Assembling frame for large scale quick assembling and detecting of fuel battery stack

A technology of fuel cell stacks and assembly racks, which is applied in the direction of fuel cells, circuits, electrical components, etc., and can solve the problems of being unable to achieve rapid assembly and testing and spending a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

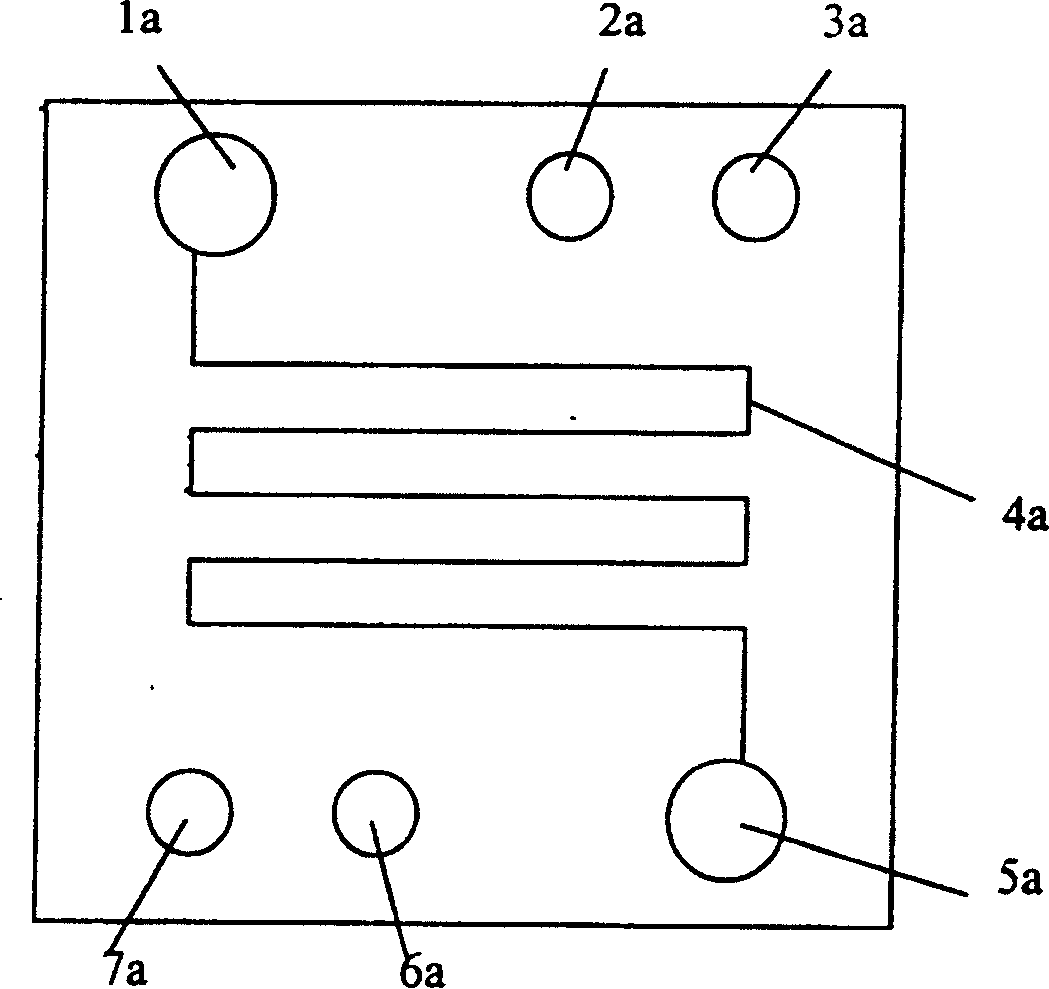

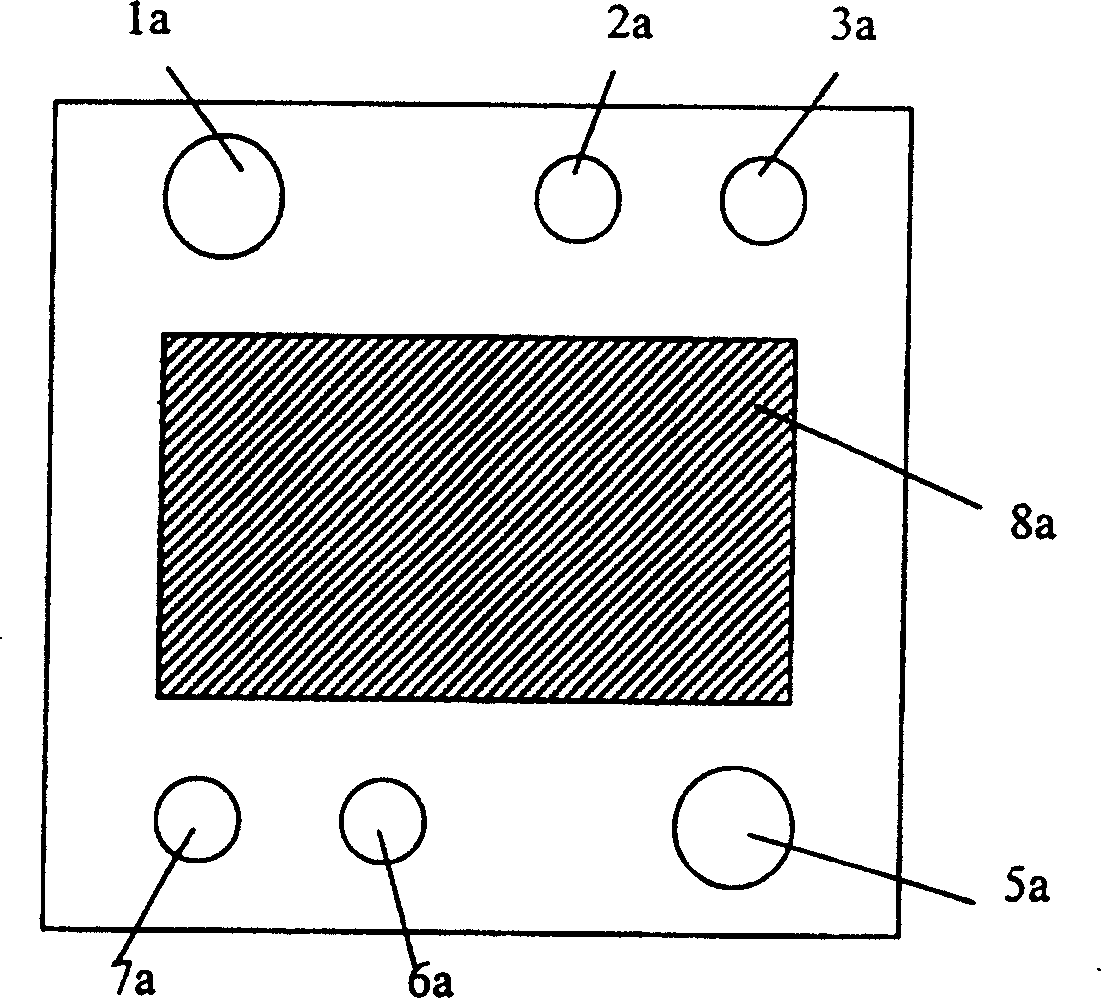

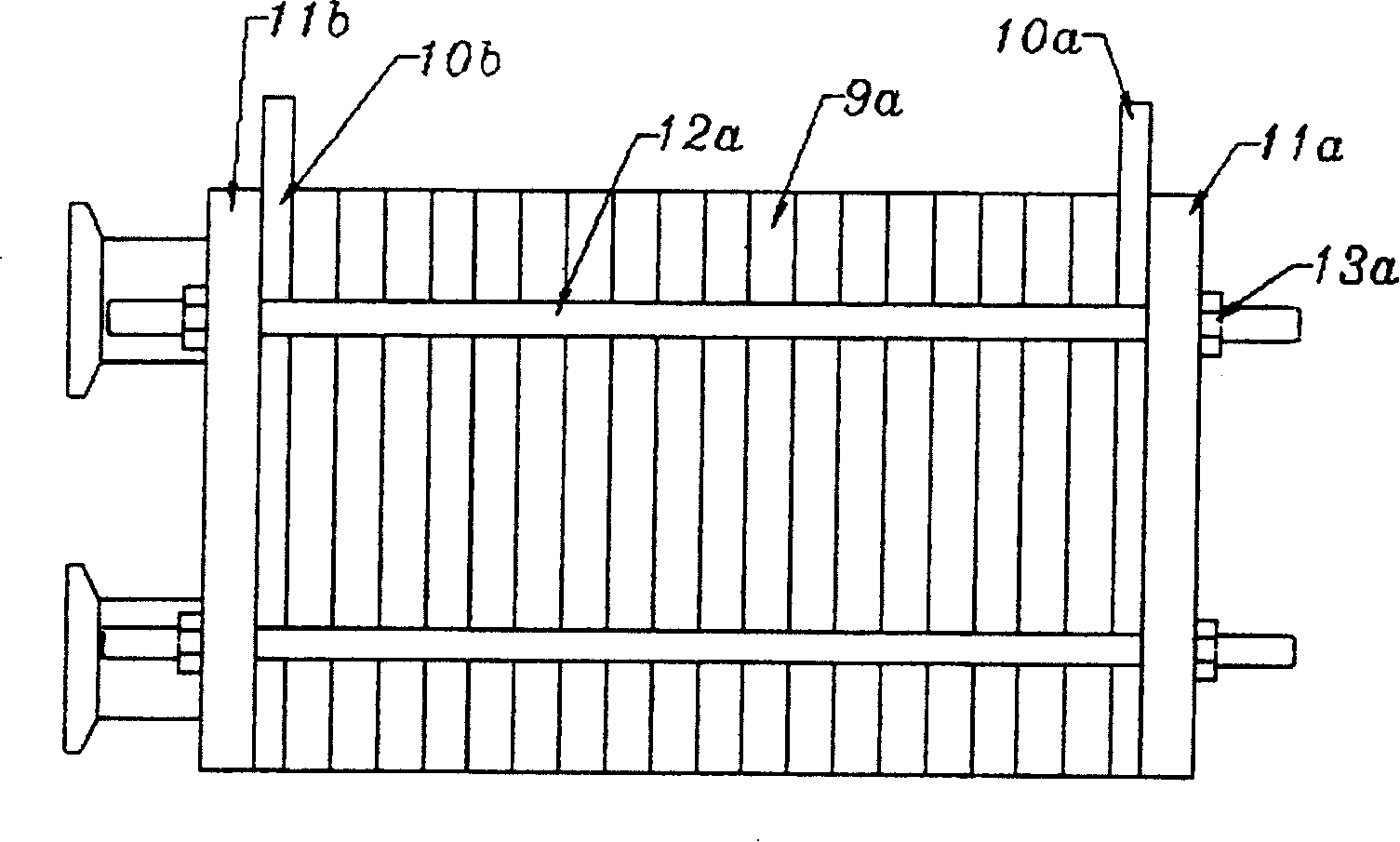

[0039] Such as Figure 4 As shown, an assembly frame suitable for large-scale rapid assembly and testing of fuel cell stacks, the assembly frame includes a workbench 1, a pressure adjustable pressing device 2, and a positioning guide rod 3, and the workbench is provided with a plate-type table 11 , used to support the pressure-adjustable compression device 2 and the fuel cell stack 4 to be assembled and tested, the pressure-adjustable compression device 2 is arranged at one end of the table 11, and the fuel cell stack 4 is arranged on the table 11 The other end of the positioning guide rod 3 is provided with four, and the positioning guide rod 3 is vertically penetrated on the front and rear end plates 41, 42 of the fuel cell stack 4 along the axial direction, wherein the four positioning guide rods 3 are respectively Set on the left, right and bottom of the front and rear end plates 41, 42 of the fuel cell stack 4 to be assembled and tested, the two on the left and right are ...

Embodiment 2

[0045] Please refer to Figure 4 , In this embodiment, the fuel cell stack 4 is composed of a front end plate, a positive electrode conductive current collector plate, 100 single cells, a negative electrode conductive current collector plate and a rear end plate. The single cell is 206mm high and 206mm wide. Four positioning guide rods 3 are arranged on the assembly frame, two at the bottom (not shown), and two at the left and right. The bottom two are used to support the fuel cell stack. The surface is very smooth, which is conducive to sliding when the fuel cell stack is compressed by the pressure of the compression device. The distance between the left and right two is slightly wider than 206mm by 0.05mm-0.20mm , which is conducive to the tidy assembly of each single battery.

[0046] The pressing device 2 adopts a hydraulic jack type jack 21, and when the pressure of the jack is increased to 10 kg / cm2 by the hand-operated hydraulic lever, the jack 21 will press the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com