Fixture

A technology of fixtures and clamping parts, applied in the direction of manufacturing tools, workpiece clamping devices, cleaning methods and appliances, etc., can solve the problems of small size, high precision requirements, and high difficulty in fixing, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The clamp of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

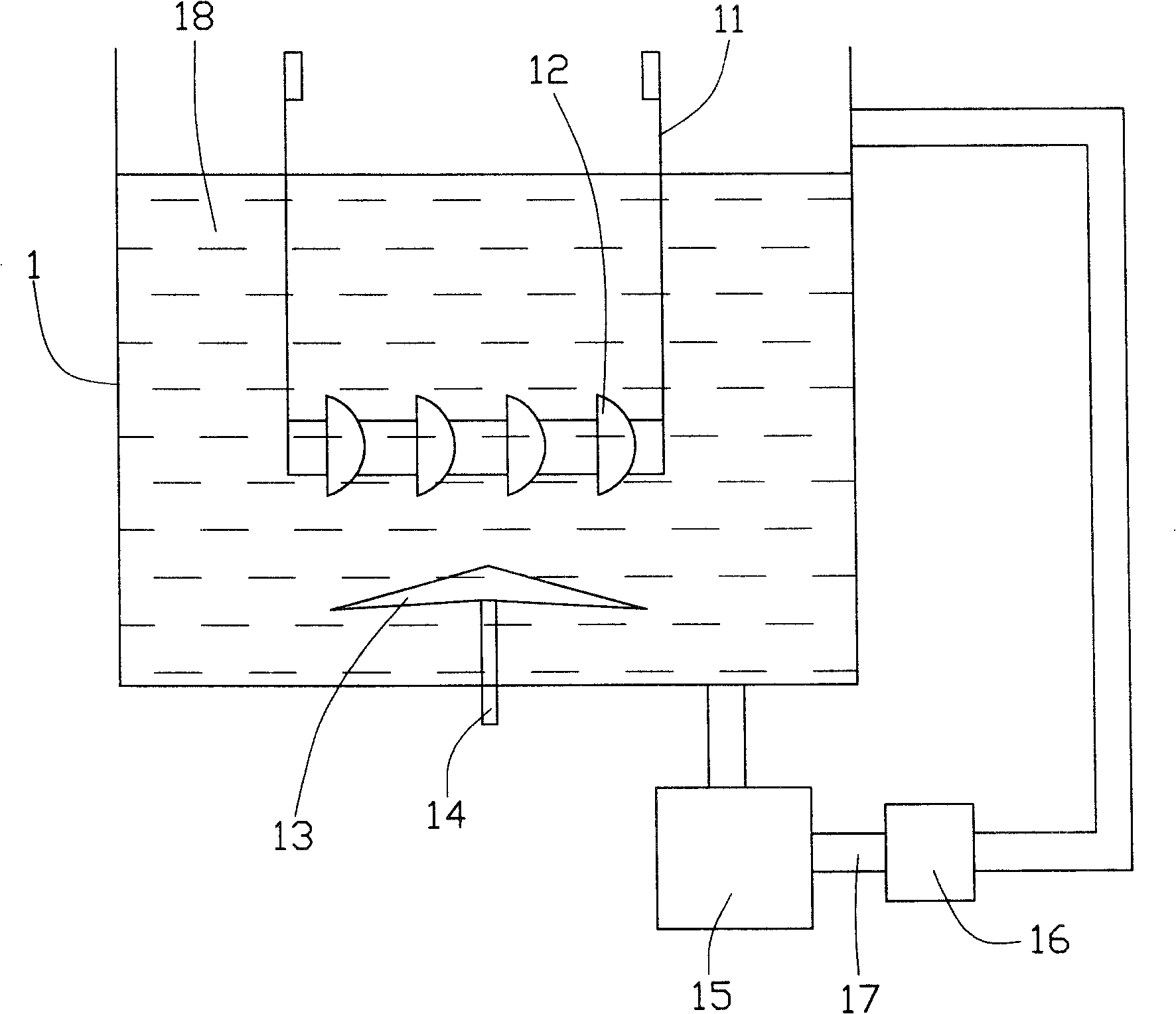

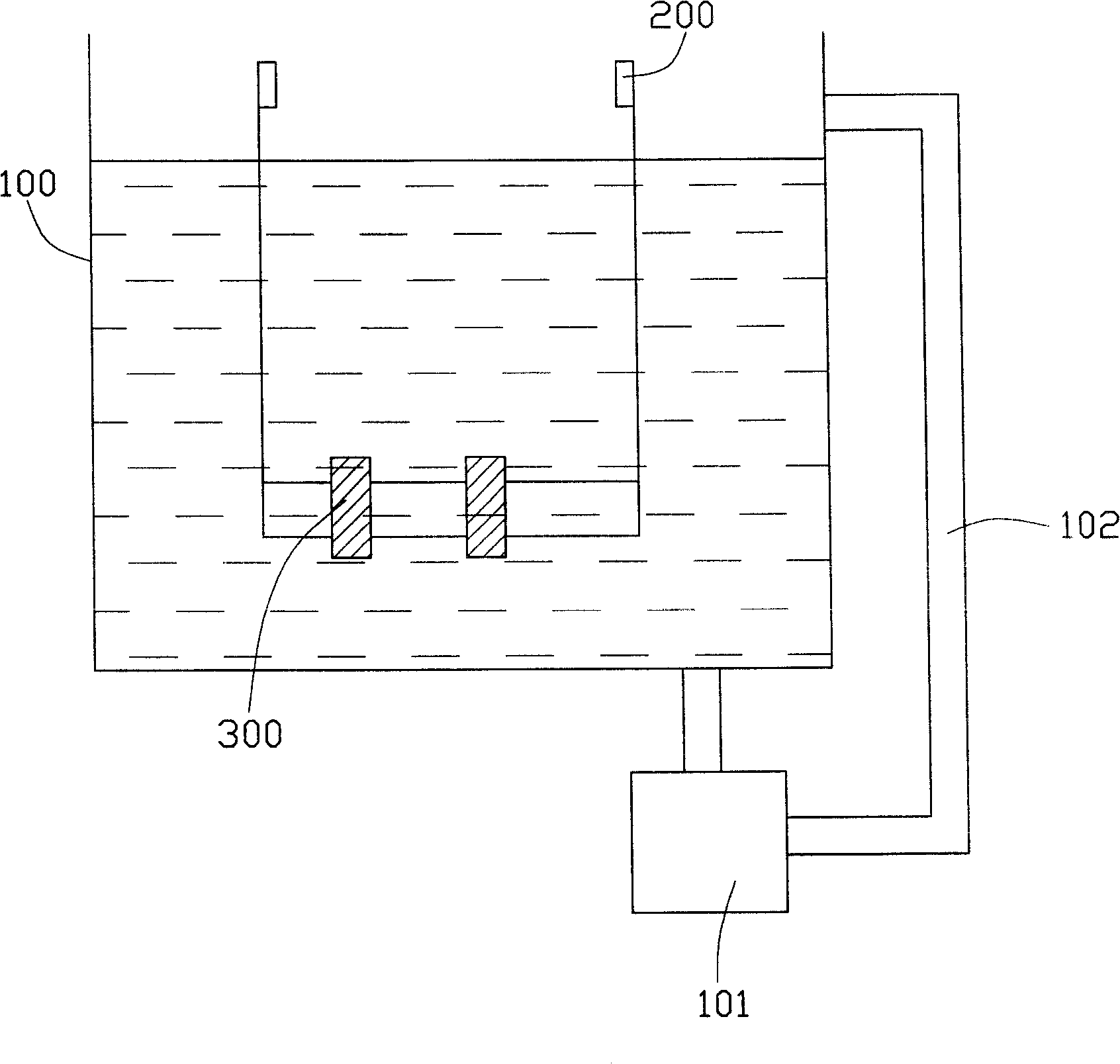

[0021] like figure 2 As shown, the first embodiment of the present invention is a cleaning device, and the components to be cleaned are lenses. The cleaning device includes a cleaning tank 100 , at least one hanger 200 , and at least one clamp 300 . Cleaning tank 100 is equipped with cleaning liquid, and its interior is provided with ultrasonic device (not shown in the figure), and its bottom is connected with a waste liquid processing device 101, and after the treatment, relatively pure cleaning liquid is introduced into cleaning tank 100 again through conduit 102 to regenerate use. The hanger 200 is arranged on the top of the cleaning tank 100 and can be controlled to move up and down. The clamp 300 is fixed on the hanger 200, and the lens to be cleaned is housed in the clamp 300.

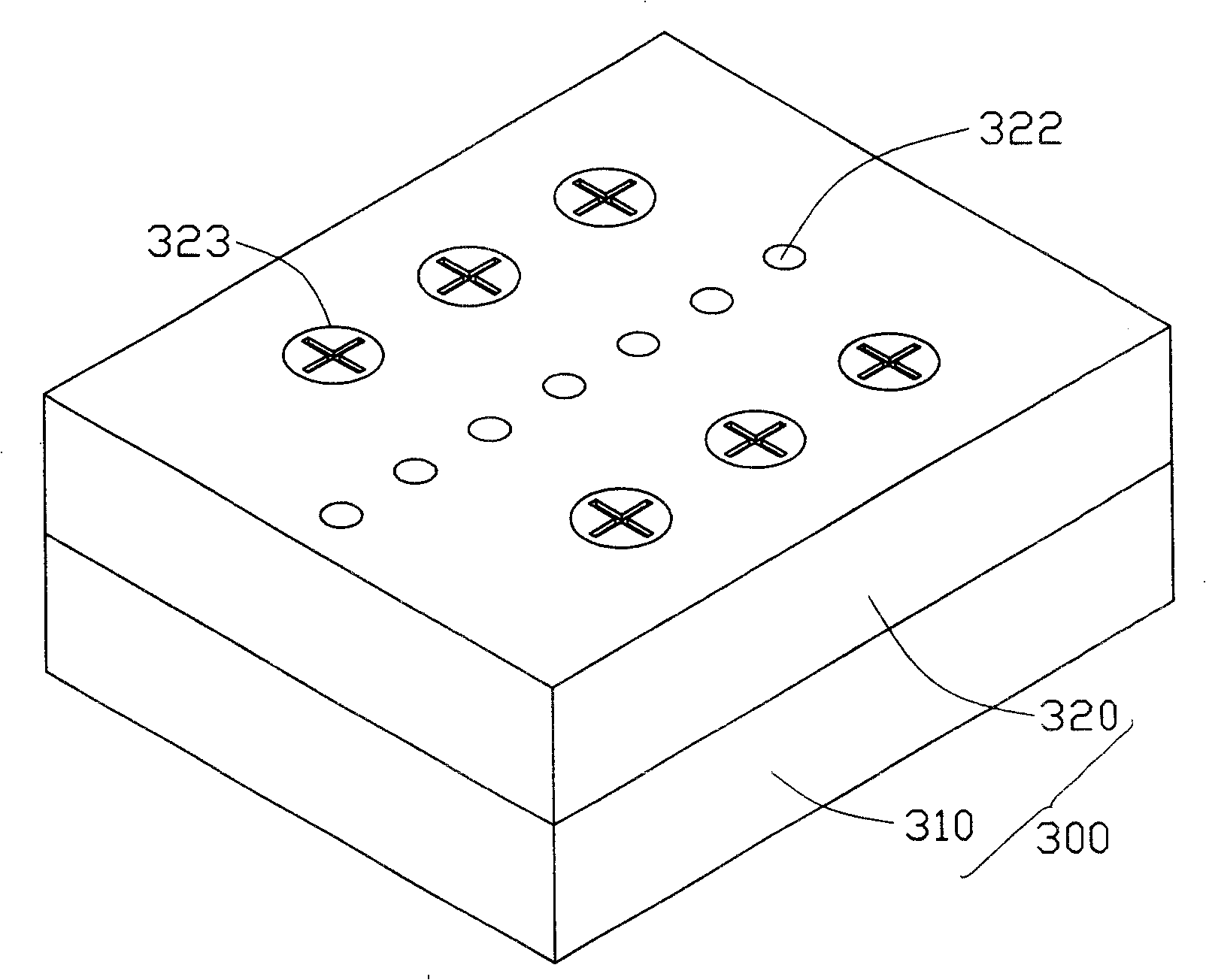

[0022] like image 3 As shown, the clamp 300 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com