Method for preparing shortening oil emulsifier

A technology of emulsifier and shortening, which is applied in dough processing, edible oil/fat, baking, etc., and can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation method of separate emulsifier

[0042] Get the ratio of emulsifier and shortening as 1: 4, prepare separate emulsifier (DGMS, PGMS, SSL, PS-60 and SMS).

[0043] Loaf Cake Recipe

[0044] G

[0045] Wheat Flour 100

[0046] Granulated sugar 90-110

[0047] Egg 115-125

[0048] Shortening 62-70

[0049] Calcium propionate 0.3-0.5

[0050] Baking powder 0.3-0.5

[0051] Salt 0.3-0.5

[0052] Acetic acid 0.1-0.25

[0053] water 5-15ml

[0054] essence

[0055] Lemon 2-2.5ml

[0056] Vanilla 2-2.5ml

[0057] Emulsifier / developed emulsifier formulation 2-3 / 4-6

[0058] - sift calcium propionate, baking powder and salt with flour;

[0059] - Mix the fat with the flour in a mixer at speed III for 5 minutes;

[0060] - Whisk eggs, sugar and emulsifier / developed emulsifier formula at speed III for 5-6 minutes;

[0061] - transfer the egg mixture in 3 parts to the fat-flour mixture while mixing on speed I for 3 minutes until smooth;

...

Embodiment 1

[0094] Loaf Cake Recipe

[0095] G

[0096] Wheat Flour 100

[0097] Granulated sugar 100

[0098] egg 120

[0099] Shortening 66

[0100] Calcium propionate 0.5

[0101] Baking powder 0.5

[0102] Salt 0.5

[0103] Acetic acid 0.2

[0104] water 10

[0105] essence

[0106] Lemon 2.5ml

[0107] Vanilla 2.5ml

[0108] - sift calcium propionate, baking powder and salt with flour;

[0109]- Mix the fat with the flour in a mixer at speed III for 5 minutes;

[0110] - Whisk eggs, sugar and emulsifier / developed emulsifier formula at speed III for 5-6 minutes;

[0111] - transfer the egg mixture in 3 parts to the fat-flour mixture while mixing on speed I for 3 minutes until smooth;

[0112] -Finally add essence, water and acetic acid and mix for 1 minute at speed I;

[0113] -Weigh 425g of batter and bake the cake at 180°C for 1 hour.

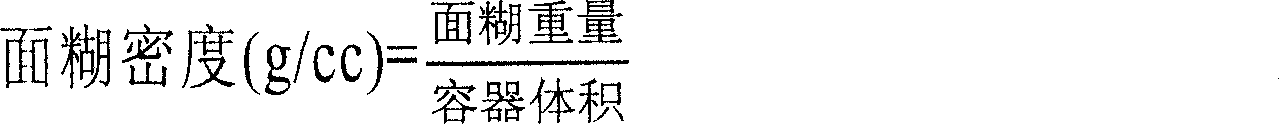

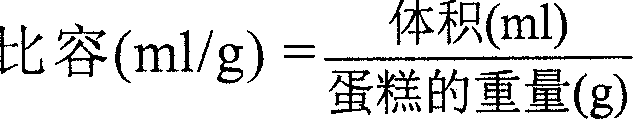

[0114] The physical characteristics of the cake were as follows: cake weight 375.10 g; volume 1200 cc; specific volume...

Embodiment 2

[0116] Loaf Cake Recipe

[0117] g

[0118] Wheat Flour 100

[0119] Granulated sugar 100

[0120] egg 120

[0121] Shortening 66

[0122] Calcium propionate 0.5

[0123] Baking powder 0.5

[0124] Salt 0.5

[0125] Acetic acid 0.2

[0126] water 10

[0127] essence

[0128] Lemon 2.5ml

[0129] Vanilla 2.5ml

[0130] Emulsifier (DGMS) 2.5

[0131] - sift calcium propionate, baking powder and salt with flour;

[0132] - Mix the fat with the flour in a mixer at speed III for 5 minutes;

[0133] - Whisk eggs, sugar and emulsifier / developed emulsifier formula at speed III for 5-6 minutes;

[0134] - transfer the egg mixture in 3 parts to the fat-flour mixture while mixing on speed I for 3 minutes until smooth;

[0135] -Finally add essence, water and acetic acid and mix for 1 minute at speed I;

[0136] -Weigh 425g of batter and bake the cake at 180°C for 1 hour.

[0137] The physical properties of the cake are as follows: cake weight 375.50g; vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com