Double-helix drying equipment and drying method

A drying equipment and double-screw technology, which is applied in the double-screw drying equipment and drying field, can solve the problems of small drying capacity and large occupied volume, and achieve the effects of cost saving, low power consumption and stable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

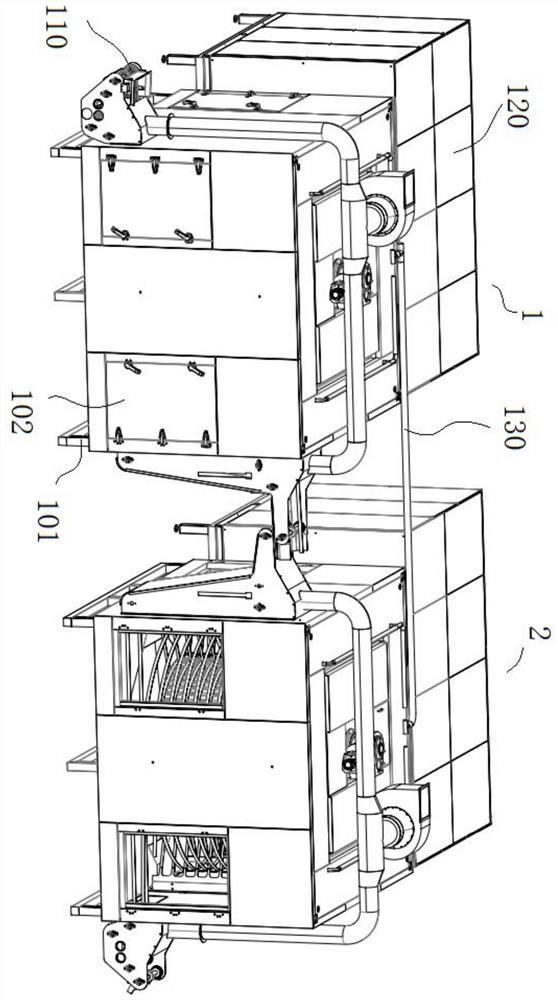

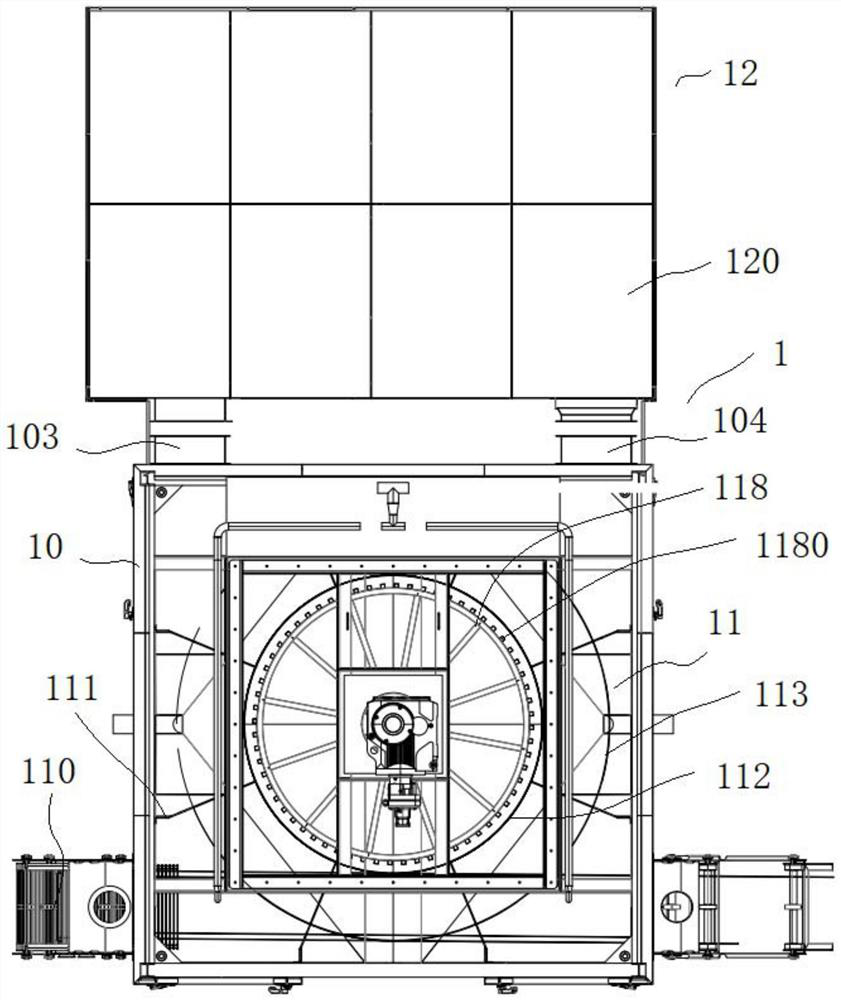

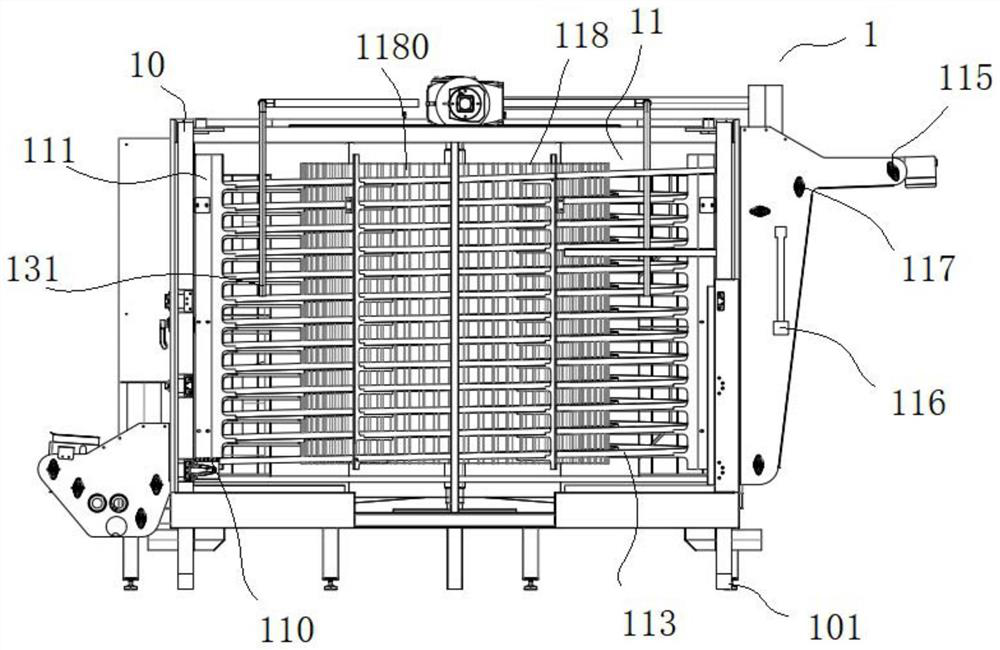

[0041] Figure 1-Figure 6 As shown, the double spiral drying equipment includes a first spiral drying equipment 1 and a second spiral drying equipment 2, the first spiral drying equipment 1 and the second spiral drying equipment 2 are arranged on the left and right, and the first spiral drying equipment The drying raw material outlet of 1 corresponds to the drying raw material inlet of the second spiral drying equipment 2, forming a double-screw drying system.

[0042] The first screw drying device 1 includes an insulated box body 10, a screw conveying mechanism 11, a drying mechanism 12, and a cleaning mechanism.

[0043] like figure 1 As shown, the lower end of the heat preservation box 10 is provided with a bracket 101, the heat preservation box 10 is arranged above the support 101, the screw conveying mechanism 11 is arranged in the heat preservation box 10, the heat preservation box 10 is a double-layer structure, and an insulation layer is arranged in the middle. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com