Automatic pressure reducing flow stable valve

An automatic decompression and steady flow valve technology, which is applied in fluid pressure control without auxiliary power, safety valve, balance valve, etc., can solve the problem of unstable water pressure, affecting the normal use of water heaters, hot water temperature fluctuating high and low, etc. problem, to achieve the effect of increasing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

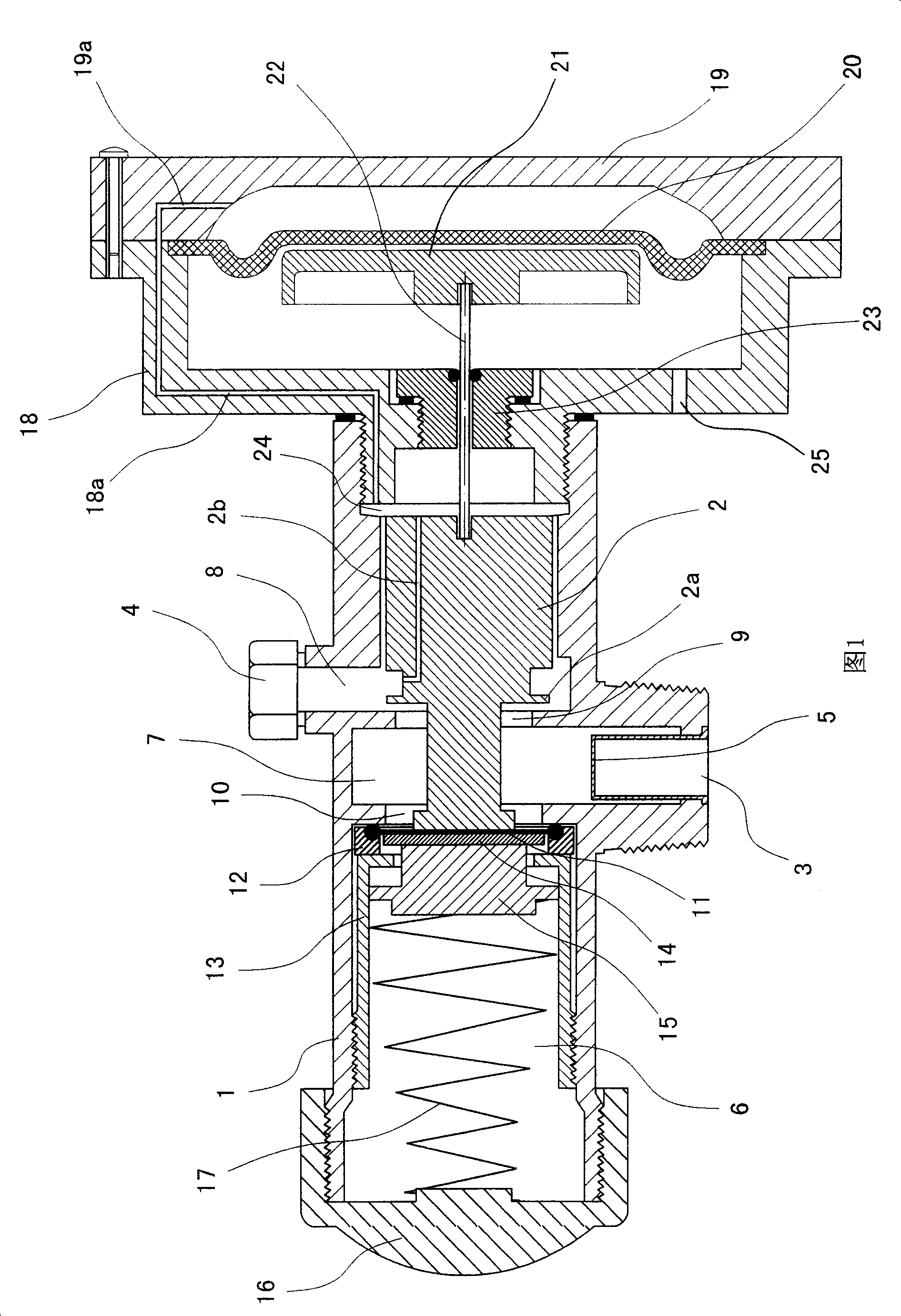

[0020] As shown in Figure 1, it is a preferred embodiment of the present invention. As shown in the figure, the automatic decompression and steady flow valve of this embodiment has a valve body 1 and a valve core 2 , and a fluid inlet 3 and a fluid outlet 4 are provided in the middle of the valve body 1 . A filter screen 5 is provided at the fluid inlet 3 . The inner cavity of the valve body 1 is provided with a spring cavity 6 , a fluid inlet cavity 7 corresponding to the fluid inlet 3 and a fluid outlet cavity 8 corresponding to the fluid outlet 4 from left to right. A flow-restricting hole 9 is provided between the fluid inlet 7 and the fluid outlet 8 , and a through-hole 10 is provided between the spring chamber 6 and the fluid inlet 7 , and the diameter of the through-hole 10 is larger than that of the flow-restricting hole 9 . The valve core 2 extends from the right end of the valve body 1 into the inner cavity of the valve body 1 and is assembled in the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com