Glass fiber yarn impregnating compound as well as preparation method and application thereof

A technology for glass fiber yarn and sizing agent, applied in the field of glass fiber yarn sizing agent and its preparation, can solve problems such as pollution, achieve the effects of reducing exhaust gas/smoke, improving mechanical properties, and avoiding cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

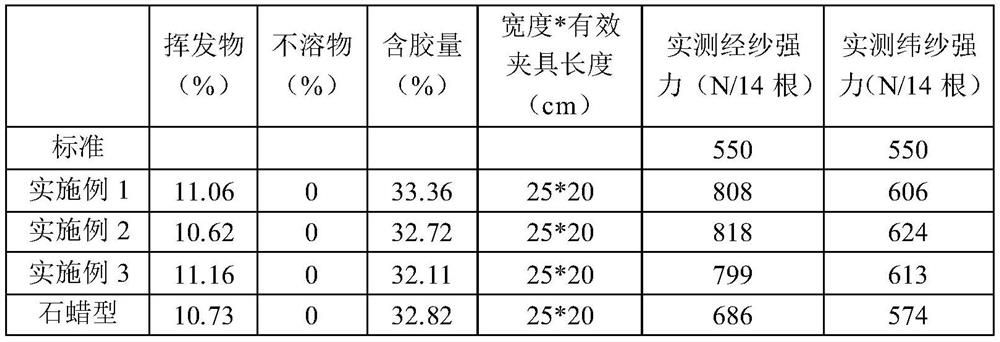

Examples

Embodiment 1

[0035] A glass fiber yarn sizing agent, comprising the following materials by weight: 0.03% of glacial acetic acid, 0.35% of silane coupling agent KH560, 3.5% of modified water-based epoxy resin, 0.82% of epoxy-modified polyester, and 0.82% of modified water-based polyurethane 6.55%, the balance is water.

[0036] Wherein, the preparation method of the modified water-based epoxy resin includes the following steps: dissolving 40 parts by weight of diethanolamine in 30 parts by weight of ethanol to obtain a mixed solution; putting 90 parts by weight of epoxy resin E51 into a reaction kettle, and heating up to 80° C. , pass the cooling water, drop the mixed solution in 60min, pay attention to control the speed and reaction temperature of the mixed solution during the dropwise addition to prevent the material from being flushed, after the end of the dropwise addition, the temperature is kept at 80 °C for 120min and the reaction is continued for 120min. Cooling to 60°C, adding 50 p...

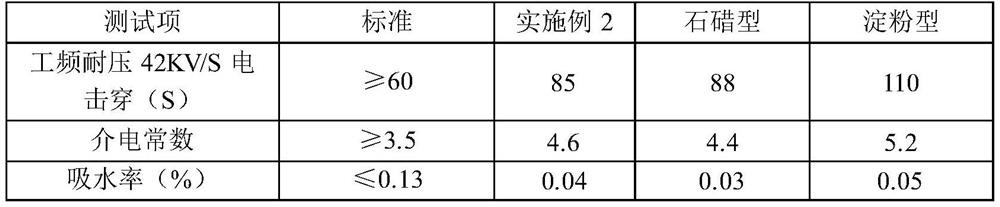

Embodiment 2

[0045] A glass fiber yarn sizing agent, comprising the following materials by weight: 0.065% of glacial acetic acid, 0.55% of silane coupling agent KH560, 4.3% of modified water-based epoxy resin, 0.88% of epoxy-modified polyester, and modified water-based polyurethane 7.2%, the balance is water.

[0046] Wherein, the preparation method of modified water-based epoxy resin includes the following steps: dissolving 35 parts by weight of diethanolamine in 35 parts by weight of ethanol to obtain a mixed solution; putting 100 parts by weight of epoxy resin E51 into a reaction kettle, and heating to 75° C. , pass the cooling water, drop the mixed solution in 80min, pay attention to control the speed and reaction temperature of the dropwise addition of the mixed solution in the process of dropping to prevent the material from being flushed, after the end of the dropwise addition, 75 ℃ of insulation continues to react for 180min, after the end of the reaction Cooling to 50°C, adding 60...

Embodiment 3

[0052] A glass fiber yarn sizing agent, comprising the following materials by weight: 0.1% of glacial acetic acid, 0.7% of silane coupling agent KH560, 4.8% of modified water-based epoxy resin, 0.96% of epoxy-modified polyester, and 0.96% of modified water-based polyurethane 7.65%, the balance is water.

[0053] Wherein, the preparation method of modified water-based epoxy resin includes the following steps: dissolving 30 parts by weight of diethanolamine in 40 parts by weight of ethanol to obtain a mixed solution; putting 120 parts by weight of epoxy resin E51 into a reaction kettle, and heating up to 75° C. , pass the cooling water, drop the mixed solution in 100min, pay attention to control the speed and reaction temperature of the mixed solution during the dropwise addition to prevent the material from being washed, after the dropwise addition is completed, the temperature is kept at 75°C for 120min and the reaction is completed. Cooling to 50°C, adding 65 parts by weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com