Movable welding rod constant temperature material supply box

A feeding box and mobile technology, which is applied in the field of mobile electrode constant temperature feeding box, can solve the problems of unpractical secondary waste, easy moisture regain, large electric power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

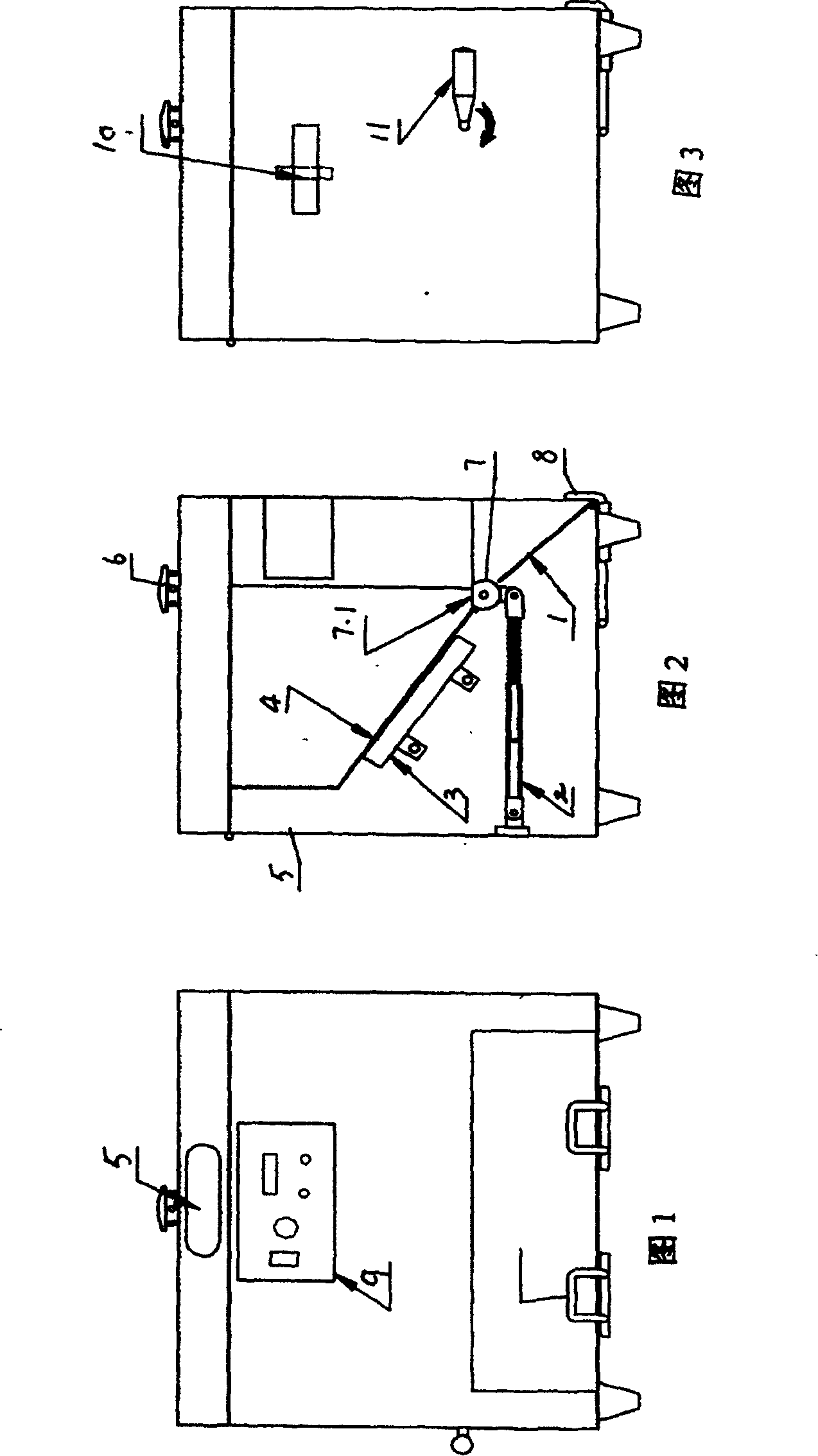

[0012] Referring to Figures 1, 2, and 3, the mobile electrode constant temperature feeding box of the present invention is mainly composed of a feeding box 5, a heat dissipation punching inclined plate 4, an electric heater 3, a feeding shaft 7, a feeding handle 11, and a guiding inclined plate 1 , electrode bracket 8, reactor 2 and control panel 9. The heat dissipation punching slant plate 4 is arranged obliquely forward in the material box 5, the electric heater 3 is arranged on the back side of the heat dissipation punching slant plate 4, and the unloading shaft 7 is connected between the left and right side walls of the material box 5. The shaft 7 is placed on the front side of the lower edge of the heat-dissipating punching slant plate 4, and the connection between the unloading shaft 7 and the lower edge of the heat-dissipating punching slant plate 4 forms a plane 7.1, and the guide slant plate 1 is arranged obliquely forward in front of the unloading shaft 7 side, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com