Spiral basalt micro-rib and preparation method thereof

A basalt and spiral technology, which is applied in the field of new composite materials, can solve the problems of complex manufacturing process of ribbed micro-reinforcement, weak sliding energy dissipation capacity of micro-reinforcement, and decreased toughening effect of concrete, so as to avoid agglomeration and brittle fracture Phenomenon, superior slip energy dissipation capacity, full effect of bond-slip curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

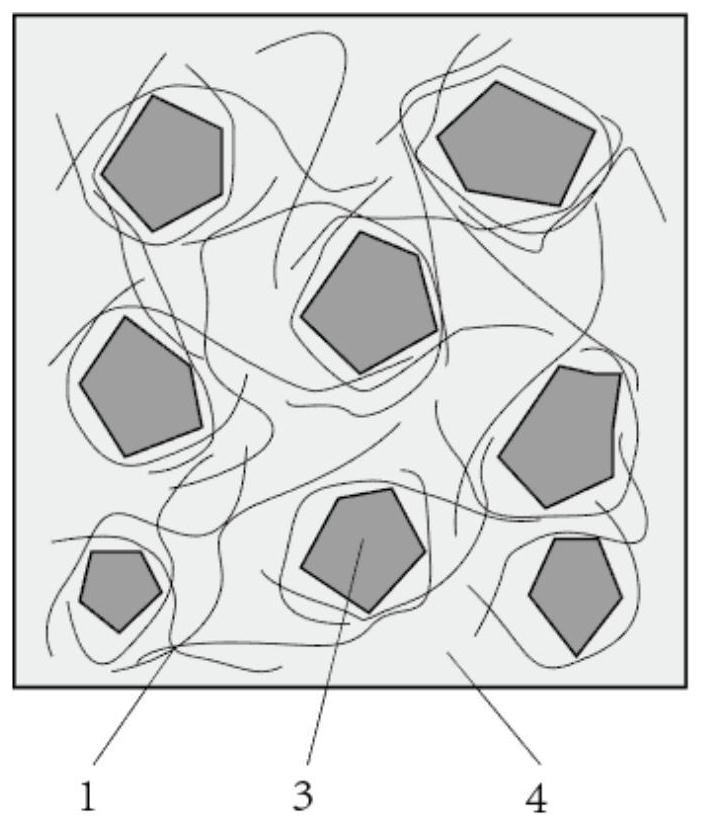

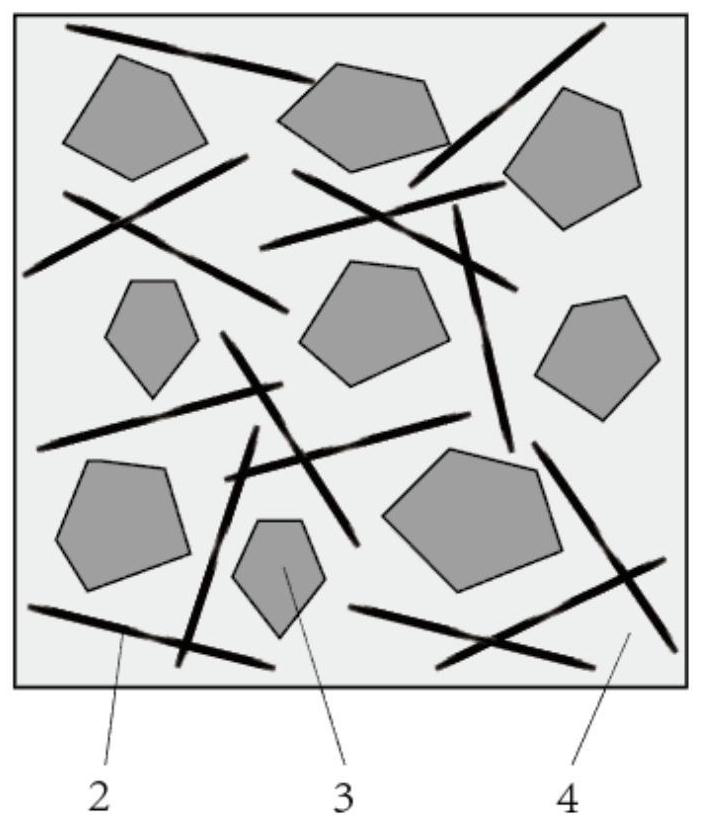

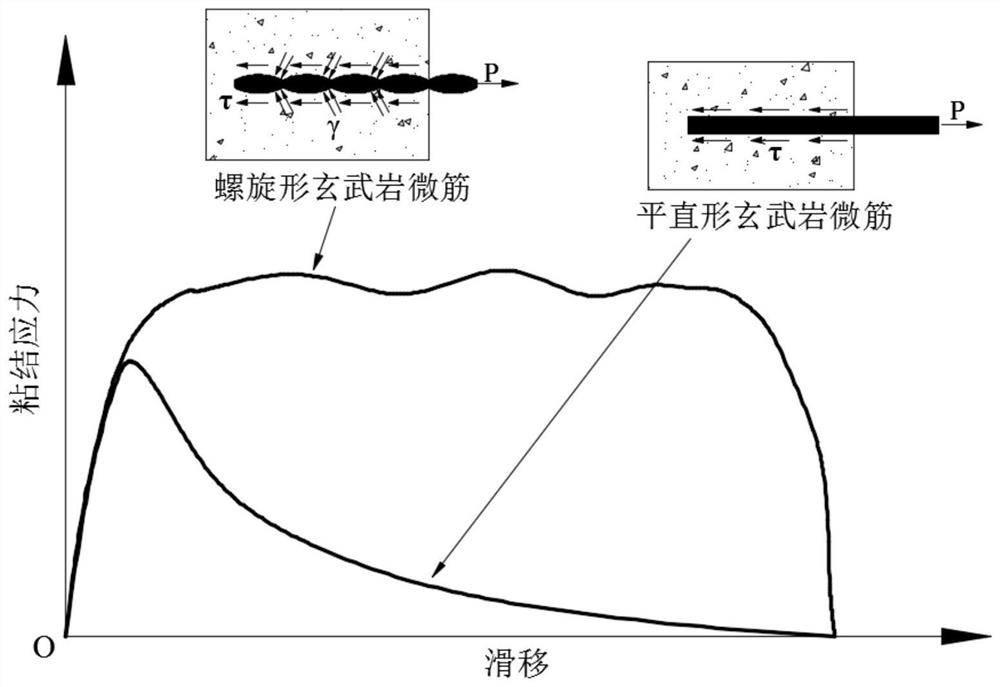

[0028] A spiral basalt micro-reinforcement, the cross section of which is as follows image 3 As shown, it includes monofilament fiber 1 and alkali-resistant sizing agent 5 . The monofilament fiber 1 is a basalt monofilament fiber; the alkali-resistant sizing agent 5 is a modified alkali-resistant epoxy resin. 500-1500 parallel monofilament fibers 1 are clustered and bonded by alkali-resistant sizing agent 5, extruded, spirally twisted, dried and hardened, and cut to obtain spiral basalt micro-reinforcements with a rectangular cross-section (aspect ratio of 2 , equivalent diameter 0.55mm), the length is 35mm, the pitch is 20mm, the appearance of micro-reinforcement is as follows Figure 4 shown.

[0029] Figure 1 compares the distribution of basalt monofilament fibers and spiral basalt micro-reinforcements in fresh concrete. It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com