High temperature aging test device for display panel

A display panel and high-temperature aging technology, applied in the direction of measuring devices, electronic circuit testing, measuring electricity, etc., can solve the problems of complex wiring, small operating surface of the test machine, and inability to achieve real-time replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

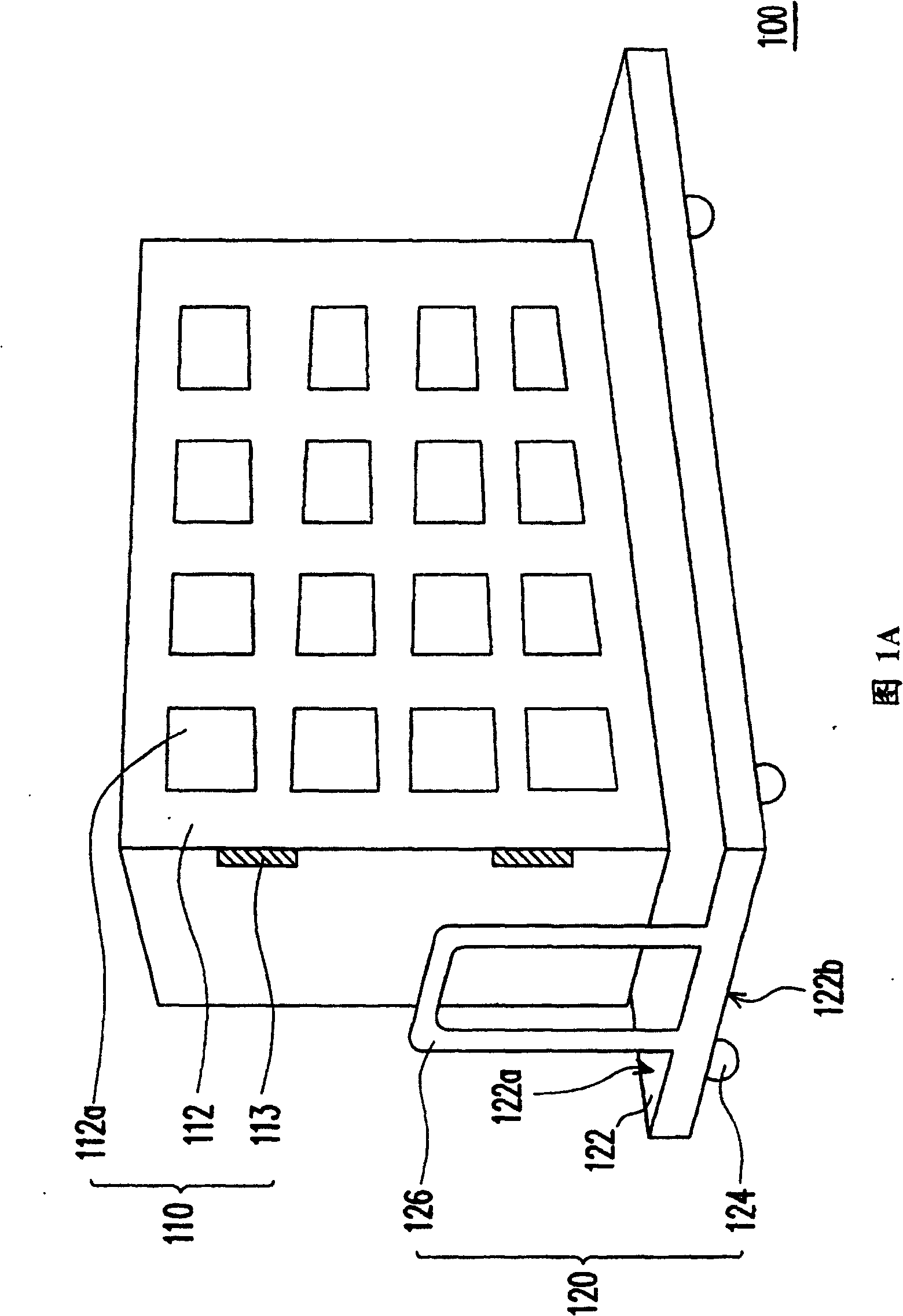

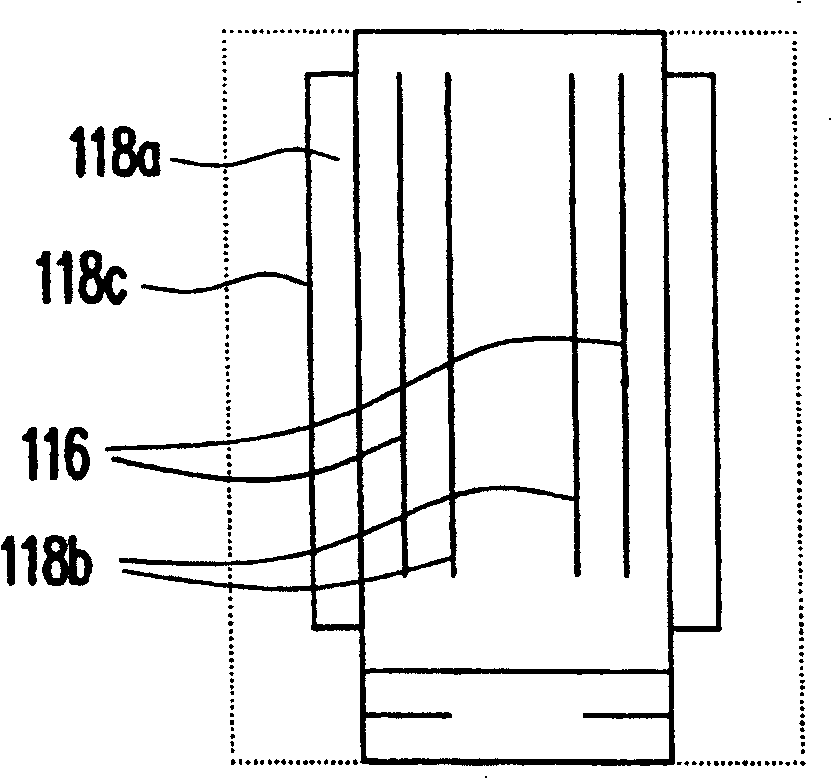

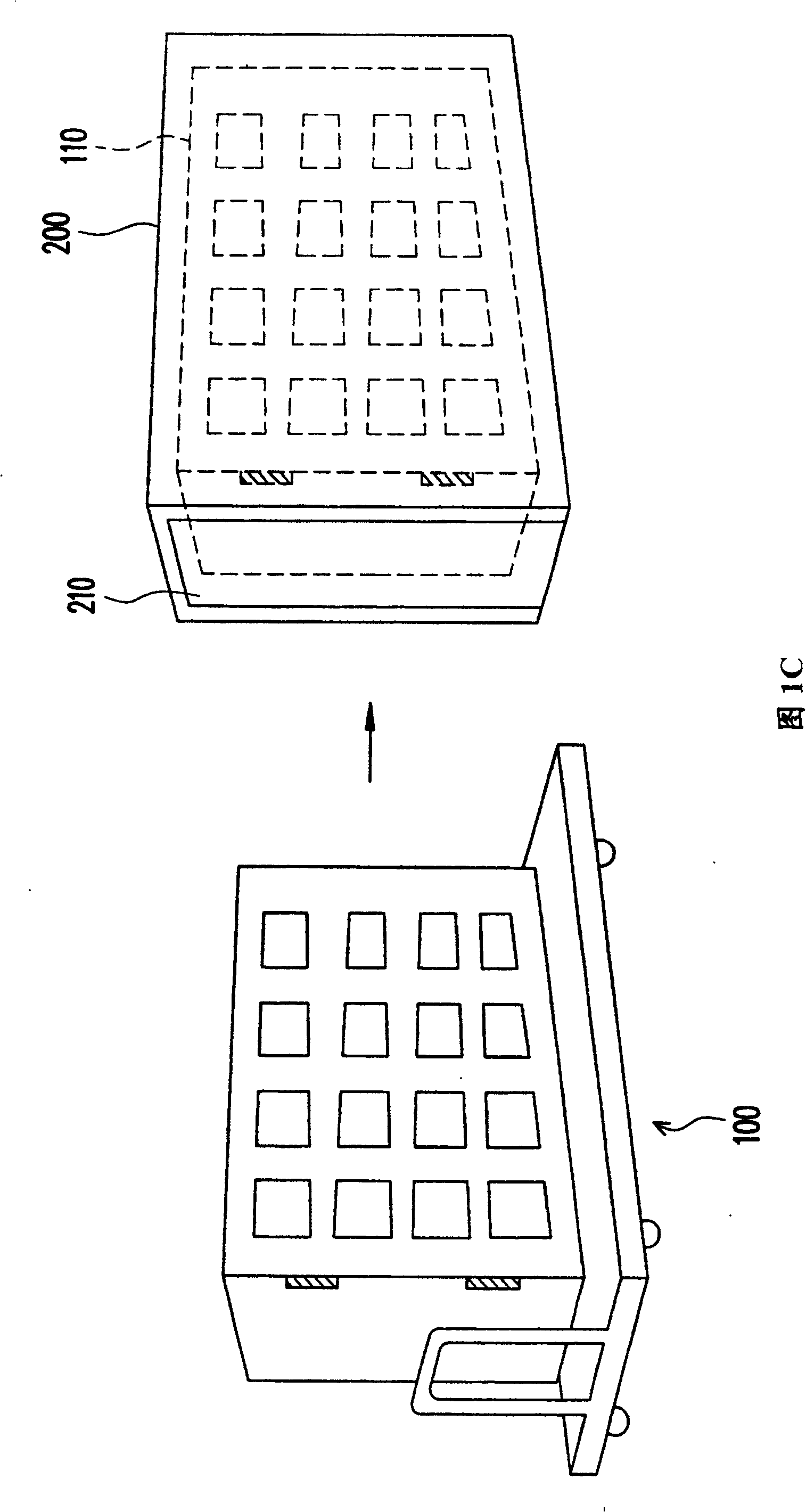

[0033] FIG. 1A is a perspective view of a test rack device for a display panel according to a preferred embodiment of the present invention, Figure 1B It is a top view of a test rack device in a preferred embodiment of the present invention, and FIG. 1C is a schematic diagram of a high-temperature aging test device of the present invention. Also refer to Figure 1A, Figure 1B And Fig. 1C, this test shelf device 100 comprises shelf member 110 and movable base 120, wherein shelf member 110 has side panel 112, and a plurality of test units 112a are arranged on side panel 112, and each test unit 112a It can be connected to a test panel, and a driving circuit (not shown) and a lamp 116 are provided on the shelf member 110 . In addition, the movable base 120 is used to support the shelf member 110, which for example includes a bottom plate 122, a plurality of sliding wheels 124 and a handle 126 that allows the tester to move the base 120, wherein the bottom plate 122 has an upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com