Double constant currents of intelligent inversion soldering machine and self-optimizing control method

A technology of inverter welding machine and control method, which is applied to manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of inflexible parameter adjustment and control, unfavorable welding performance, and inconvenience to welders, so as to improve the dynamic performance of the power supply. , easy to operate and understand, adjust and control flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

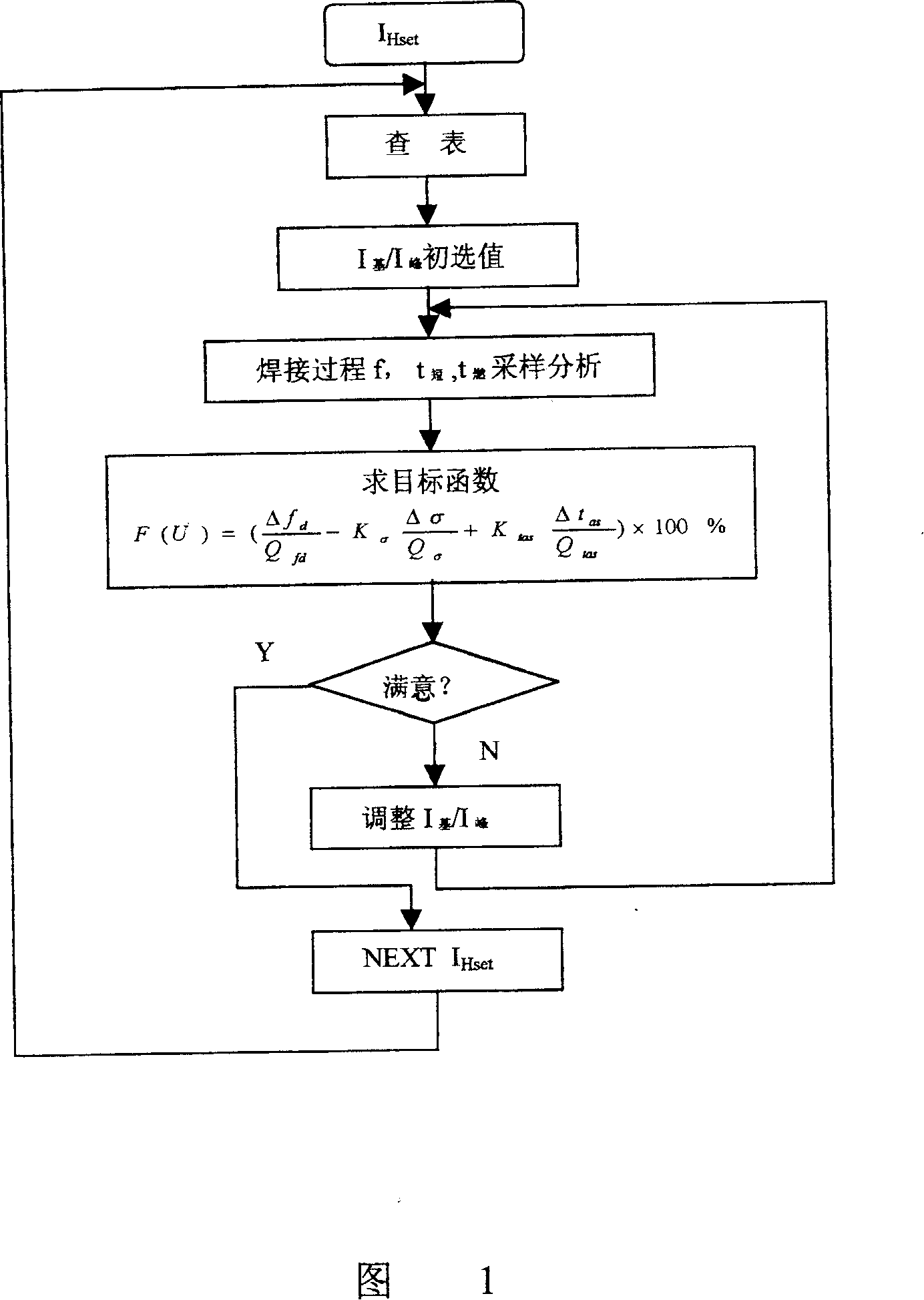

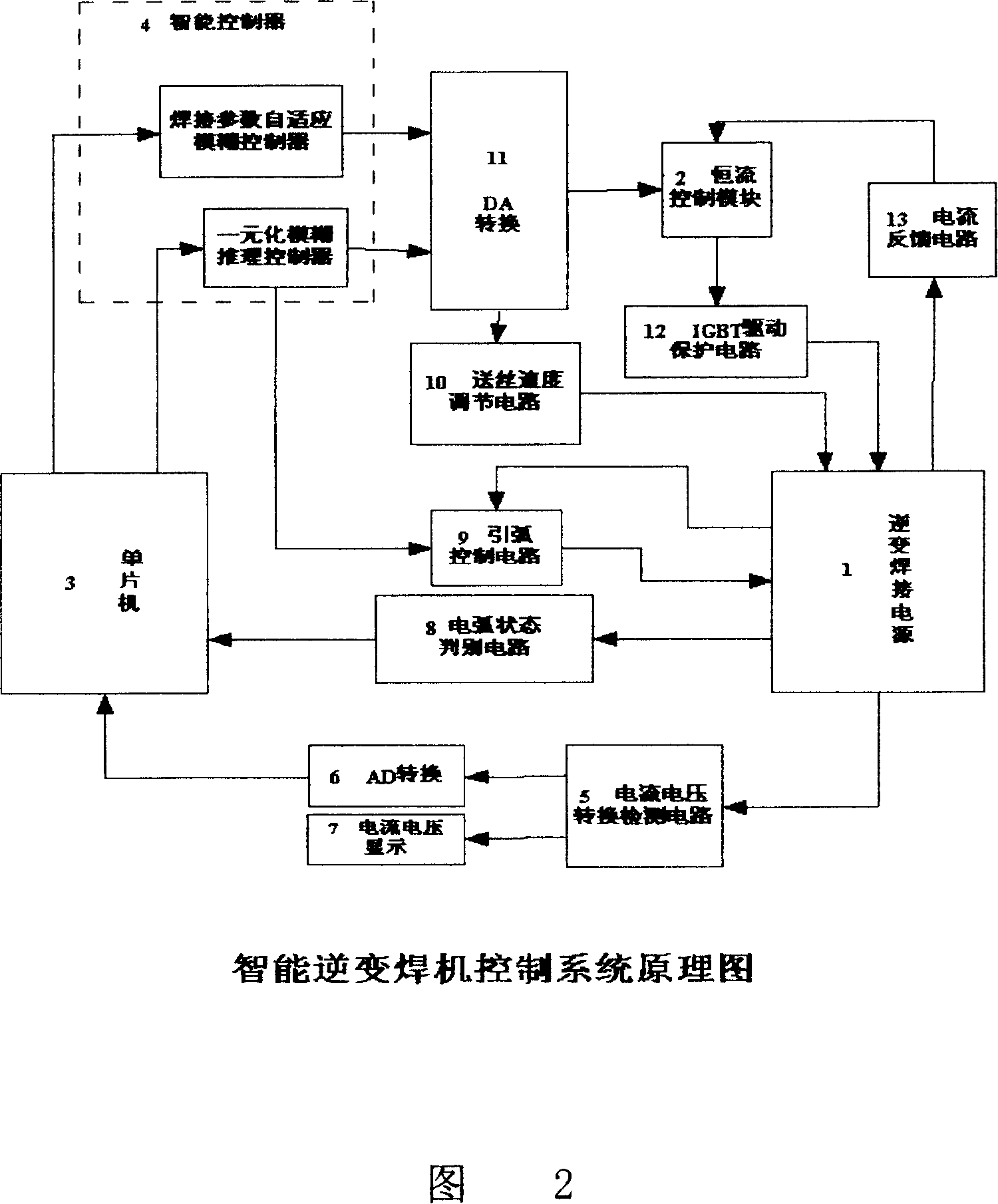

[0027] See Figure 1 and Figure 2, the working process of the smart inverter welding machine is:

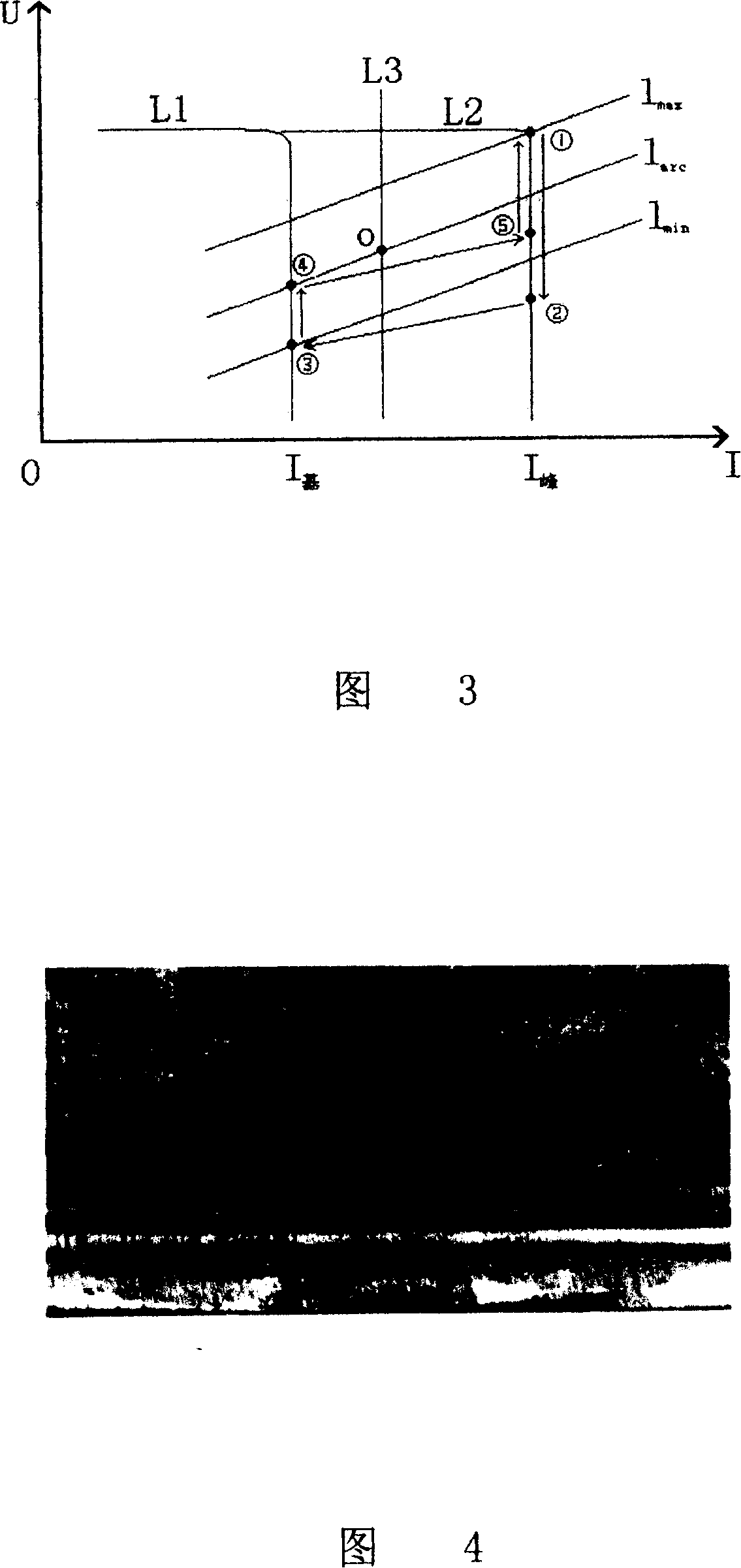

[0028] When the welding current is less than 180A-200A, the three constant current control methods of short circuit, arc peak value and base value are adopted. At the beginning, add a certain base value current that matches the wire feeding speed, so that a spherical droplet 1.2 times the diameter of the welding wire is maintained at the end of the welding wire and the diameter of the droplet is controlled to prevent the arc from being unstable if the droplet diameter is too small. Splash occurs. When the droplet just touches the molten pool, the welding current is lowered to a very low level within 0.8ms to reduce the energy of the short-circuit bridge. After the bridge is formed, the current is controlled to rise to a larger current value to make the bridge Necking under a greater pressure (electromagnetic contraction force, gravity, etc.). Necking makes the current flow area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com