High pressure valve

A high-pressure valve and valve body technology, which is applied in the direction of sliding valves, valve devices, engine components, etc., can solve problems affecting valve sealing performance, cavitation or abrasion, and seal failure, so as to increase the failure rate, reduce maintenance costs, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

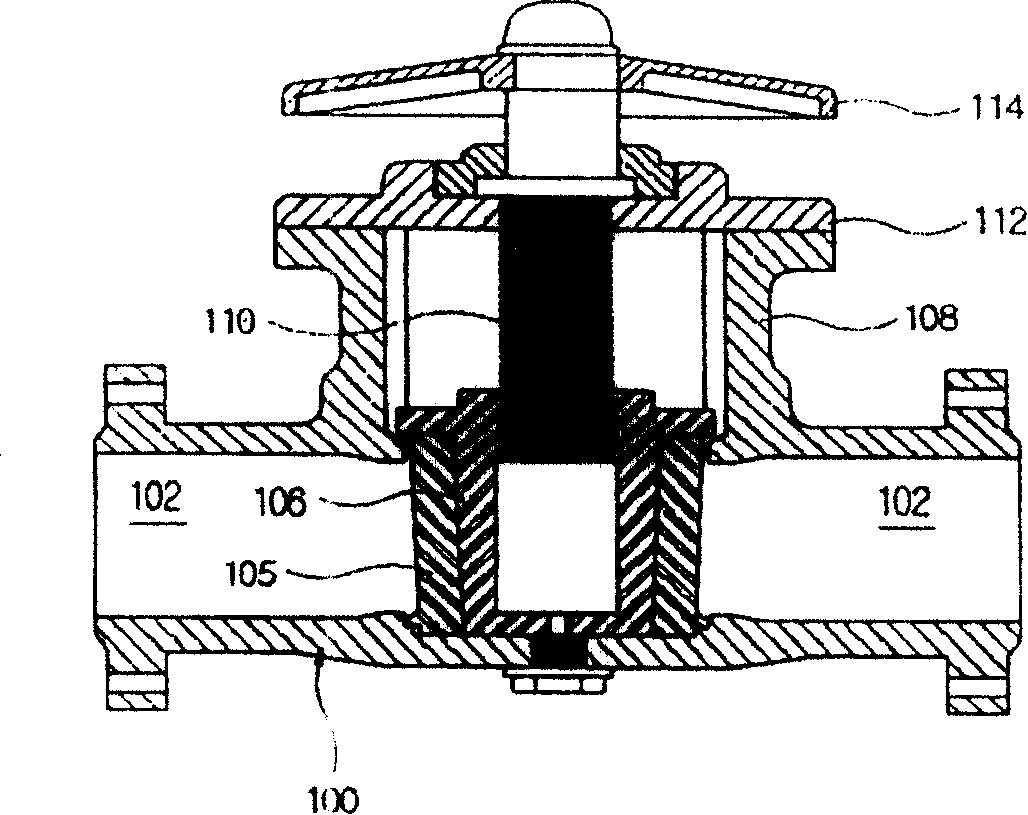

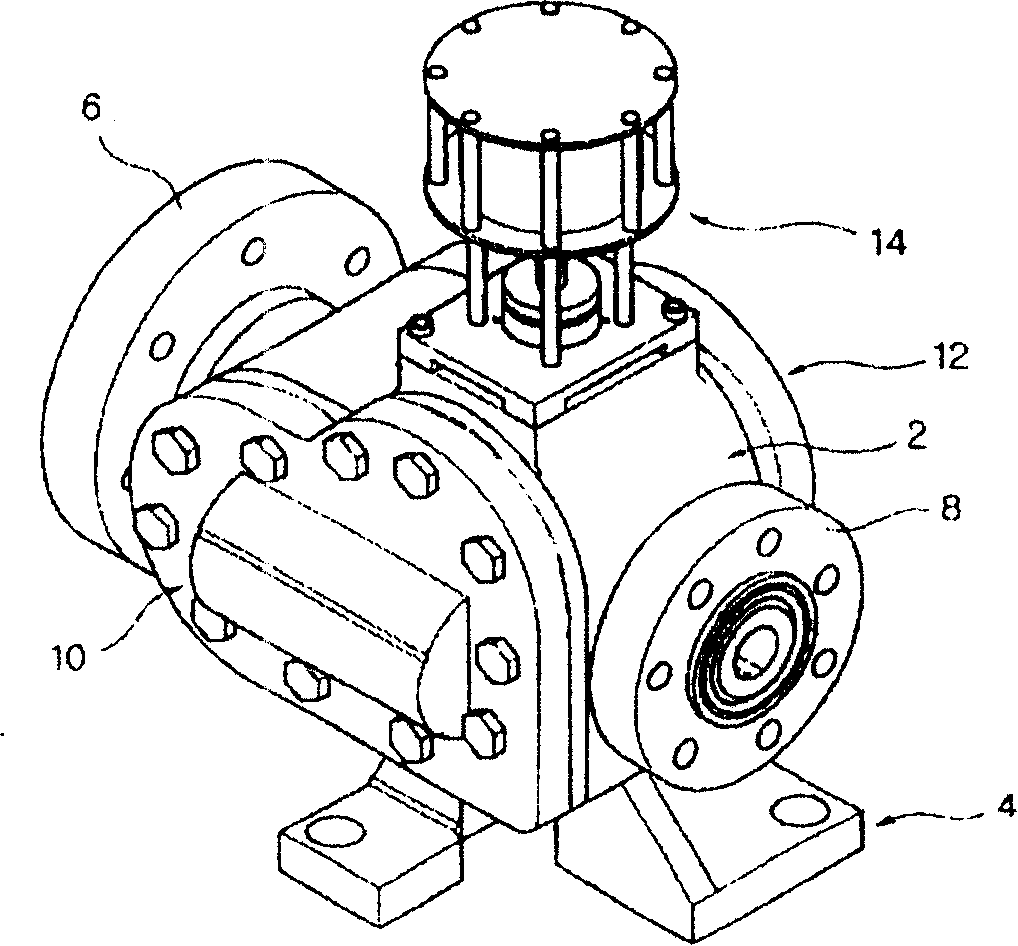

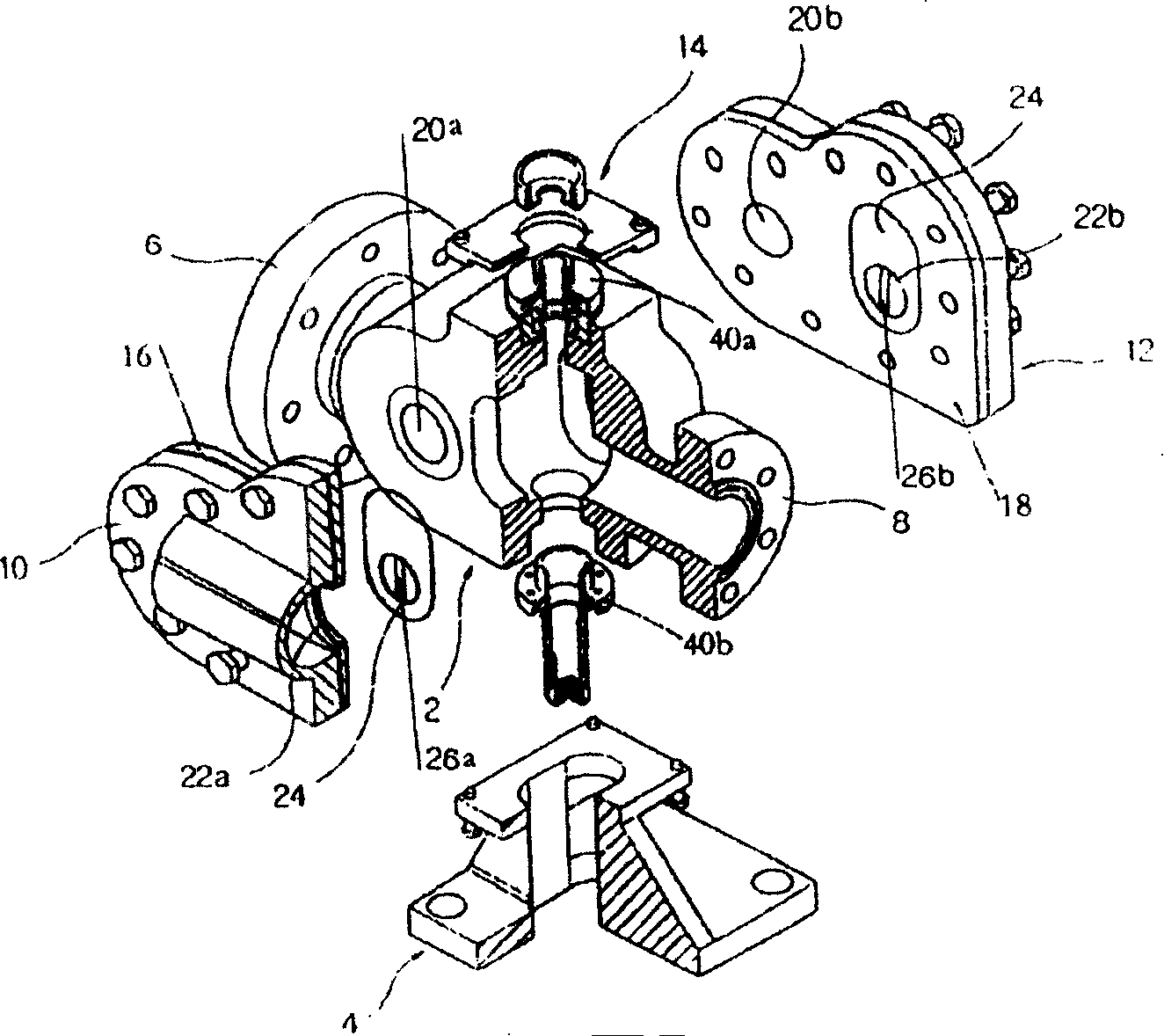

[0029] As attached figure 2 , 3 As shown in Figure 4, a high-pressure valve of the present invention mainly includes a valve body 2 connected to a pipeline through which fluid flows in the horizontal direction. The valve body 2 is connected to the side valve covers 10 and 12 equipped with the valve plates 16, 18 An accommodating space is formed in the accommodating space, and the spool sleeve 30 is arranged in the accommodating space. The spools 32 and 34 are arranged in the spool holes at both ends of the spool sleeve 30. The spools 32 and 34 are pressed into the spool together with the springs S1 and S2 respectively. In the hole, the valve cores 32 and 34 are in contact with the sliding sealing surfaces 24 of the valve plates 16, 18, and the valve core sleeve 30 can be raised and lowered in the containing space. The lower part of the valve stem 36 is connected to the valve core sleeve 30 and the upper part is connected to the driving device 14 to drive The device 14 slides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com