Rotating mechanism of video disk machine with liquid crystal display screen

A technology of liquid crystal display screen and rotating mechanism, which is applied to record carrier structural parts, the layout of structural parts in carrier equipment, instruments, etc., can solve problems such as large area and viewing effect interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

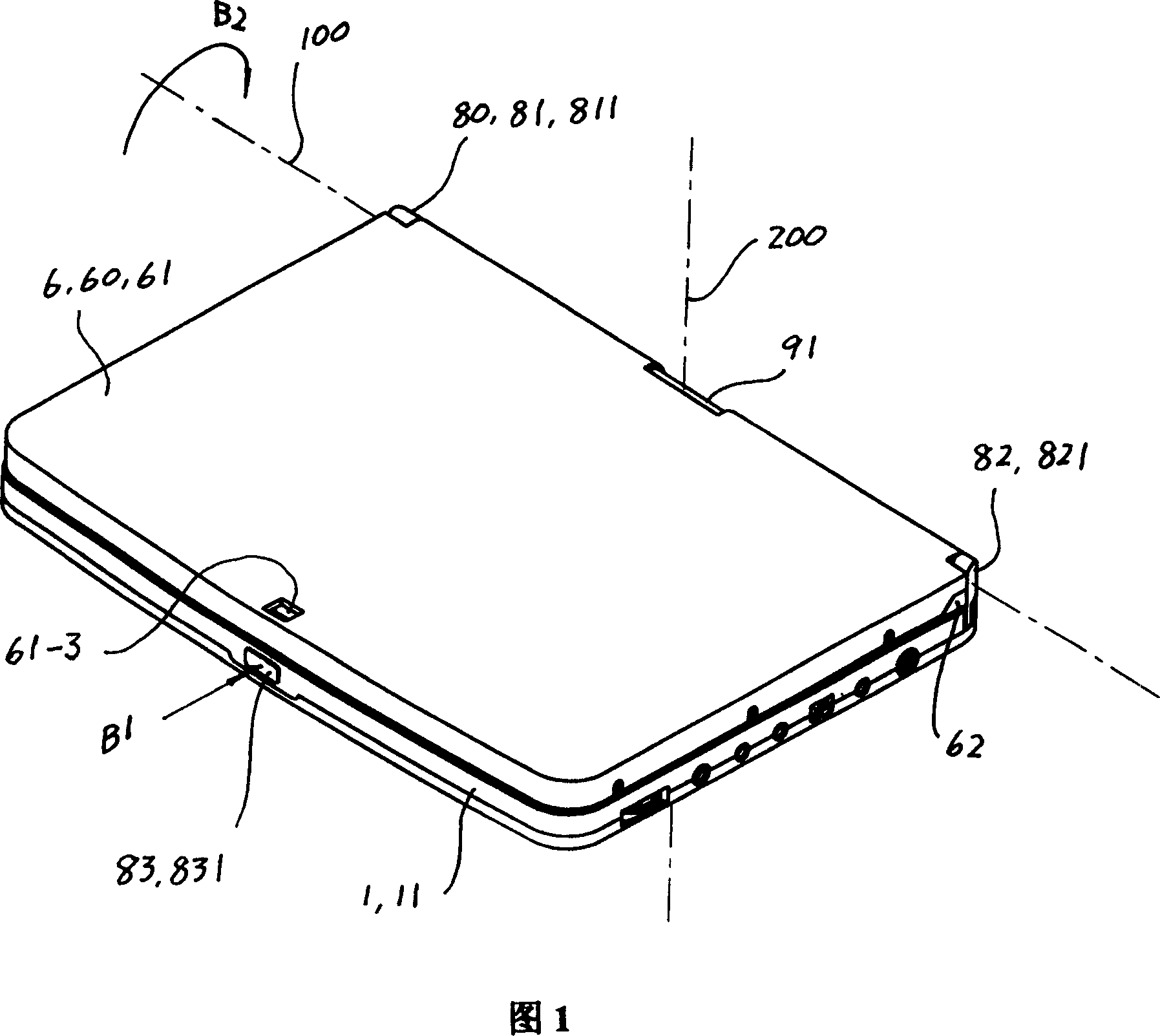

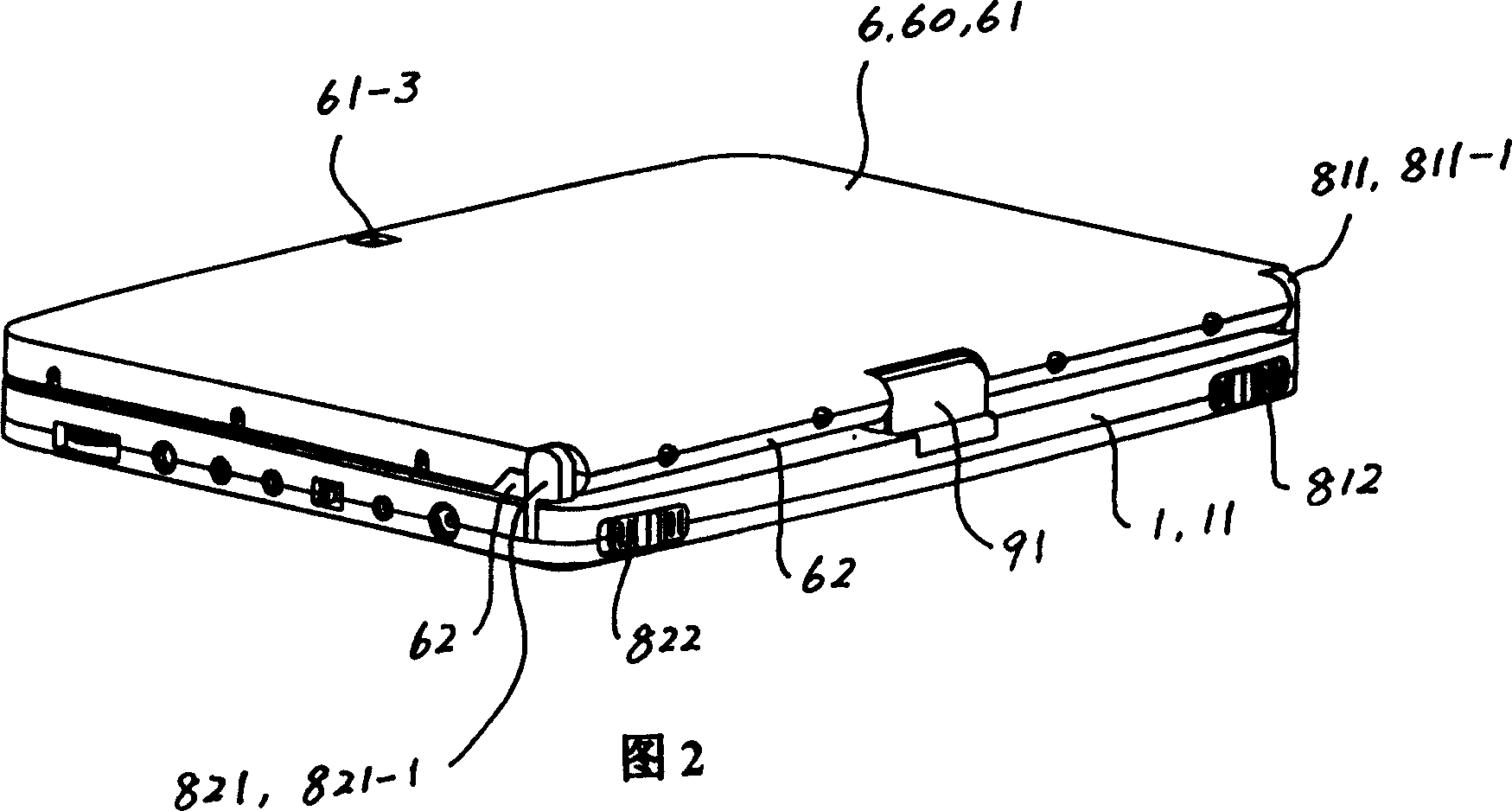

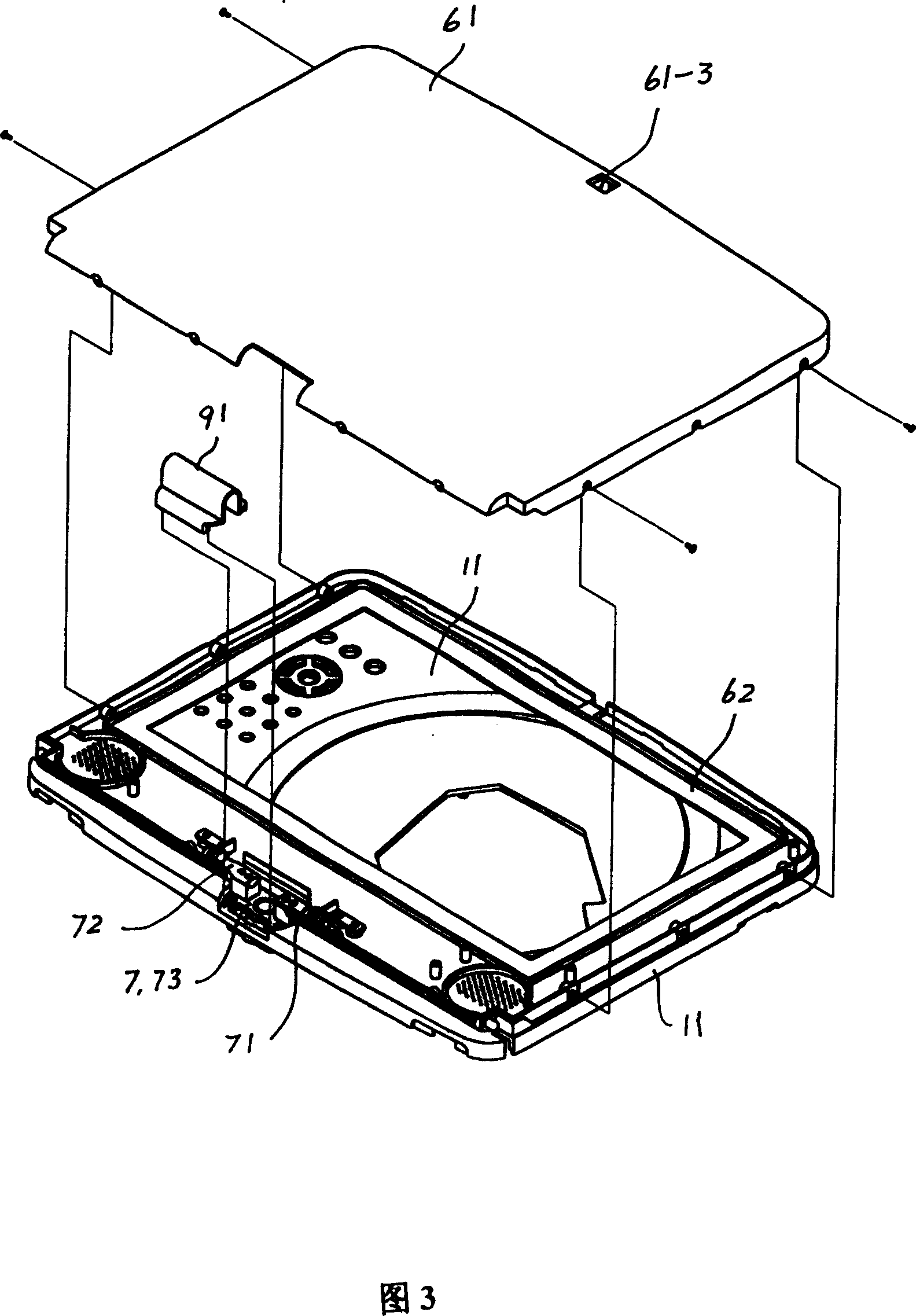

[0068] Referring to FIG. 1 to FIG. 4 , the dual-axis rotating mechanism of this embodiment has an upper seat 11 of the main machine casing, an auxiliary machine casing 60 , a rotating part 7 and a decorative cover 91 . The auxiliary machine casing 60 has a surface cover 61 and a screen cover 62 , and the surface cover 61 is fixed on the screen cover 62 to form the auxiliary machine casing 60 . The rotating part 7 is a two-axis rotating part with resistance, and the auxiliary machine casing 60 is connected with the upper seat 11 of the main casing through the rotating part 7 in a two-way direction with resistance. The decorative cover 91 is fixed with the rotating part 7 . The upper seat 11 of the main machine casing, the screen cover 62 and the decorative cover 91 of the auxiliary machine casing 60 are all plastic integral parts, the face cover 61 of the auxiliary machine casing 60 is an aluminum plate punching part, and each part in the rotating part 7 is steel parts.

[00...

Embodiment 2

[0100] See Figures 47 to 50 and Figures 1 to 4, the rotating mechanism of this embodiment is still a two-axis rotating mechanism, and the rest of the rotating mechanism is the same as that of Embodiment 1, except that the rotating parts of this embodiment 7 is structurally different from the rotating part 7 in Embodiment 1. 51 to 54, the first moving shaft rotating assembly 71 of the rotating part 7 in this embodiment has a first connecting arm 711, a first inner friction washer 712, a first rotating foot 713, a first outer friction washer 714, a first Elastic washer 715 , first outer stop washer 716 and first lock nut 717 . The second moving shaft rotating assembly 72 of the rotating part 7 in this embodiment has a second connecting arm 721, a second inner friction washer 722, a second rotating foot 723, a second outer friction washer 724, a second elastic washer 725, a second outer Stop washer 726 and second lock nut 727.

[0101] Still referring to FIG. 51 to FIG. 54 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com