Piston for an internal combustion engine

一种内燃机、活塞的技术,应用在内燃机活塞领域,能够解决耗费等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

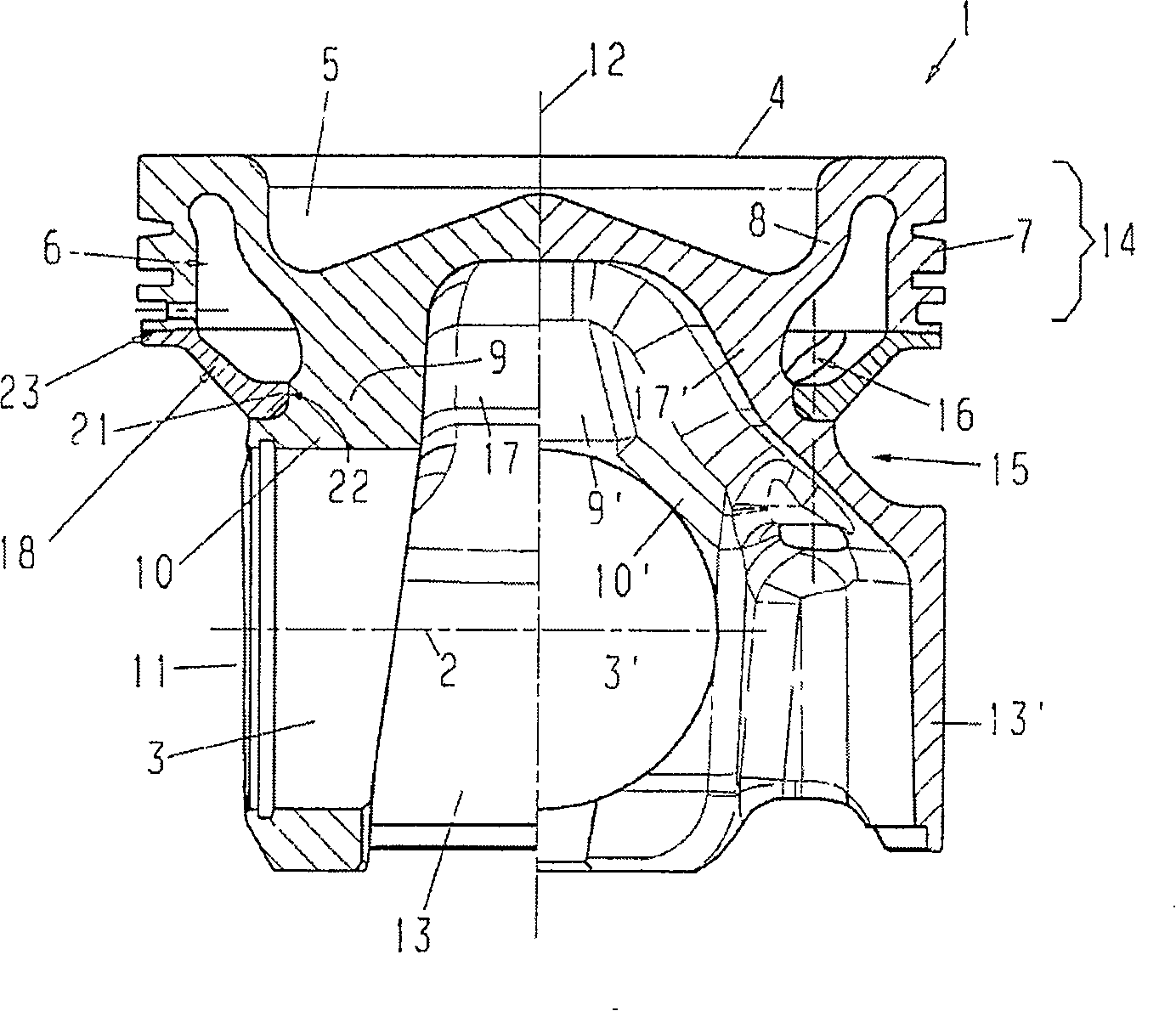

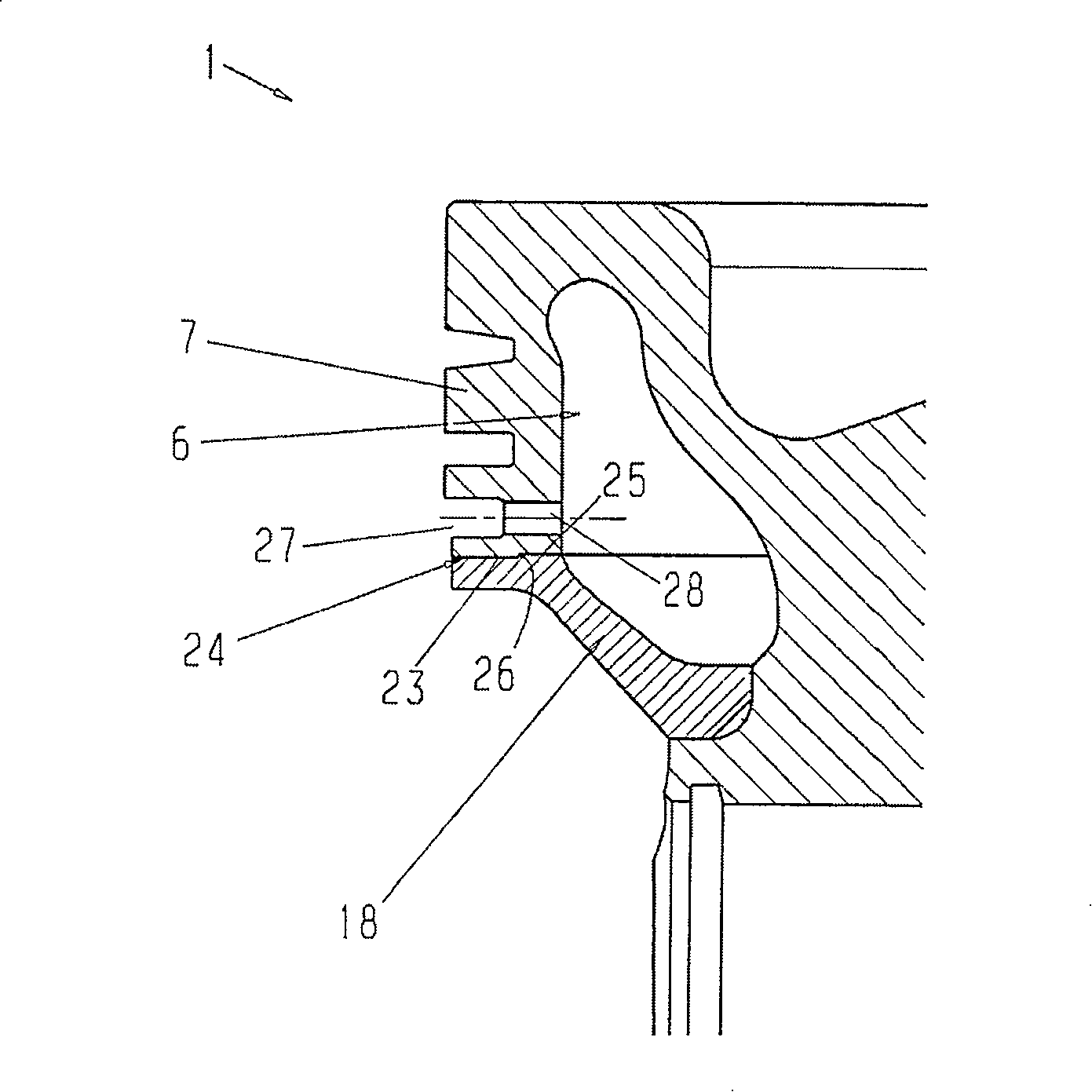

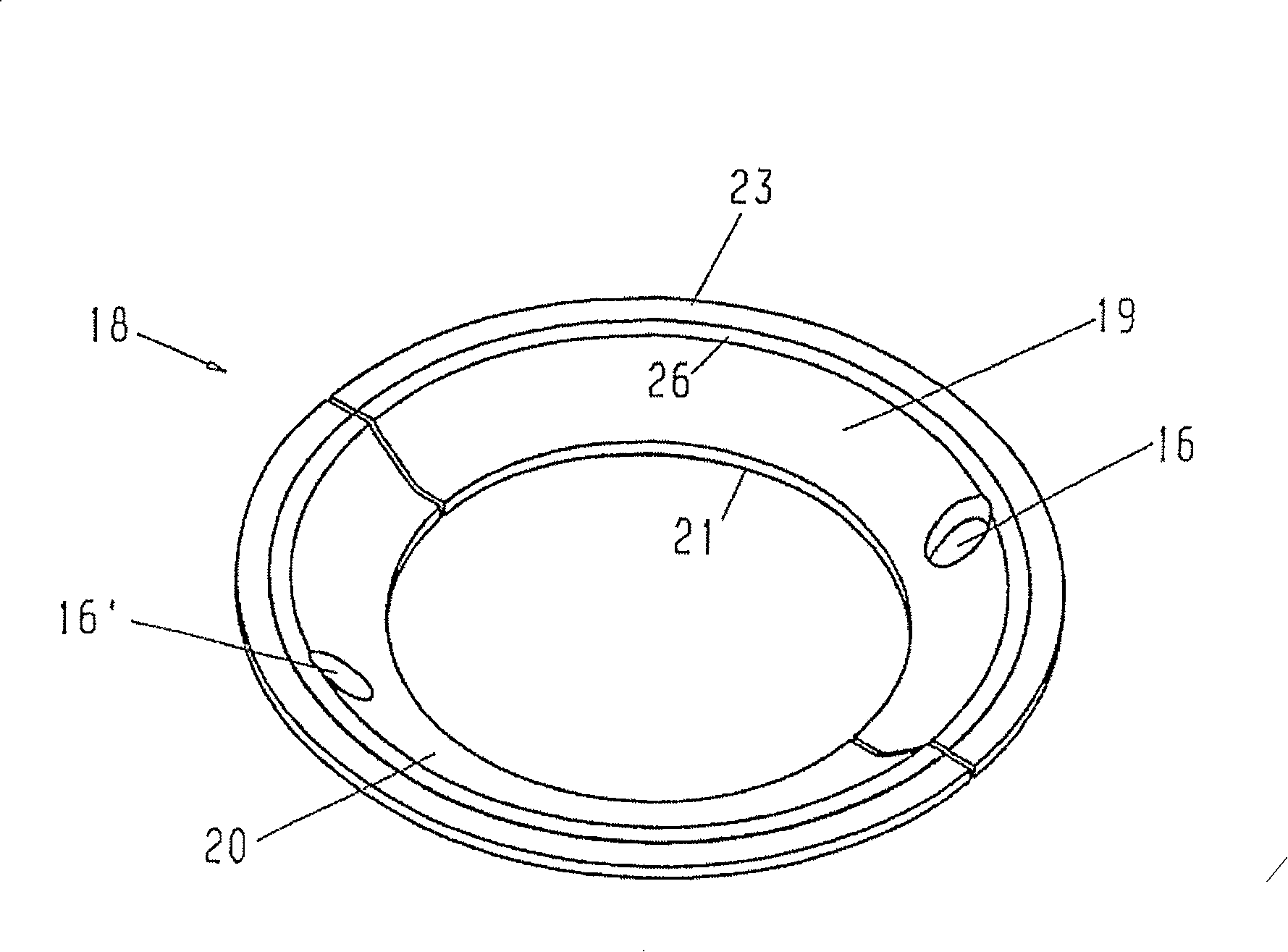

[0041] figure 1 is a one-piece piston 1 of an internal combustion engine shown in a cross-sectional view consisting of two halves, wherein the left half represents a cross-section of the piston 1 along a longitudinal axis 2 of the piston pin hole 3, the right half Shows a longitudinal section of the piston 1 staggered by 90°. The piston 1 is made of steel and has a combustion chamber 5 in the region of the piston crown 4 . An annular cooling channel 6 is arranged in the radially outer region of the piston crown 4, the radially outer boundary of said cooling channel is bounded by a ring wall 7 which conforms to the shape of the piston crown 4, the cooling channel's The radial inner boundary is bounded partly by a ring rib 8, partly by a piston pin support 9, 9' and partly by a piston skirt connection 17, 17'. The ring wall 7 serves here as a piston ring carrier.

[0042] Each piston pin seat 10 , 10 ′ with a piston pin hole 3 , 3 ′ conforms to the outer shape of the piston c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com