Method for treating seepage in tiled roof lap seam by profiled steel sheet

A technology for profiled steel plate and tile roofs, applied to roofs, roofs using flat/curved panels, and roof cladding, to improve corrosion resistance, reduce use and maintenance costs, and avoid cut leakage and premature corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

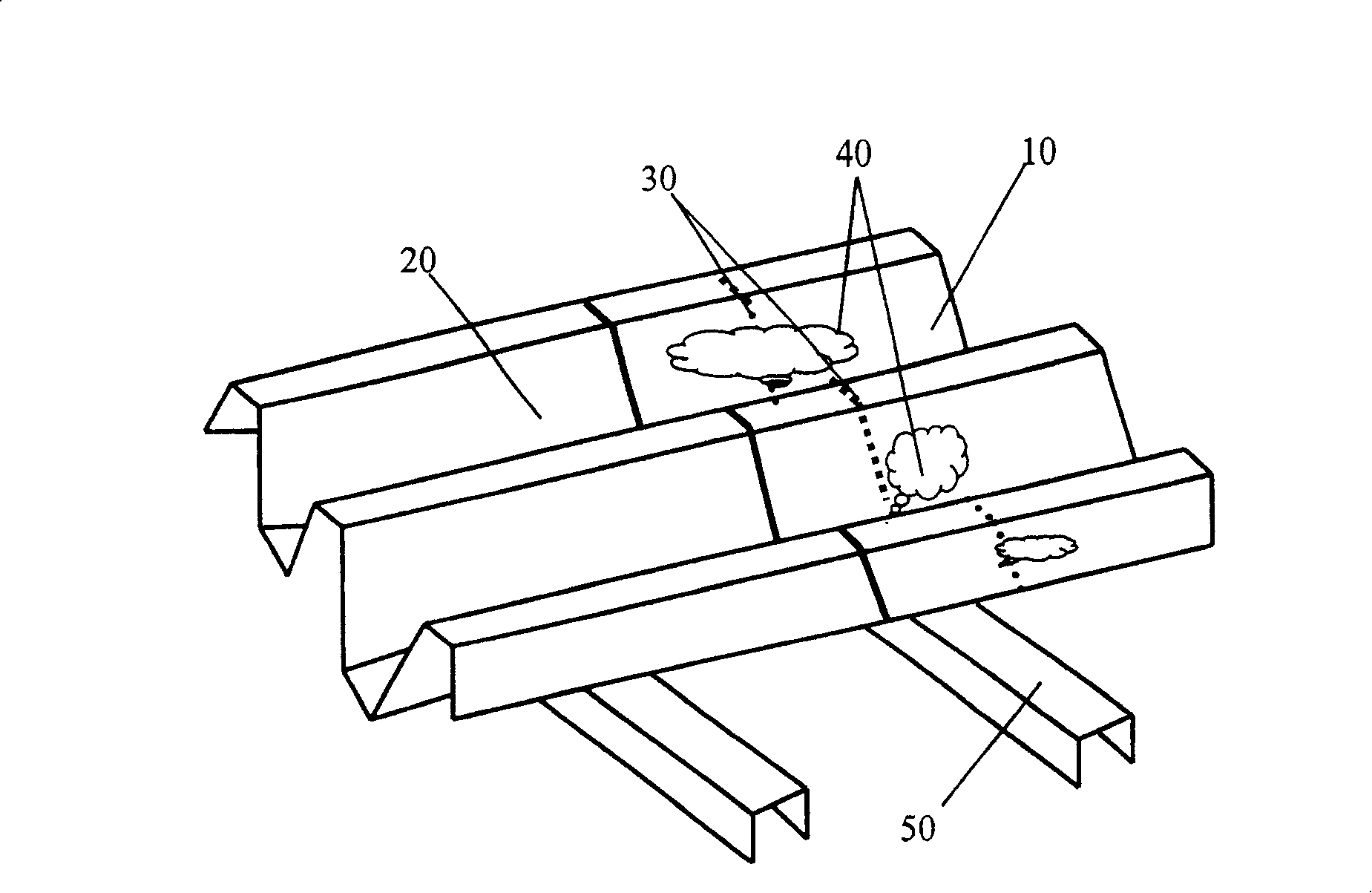

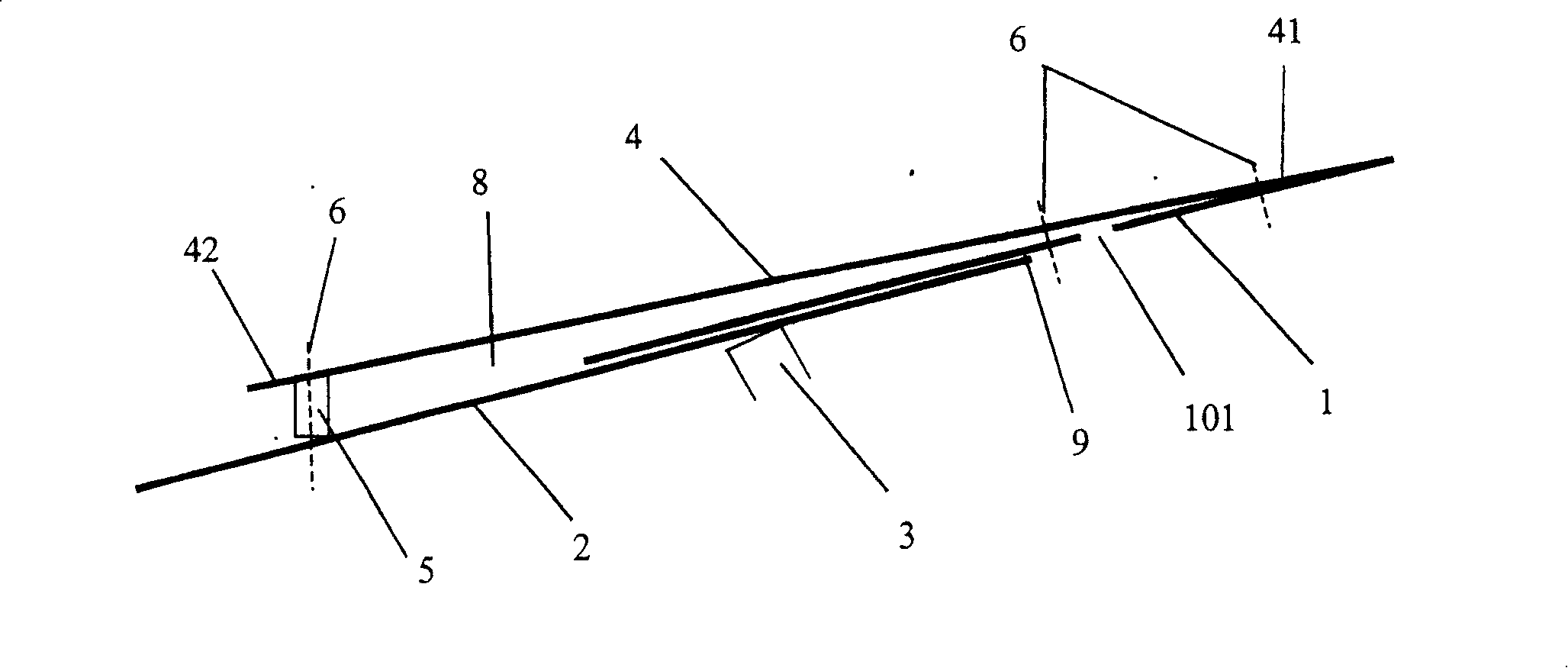

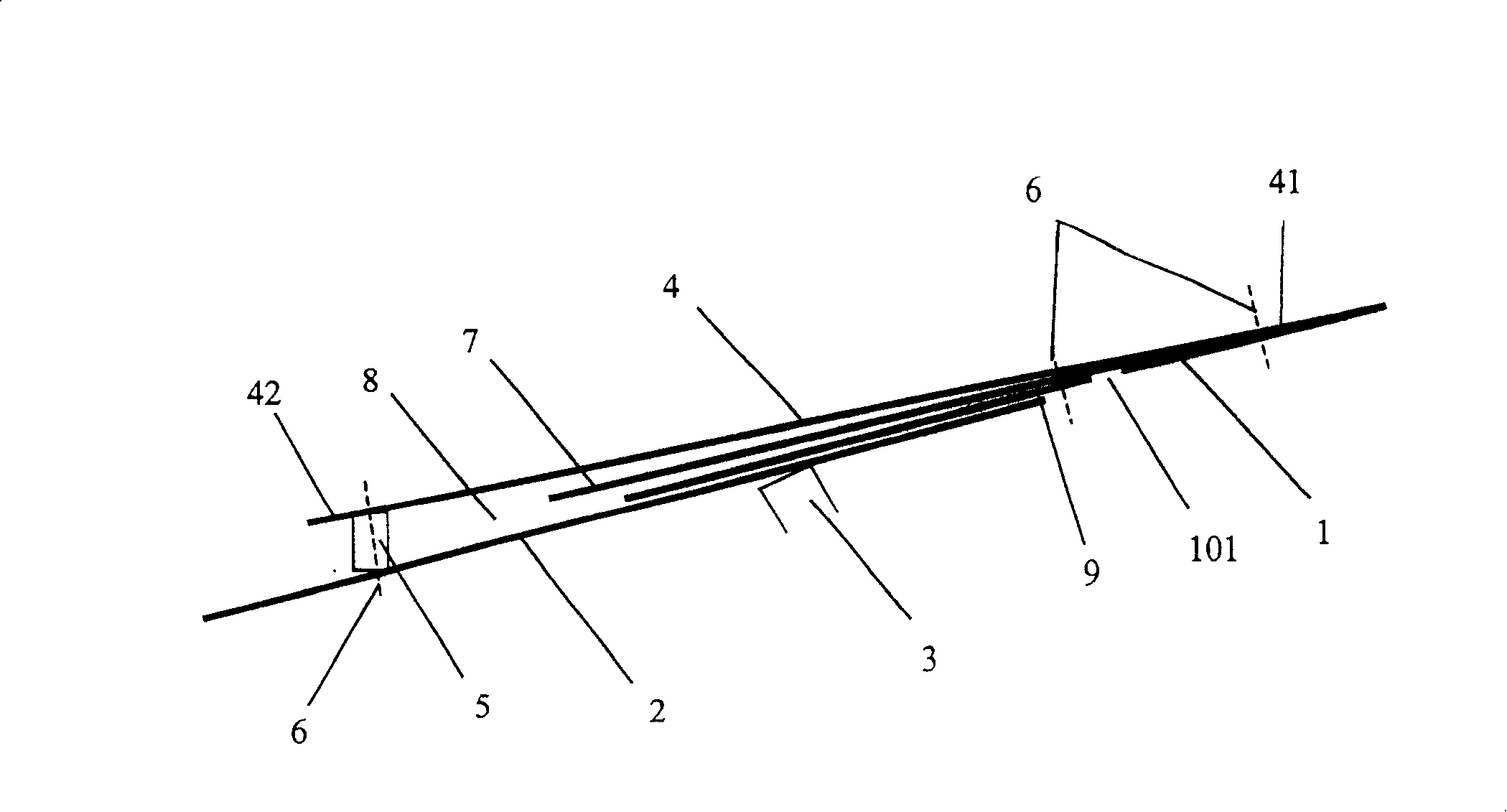

[0019] see figure 2 , a schematic diagram of an embodiment of the present invention to control leakage, on the steel roof truss 3, near the lap joints 9 of the upper tile 1 and the lower tile 2 constituting the profiled steel tile roof, the upper tile 1 is corroded, and the perforation 101 is formed by pressing The steel plate tile is used as the equal pressure plate 4, covering the rusted and perforated part 101 of the upper tile 1, one end of the equal pressure plate 4 - the backwater end 41 is connected and fixed to the perforated upper tile 1, and the other end - the water facing end 42 is connected and fixed to the lower tile 2. Use pads 5 to make the equal pressure plate 4 and the lower tile 2 form an angle, and form an equal pressure space 8 at the overlapping parts of the lower part of the isobaric plate 4 and the original roof tile 1 and lower tile 2, so as to form an internal and external static pressure difference , so as to block rainwater and the like from enteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com