Node type filtration irrigation pipe perforating mechanism

A technology of seepage irrigation pipes and joints, applied in metal processing, etc., can solve the problems of complex production process of seepage irrigation pipes, low irrigation uniformity, high product price, etc., and achieve the effect of simple installation, simple equipment structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

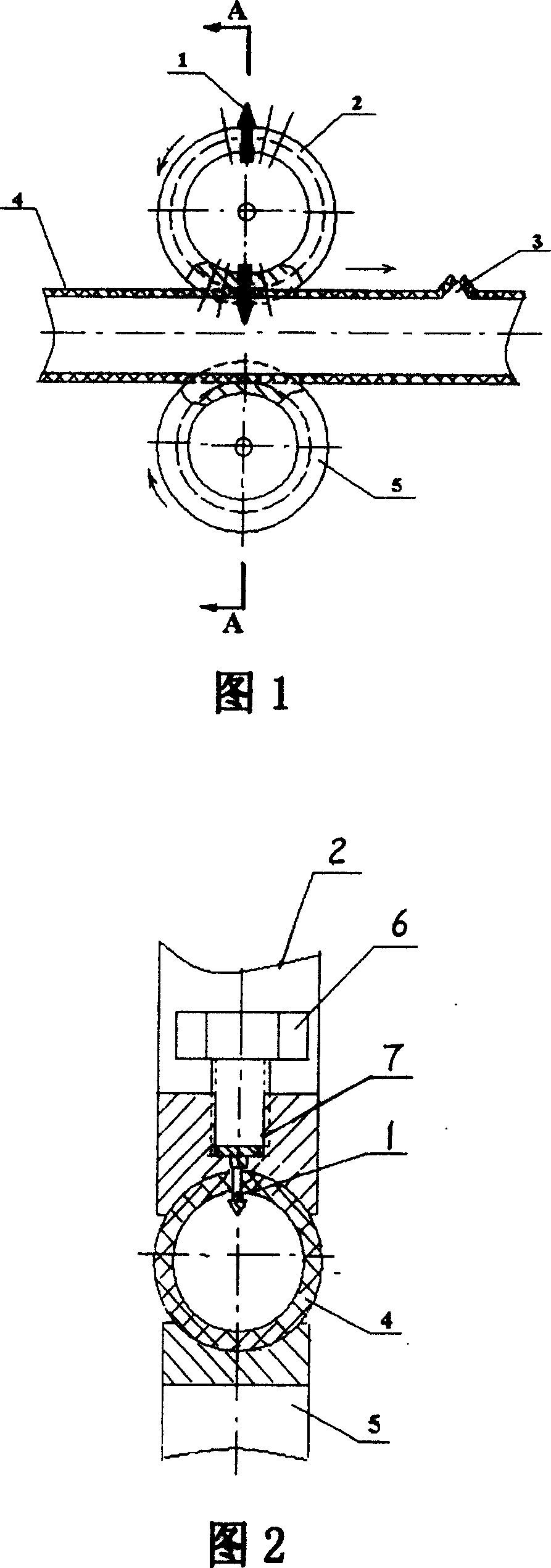

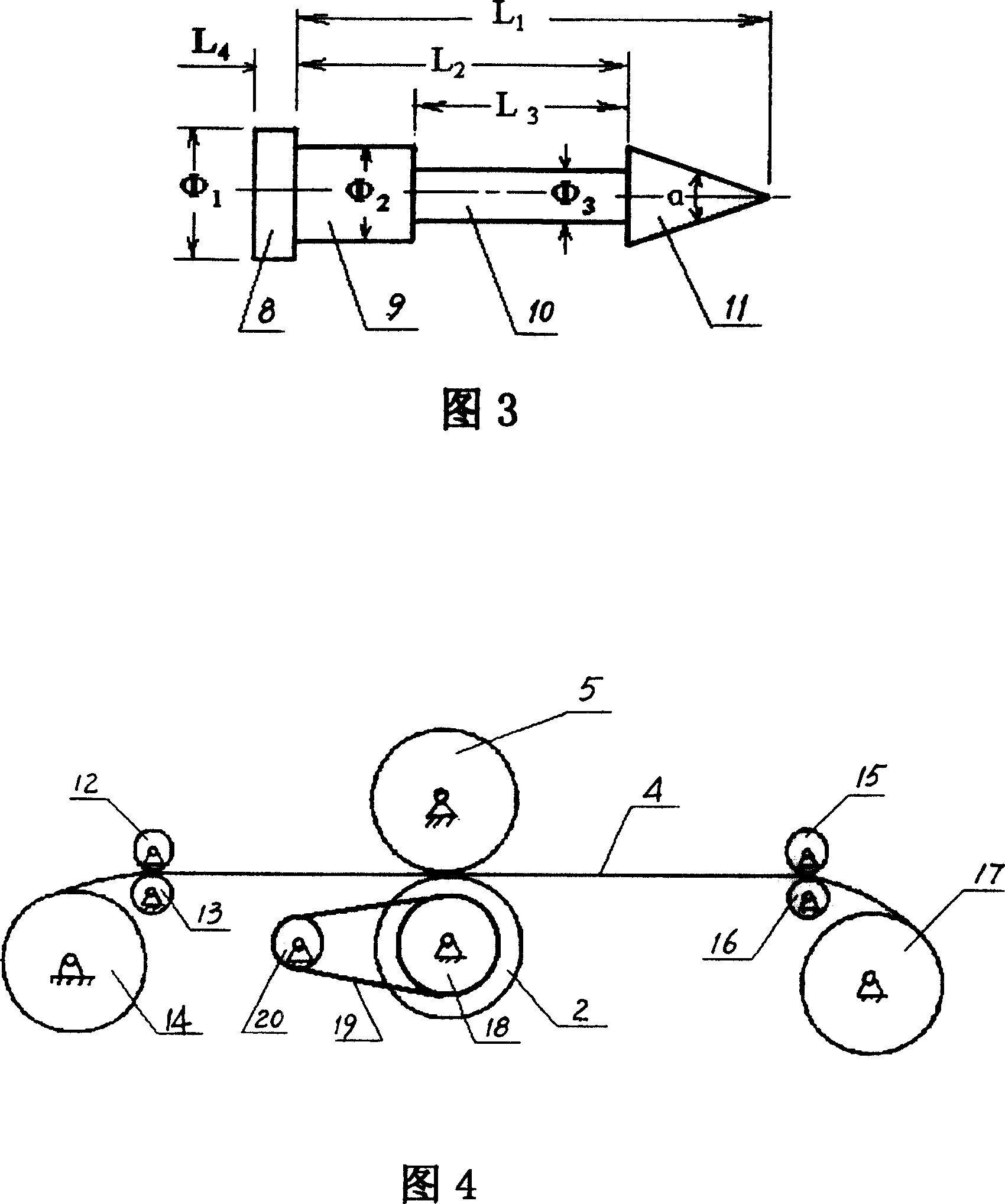

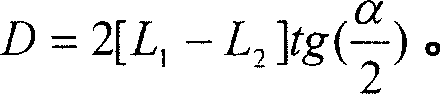

[0014] See Fig. 1, 2, 3, the perforating mechanism of percolating irrigation pipe of the present invention is mainly provided with the roller 2 and the opposite wheel 5 that are installed on the frame, and the outer periphery of the roller 2 and the opposite wheel 5 is provided with arc-shaped grooves, So that the seepage irrigation pipe 4 that passes between the two wheels fits with it. A plurality of stepped holes 7 are evenly distributed on the outer edge of the roller 2, and the front end of the umbrella-shaped punching part 1 is provided with a punching cone 11, and the rear end of the punching cone 11 is connected with a punching cylinder 10. The body 10 is connected to the axially fixed cylinder 9, and the rear end is a radially fixed cylinder 8. Diameter is φ 2 The outer cylindrical surface of the axially fixed cylinder 9 is used to cooperate with the corresponding position of the roller 1 to do the axial fixation of the umbrella-shaped punching part; the diameter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com