Surface treatment method and instrument of air bubble utilizing backing

A substrate surface and substrate technology, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of microparticle pollution, restrictions on the shape and size of materials to be treated, and large electric energy. It achieves the effect of no particle pollution, high flexibility in processing size, and no need for high-speed rotating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

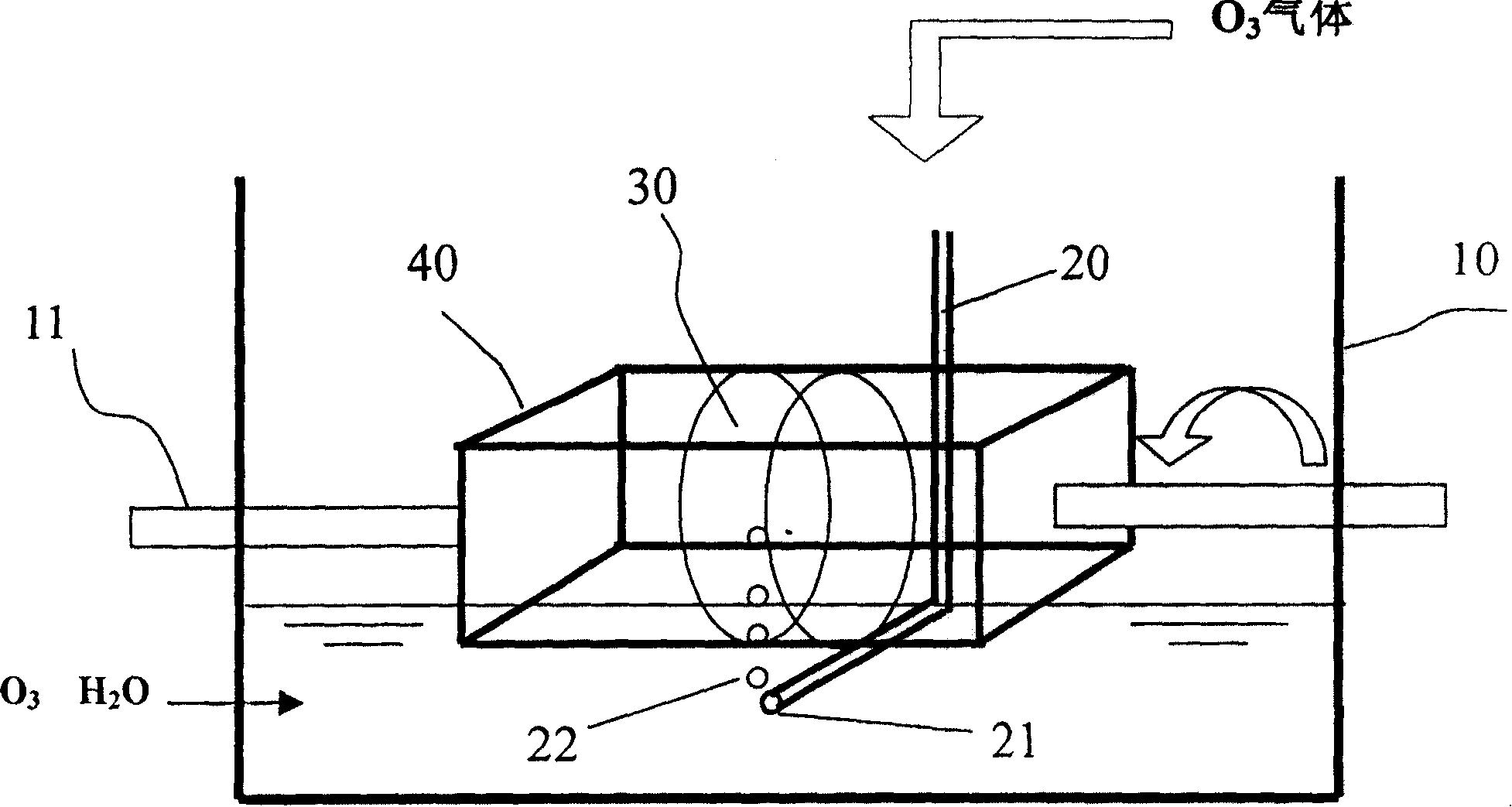

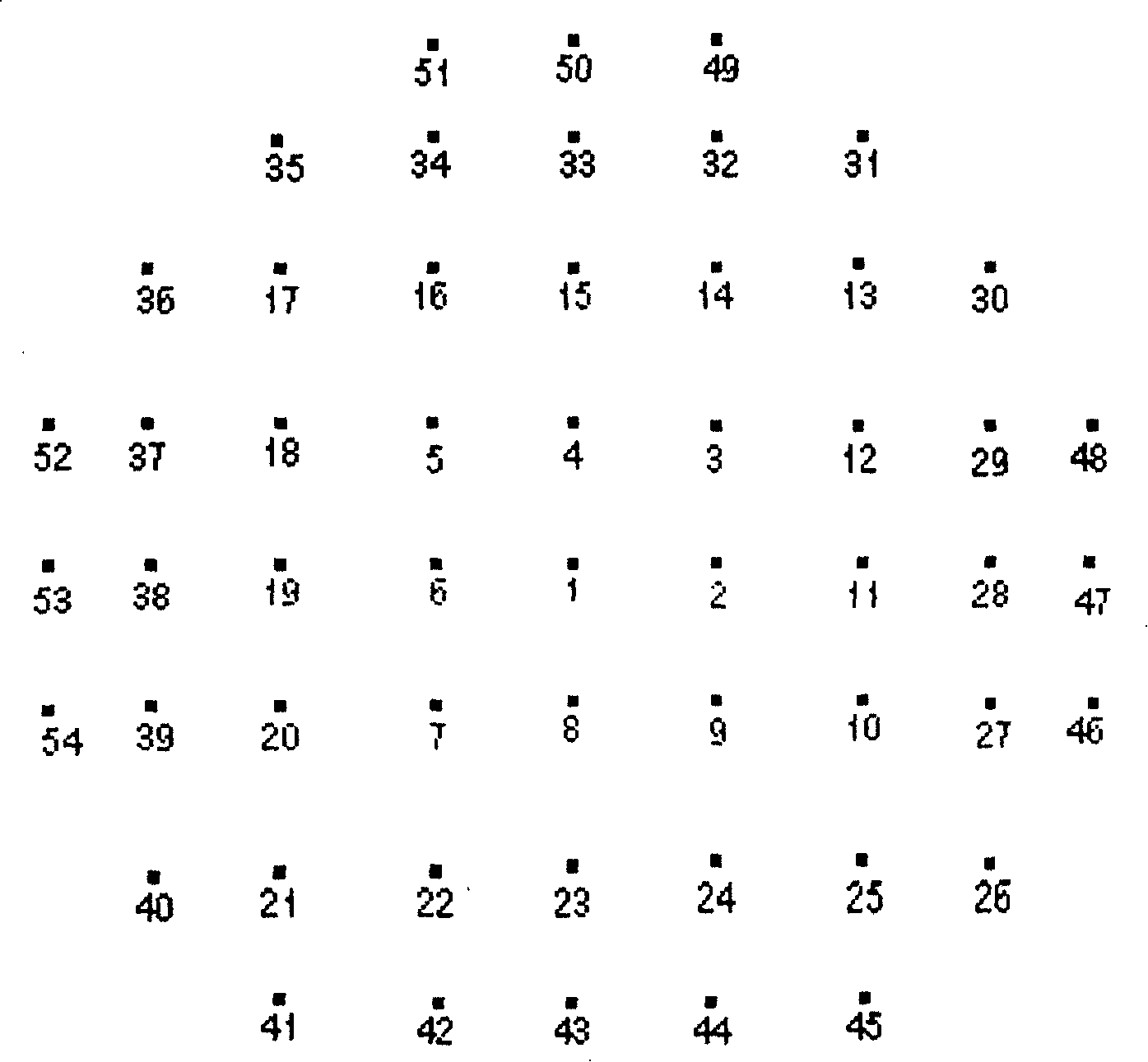

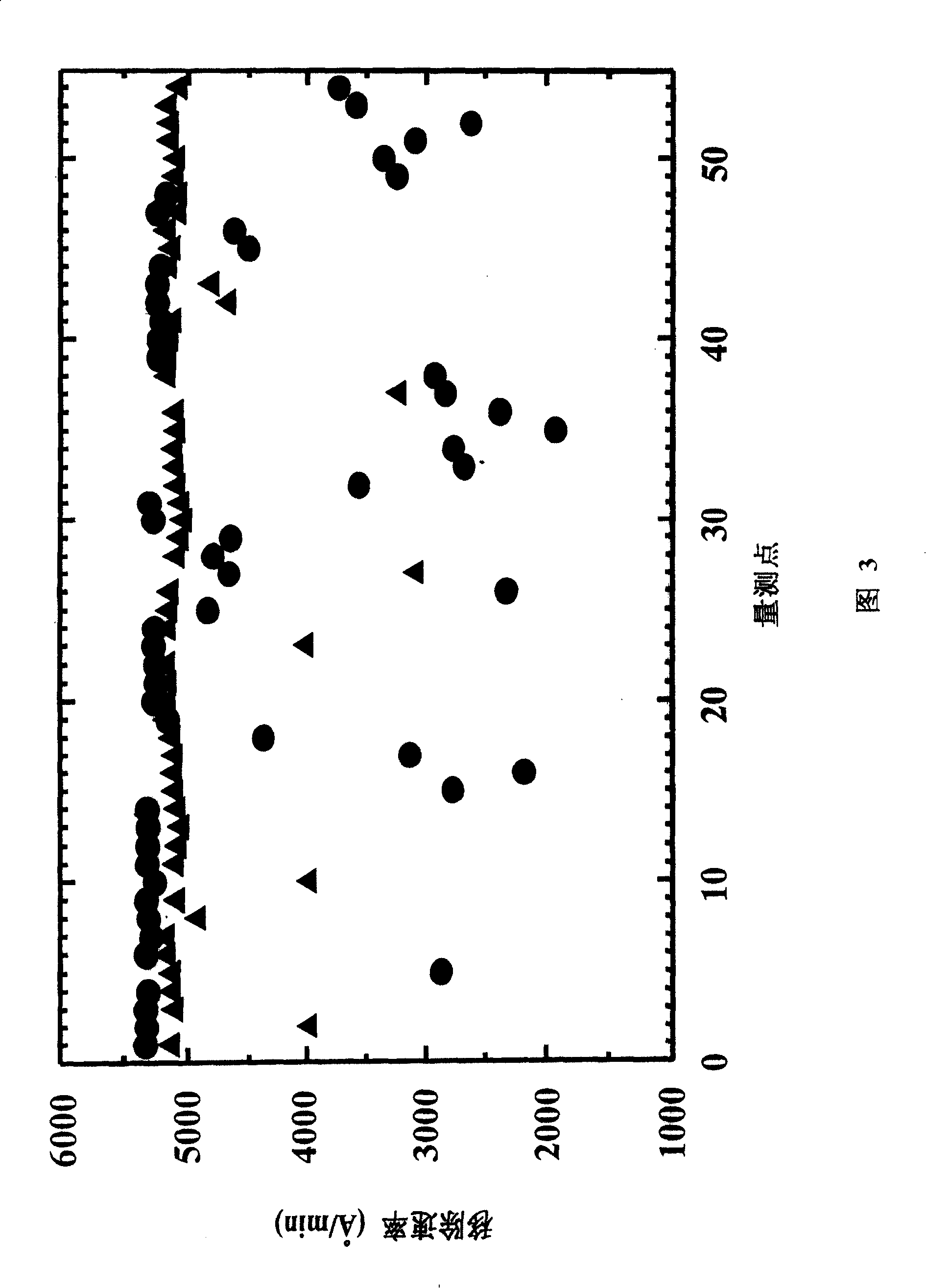

Embodiment 1

[0034] Coat the two sheets with a thickness of about 10000 A wafer of photoresist (Model FH-6400L) was placed as figure 1 The apparatus shown performs photoresist removal on the wafer. Before removing the photoresist, use OLYMPUSnanospec to measure the photoresist thickness at 54 points on the wafer, the positions of the 54 points are as follows figure 2 shown. About 1 / 3 of the wafer near the bottom (about 2.8 cm) is immersed in ultrapure water, and the ultrapure water is maintained at a temperature of 50° C. during cleaning. The air supply pipe 20 is provided with an opening with a diameter of about 0.1 mm, and the air supply pipe 20 is connected with an odor generator (Anseros, Germany). The flow rate of the ozone gas is 90 NL / hr (the ozone concentration of the ozone gas is 17% (w / w)). Activate the rotating shaft 11 to start cleaning, and rotate the support box 40 at 3-4 rpm. Cleaning time is 2 minutes. The cleaned wafer was rinsed with deionized water, and dried wit...

Embodiment 2 and 3

[0039] Except that the temperature of the ultrapure water was changed to room temperature and 80° C., the procedure in Example 1 was repeated for 2 minutes. Table 1 shows the average removal rate of Examples 1-3.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com