A kind of preparation method of black phosphorene modified iron oxide composite photoelectrode

A technology of iron oxide light and black phosphorene, applied in the field of materials, can solve the problems that the hydrogen production performance of iron oxide photoelectrodes cannot meet the needs of practical applications, and achieve the effects of promoting separation and transmission, mild experimental conditions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

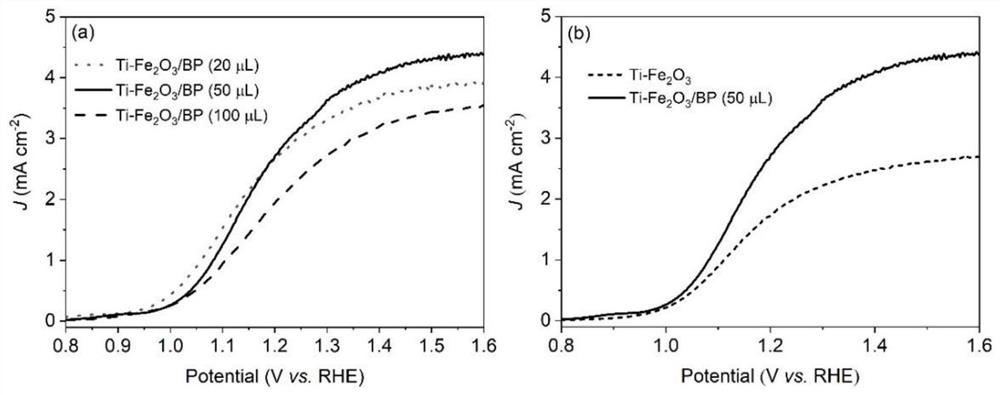

[0031] Example 1: 30 μL of black phosphorene solution was added dropwise on the titanium-treated sample and heated in a vacuum oven at 200° C. for 10 min to obtain a black phosphorene-modified iron oxide composite photoelectrode.

Embodiment 2

[0032] Example 2: 100 μL of black phosphorene solution was added dropwise on the titanium-treated sample and heated in a vacuum oven at 100° C. for 30 minutes to obtain a black phosphorene-modified iron oxide composite photoelectrode.

Embodiment 3

[0033] Example 3: 50 μL of black phosphorene solution was added dropwise on the titanium-treated sample and heated in a vacuum oven at 150° C. for 20 minutes to obtain a black phosphorene-modified iron oxide-iron composite photoelectrode.

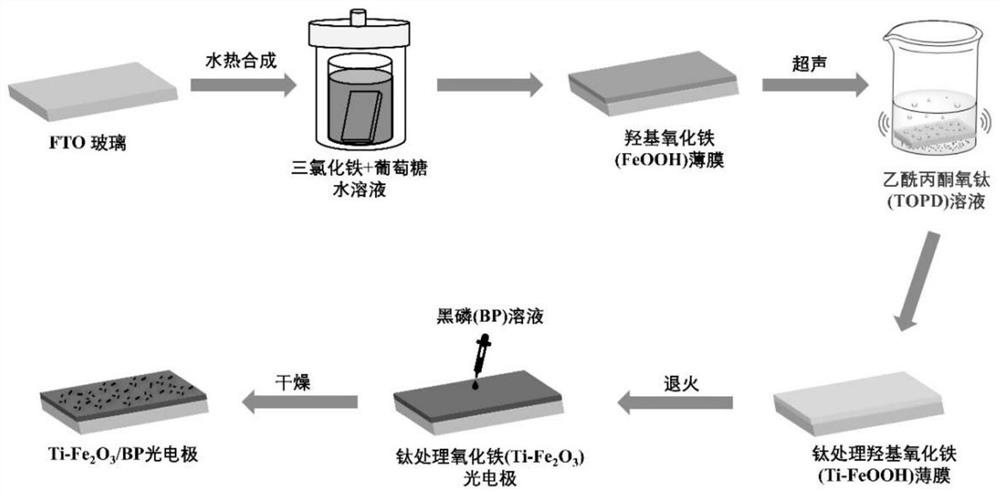

[0034] figure 1Flowchart for the fabrication of black phosphorene-supported iron oxide composite photoelectrodes. First, the FTO conductive glass with FeOOH film was put into TOPD solution for ultrasonication, and then it was transformed into titanium-treated iron oxide photoelectrode by high-temperature annealing. Finally, a black phosphorene-modified iron oxide composite photoelectrode (Ti-Fe 2 o 3 / BP).

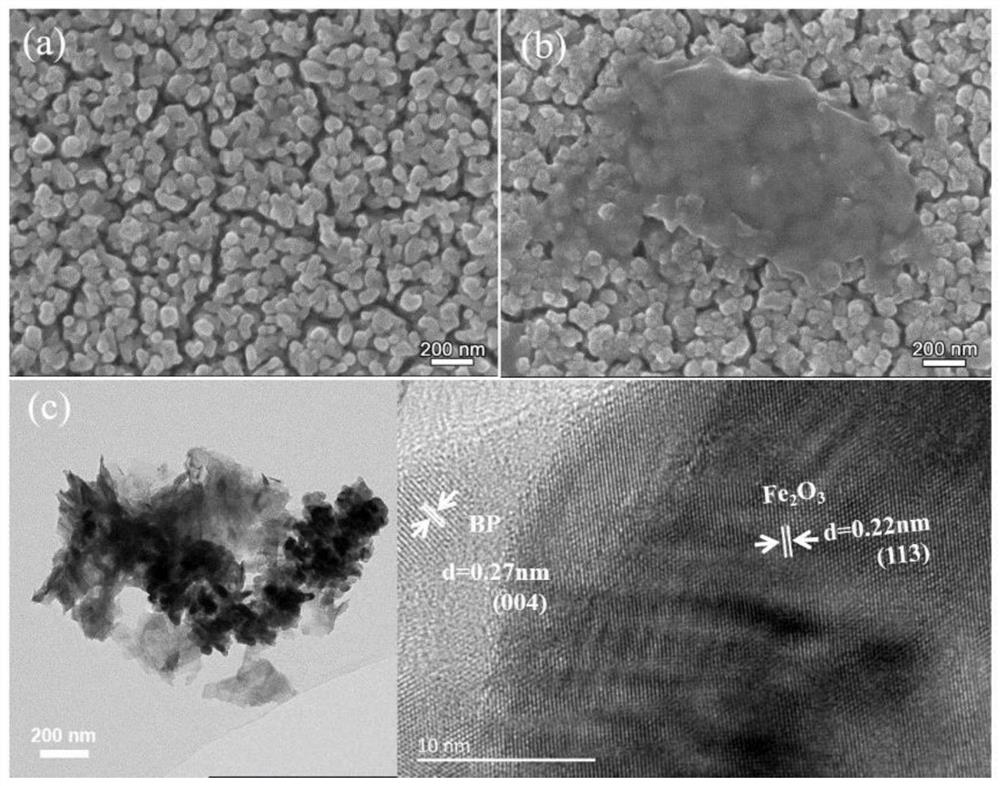

[0035] figure 2 It is the SEM topography contrast figure and HRTEM figure among the embodiment 3. in figure 2 a, 2b Scanning electron microscopy (SEM) was used to study titanium-treated iron oxide (Ti-Fe 2 o 3 ) photoelectrode and titanium-treated iron oxide photoelectrode loaded with black phosphorene (Ti-Fe 2 o 3 / BP) morp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com