Assembly of FPC and PCB

A component and gold finger technology, applied in electrical components, printed circuit components, structural connections of printed circuits, etc., can solve problems such as low welding efficiency, affecting product welding quality, and difficult to effectively bridge FPC and PCB.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

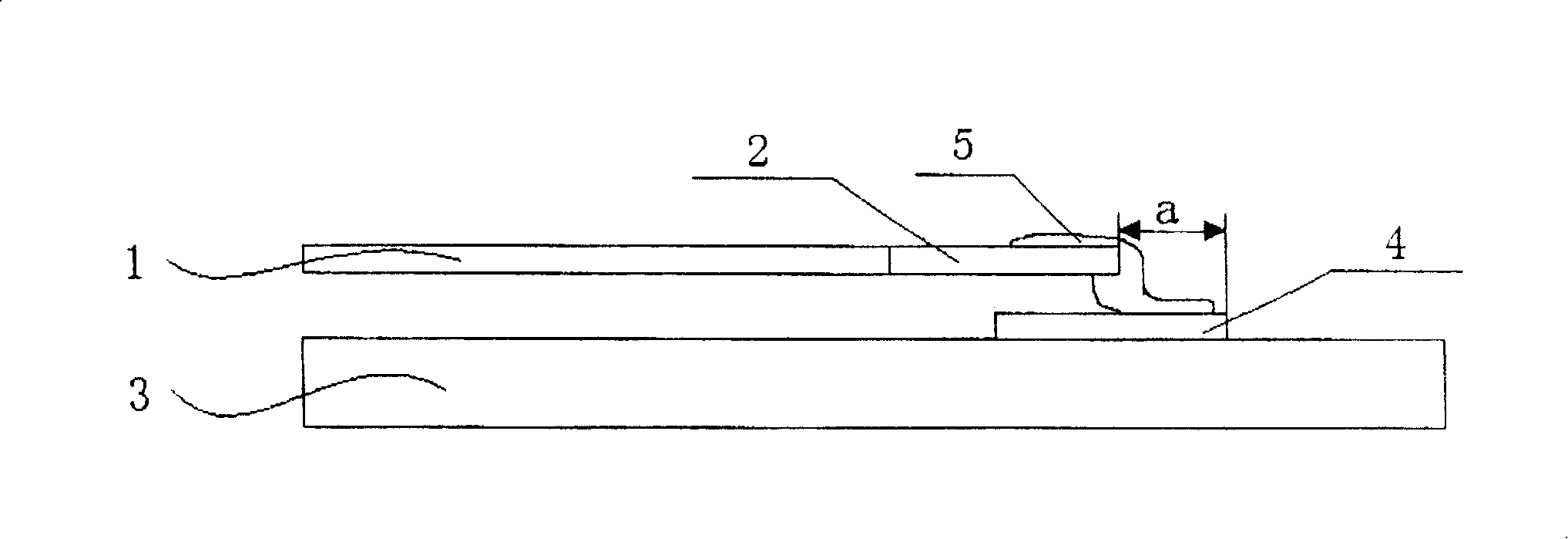

[0009] A FPC and PCB assembly, such as figure 1 As shown, it includes an FPC substrate 1, a gold finger 2 disposed on the end side of the FPC substrate, a PCB 3 and a gold finger 4 located on the end side of the PCB, the gold finger 2 on the FPC substrate extends from the outside to the inside of the FPC substrate 1, and on the FPC substrate The front end of gold finger 2 is set back relative to the front end of gold finger 4 on the PCB and is connected by soldering.

[0010] The golden fingers on the FPC substrate are formed by scraping off the insulating glue on the end side of the FPC substrate.

[0011] In the existing structure where the front end of the gold finger on the FPC substrate is aligned with the front end of the gold finger on the PCB, excess solder may flow inward along the gold finger on the PCB during soldering. Since the gap between the FPC substrate and the PCB is small, redundant The tin will form tin beads and be flattened. After the flattened tin is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com