Processing method of rubber nut

A processing method and nut technology, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of joint wear, plastic parts assembly crushing, plastic parts damage, etc., to achieve convenient operation and protection of the connected parts , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

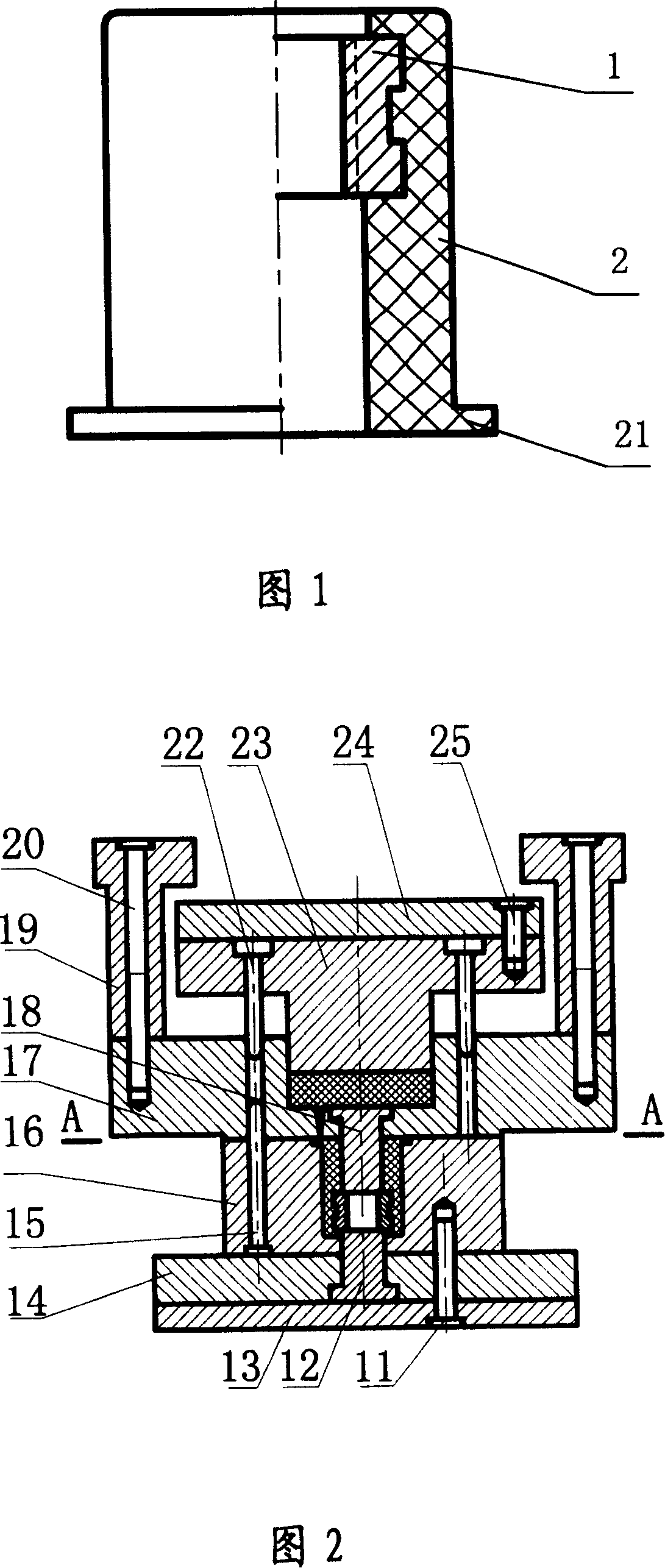

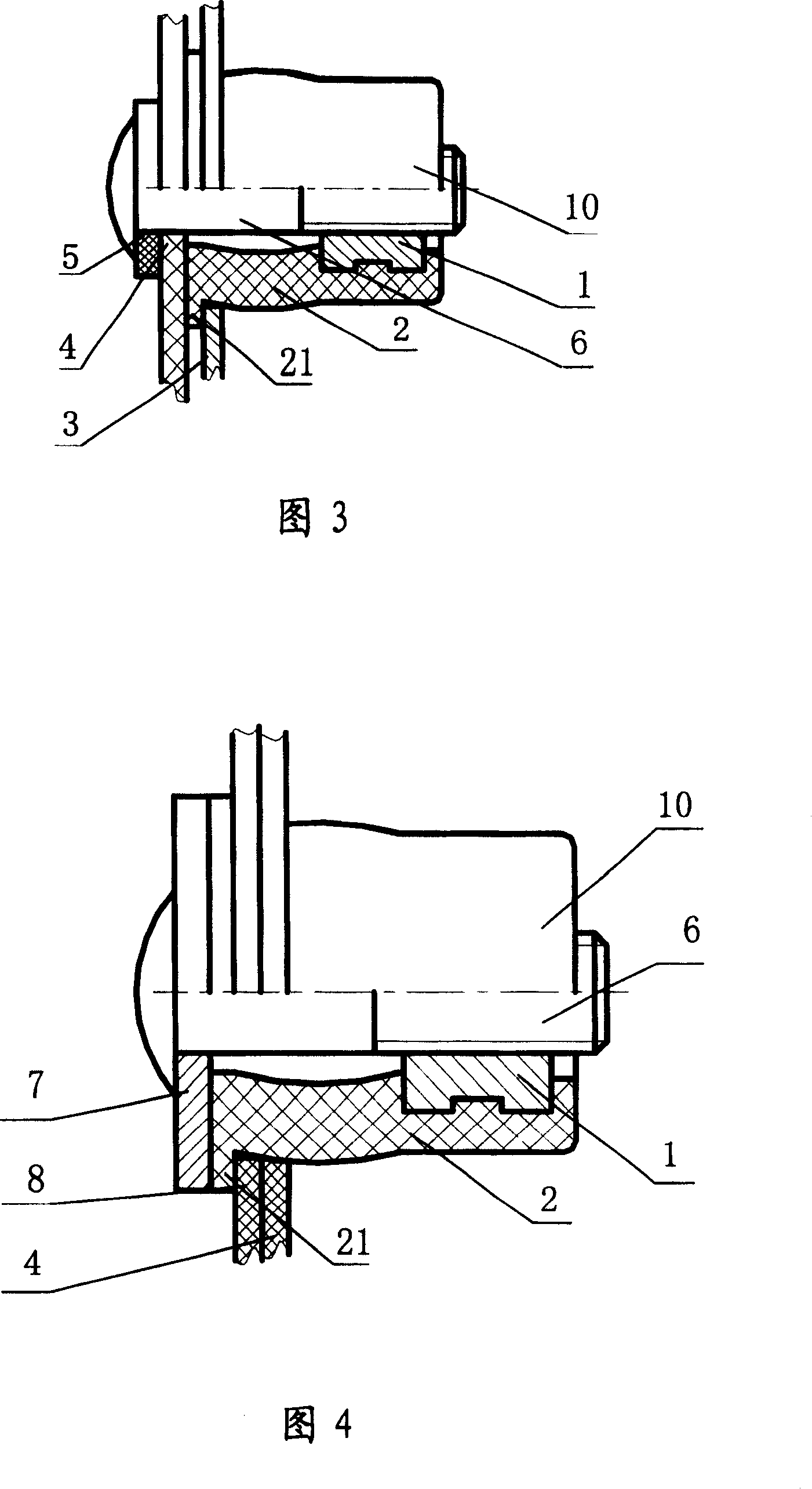

[0021] Referring to FIG. 1 , it is a structural diagram of the rubber nut according to an embodiment of the present invention. The rubber nut includes a brass nut 1 with an I-shaped shaft section and a hollow cylindrical rubber buffer 2 with two ends open. The brass nut 1 is coaxially embedded in the rubber buffer 2, the rubber buffer 2 is integrated with the brass nut 1, and the thread outer diameter of the nut is smaller than the inner diameter of the rubber buffer. One end of the rubber buffer 2 is the connecting end for connecting other parts, and the other end is the fastening end for connecting the bolt and the nut. In order to connect the two parts, the rubber buffer 2 can be firmly clamped on the parts to be connected. On the other hand, the distance between the connecting end and the fastening end is not less than 5mm, that is, the length of the deformation part of the rubber buffer is not less than 5mm; and, at the connecting end far away from the brass nut 1, there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com