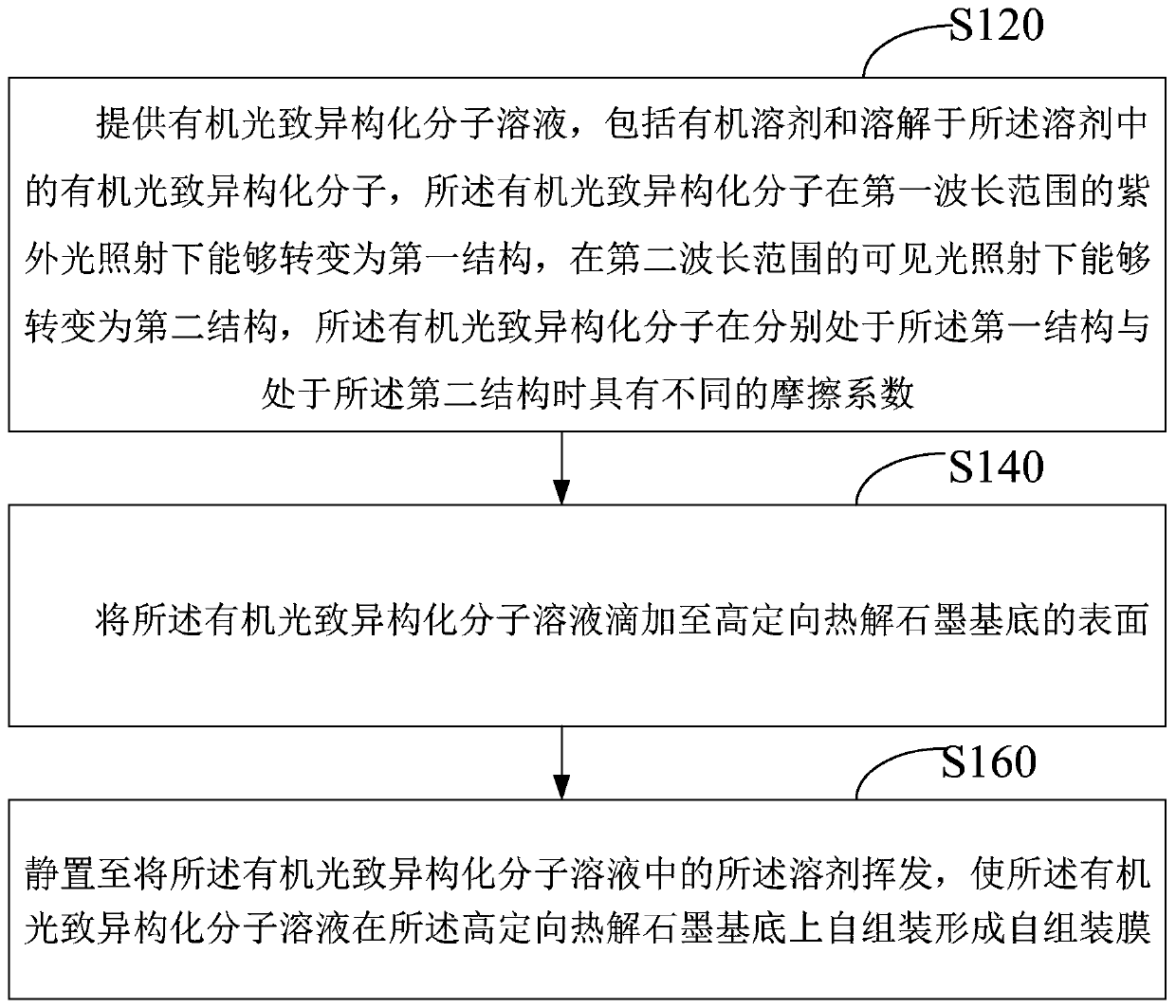

[0040] see figure 1 , an embodiment of the present invention provides a method for preparing a self-assembly model, including:

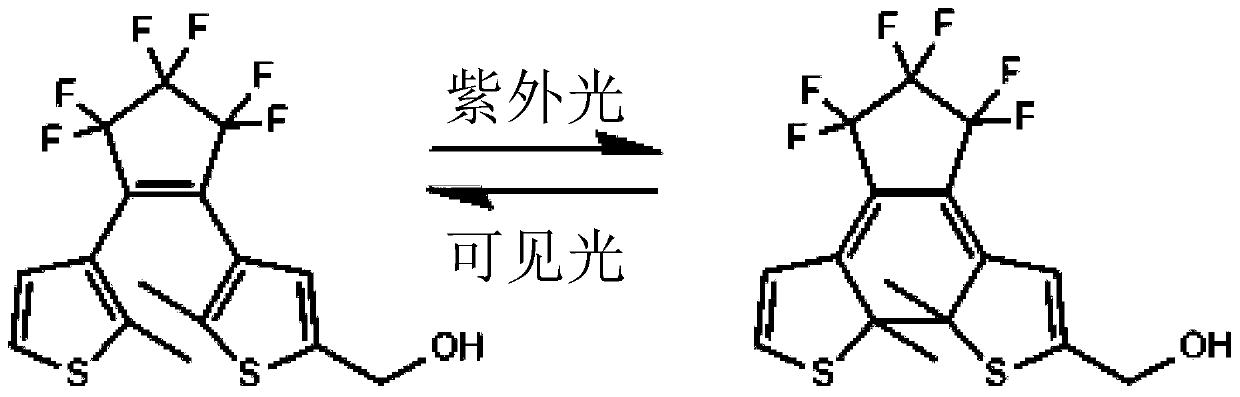

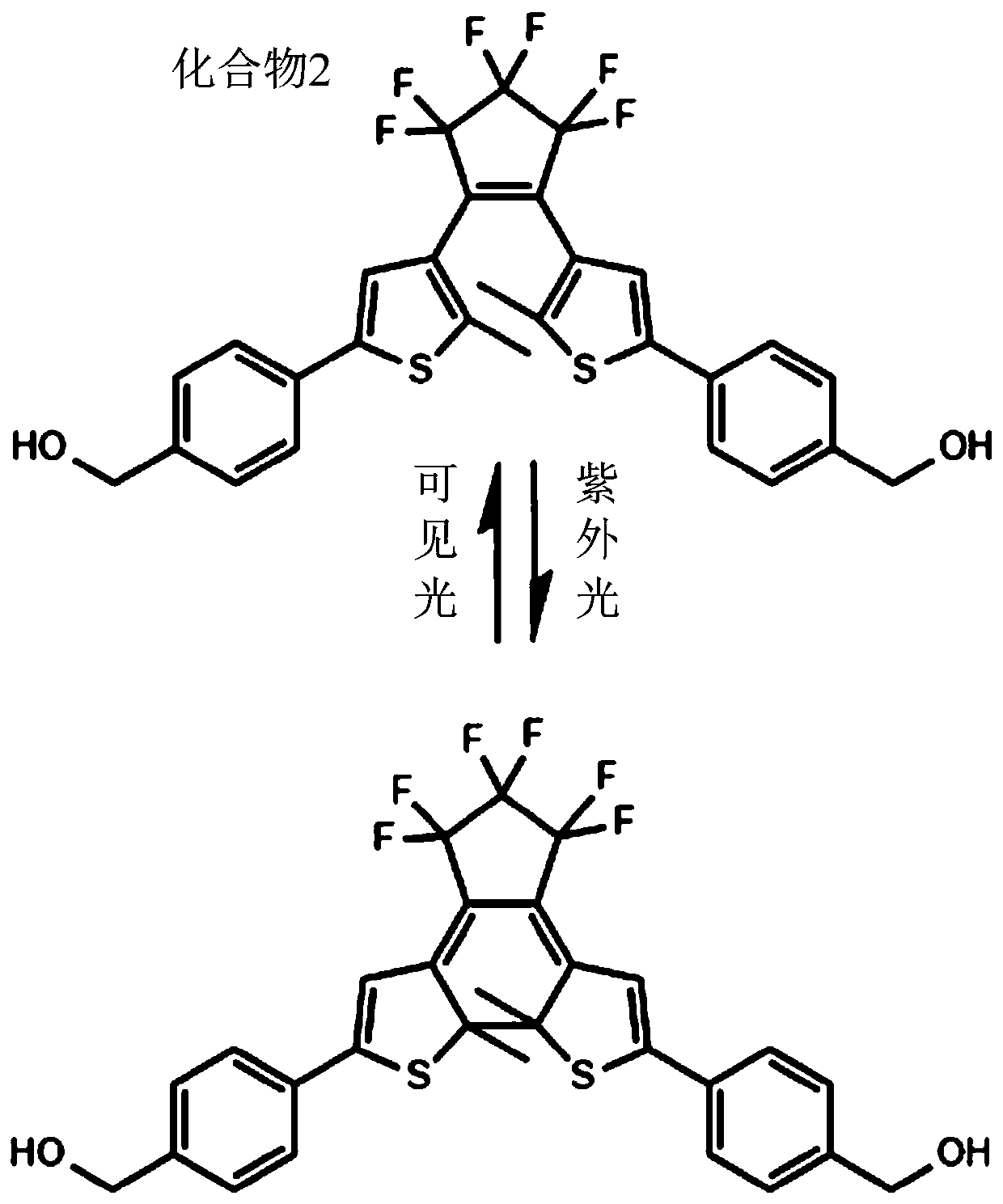

[0041] S120, providing an organic photoisomerization molecule solution, including a solvent and organic photoisomerization molecules dissolved in the solvent, the organic photoisomerization molecules can be transform into a first structure, and can transform into a second structure under the irradiation of visible light in a second wavelength range, and the organic photoisomerization molecules have different coefficient of friction;

[0042] S140, adding the organic photoisomerization molecule solution dropwise to the surface of the highly oriented pyrolytic graphite substrate; and

[0043] S160, standing still until the solvent in the organic photoisomerization molecular solution is volatilized, so that the organic photoisomerization molecular solution self-assembles on the highly oriented pyrolytic graphite substrate to form a self-assembled film...

Embodiment

[0075] (1) An organic solution of the organic photoisomerization molecule azobenzene tetracarboxylate is prepared. The solvent is heptanoic acid, and the concentration in the solution is 5×10 -5 M.

[0076] (2) Generation of self-assembled membranes. Conductive highly oriented pyrolytic graphite (HOPG) was chosen as the substrate. Use a pipette gun to take 0.1 μl of the prepared azobenzene tetracarboxylate solution on the clean and flat surface of the highly oriented pyrolytic graphite HOPG substrate. The solvent in the azobenzene tetracarboxylate solution left to stand on the substrate volatilizes, and the azobenzene tetracarboxylate forms a monomolecular self-assembled film on the substrate to prepare a self-assembly model. The intermolecular interactions are driven by non-covalent hydrogen bonds.

[0077] (3) Morphological characterization of the self-assembled film. Please refer to 10, using scanning tunneling microscope STM scanning topography to characterize the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com