Easy assembling and disassembling connecting mechanism and its device

A technology that is easy to assemble and equip, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of large labor force, difficult to achieve automatic product assembly production cost, increase screw material assembly cost, lock screw assembly man-hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

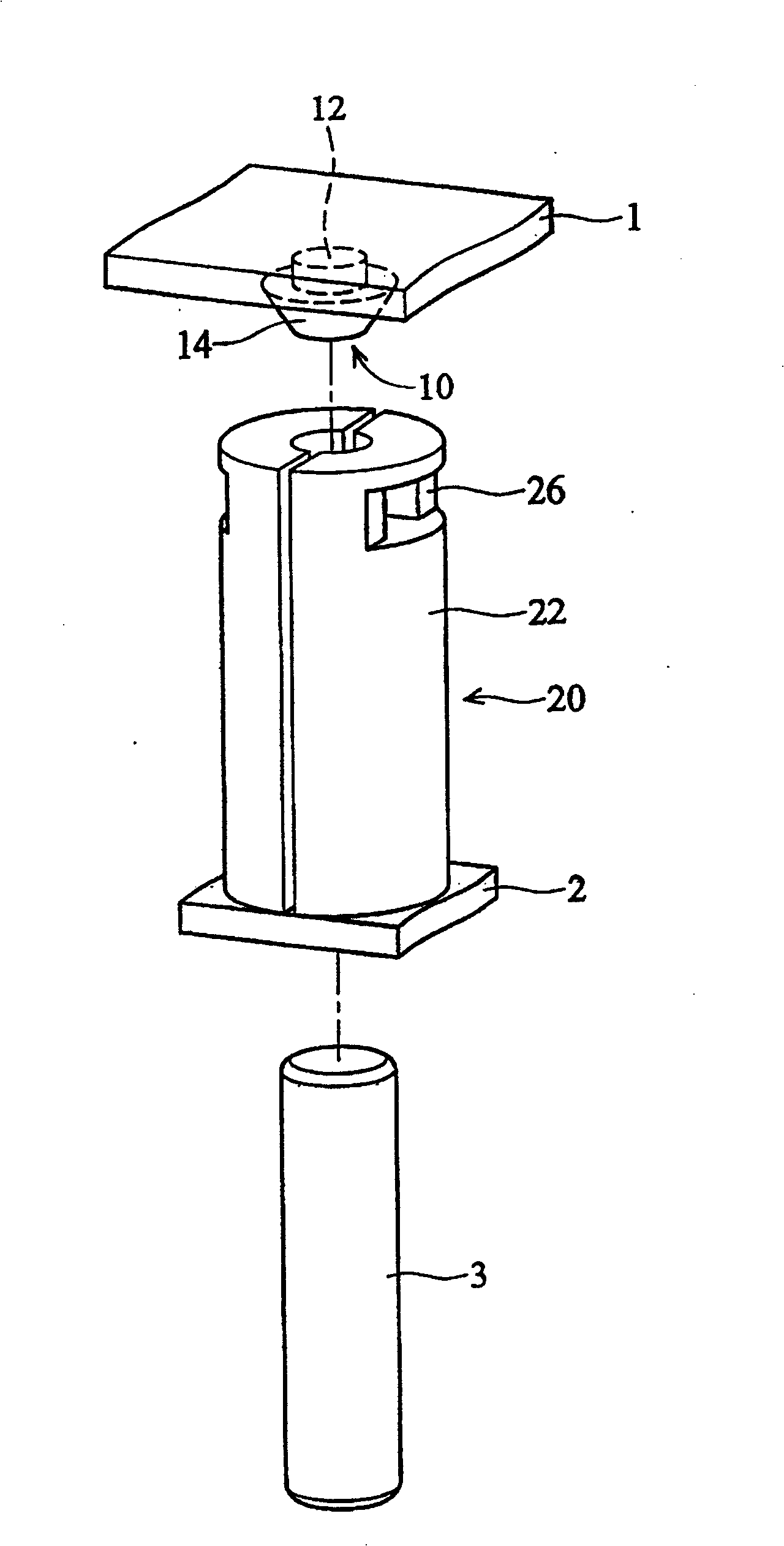

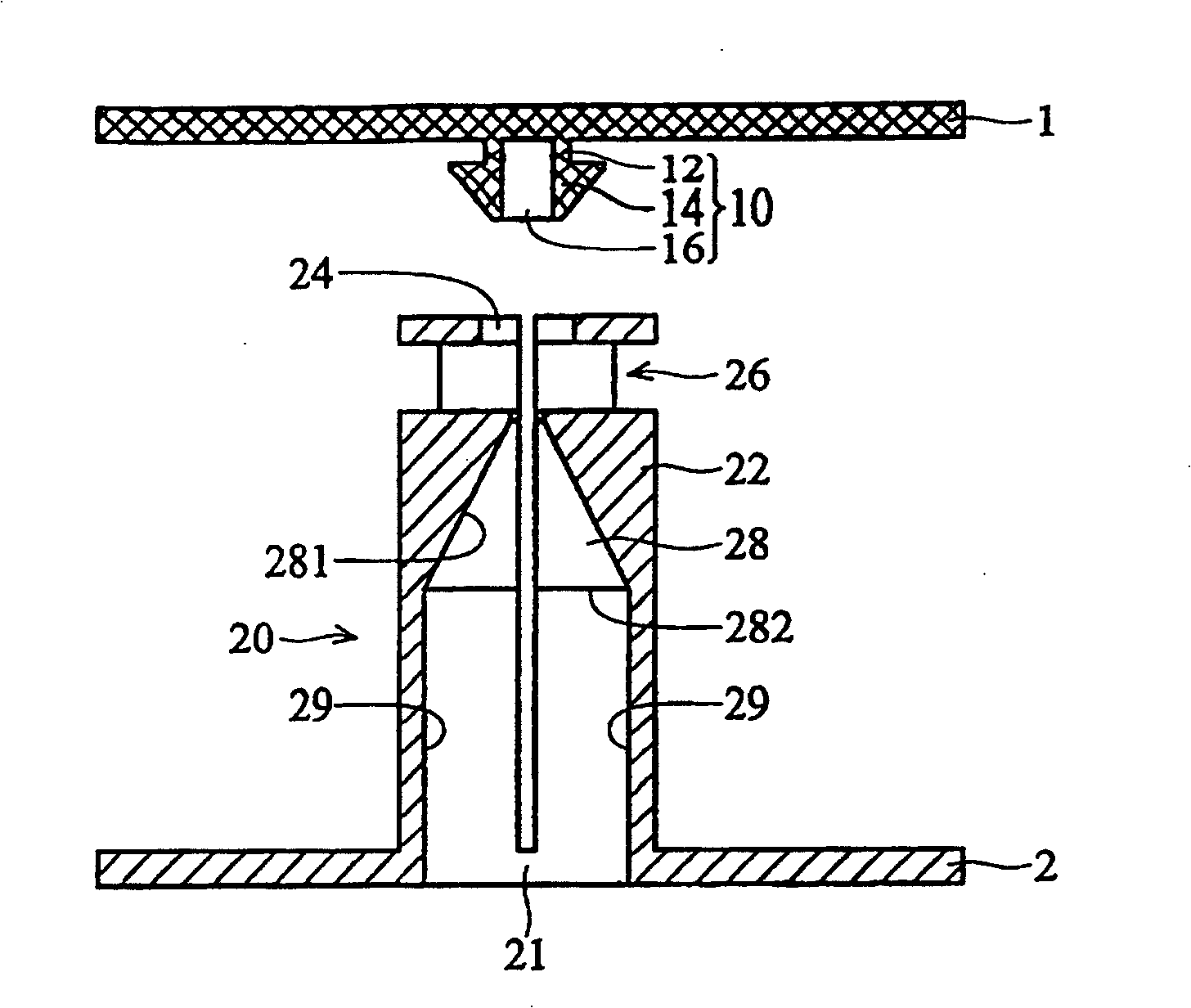

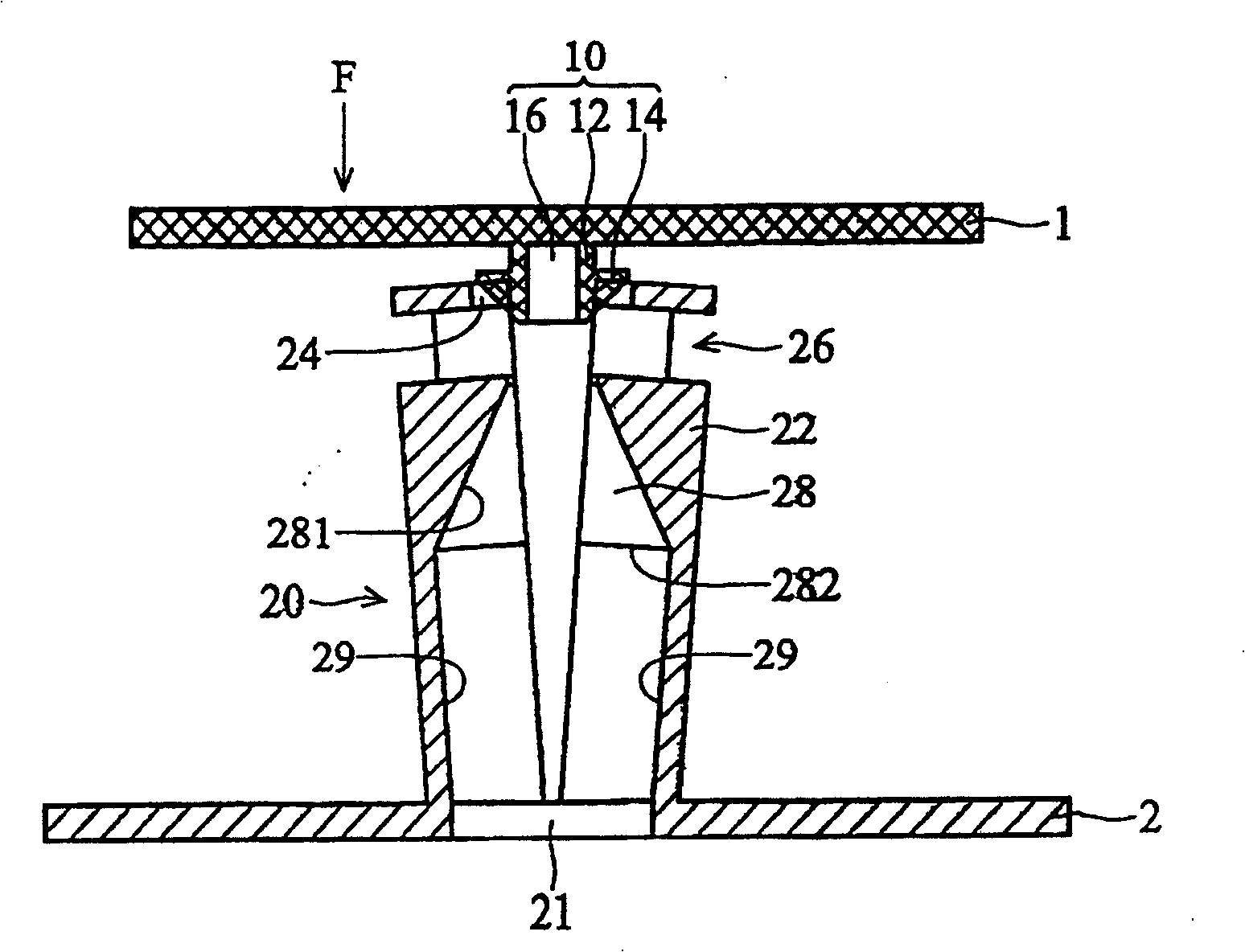

[0017] figure 1 It is an assembly diagram of the easy-to-assemble and disassemble connecting mechanism of the present invention, and Figure 2A for figure 1 sectional view. Such as figure 1 and Figure 2A The quick assembly and disassembly connecting mechanism shown is shown, through which the first housing 1 and the second housing 2 can be quickly connected, wherein the connecting mechanism includes a hook 10 and a fastening member 20 . The hook 10 is arranged on the first housing 1 and integrally formed with the first housing 1. The hook 10 has a first part 12 and a second part 14. The second part 14 passes through the first part 12 and the first part. The shells 1 are connected, and the width of a part of the second part 14 is larger than that of the first part 12 . In this embodiment, the second part 14 of the hook 10 is tapered, and there is a slot 16 in the center of the hook 10, passing through the first part 12 and the second part 14, so as to avoid the plastic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com