Single-phase motor and its stator winding and tie lines method

A stator winding and wiring technology, which is applied in the field of single-phase motors and their stator winding and wiring, can solve the problems of easy friction of wires, difficulty in arranging neatly, and low slot occupation rate, and achieve smooth winding and easy arrangement Neat and improve the effect of slot occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

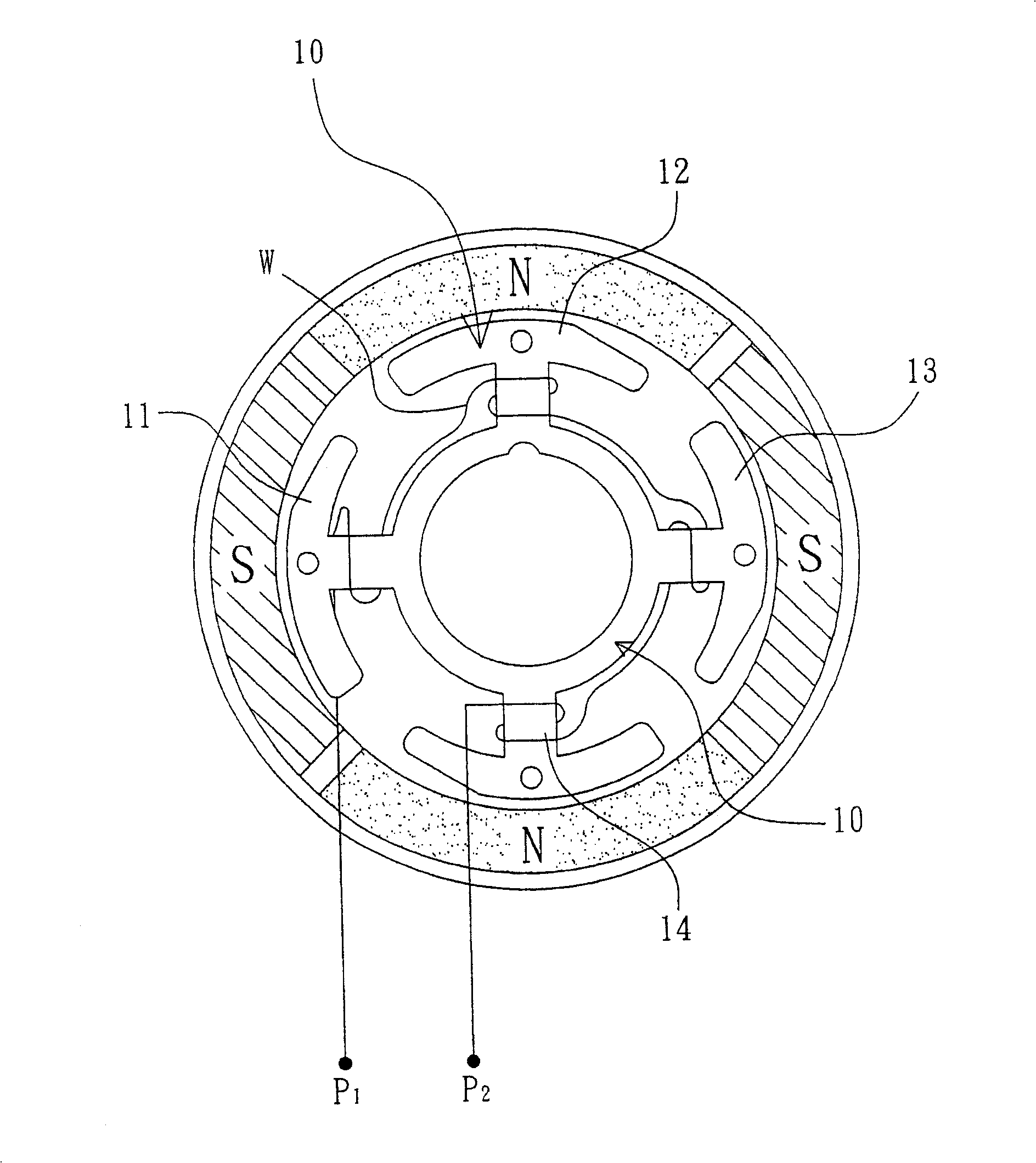

[0023] The single-phase motor and its stator winding and wiring method according to a preferred embodiment of the present invention will be described below with reference to related drawings.

[0024] First, please refer to Figure 3 to Figure 7 In order to illustrate the stator winding and wiring method and the single-phase motor of the first preferred embodiment of the present invention.

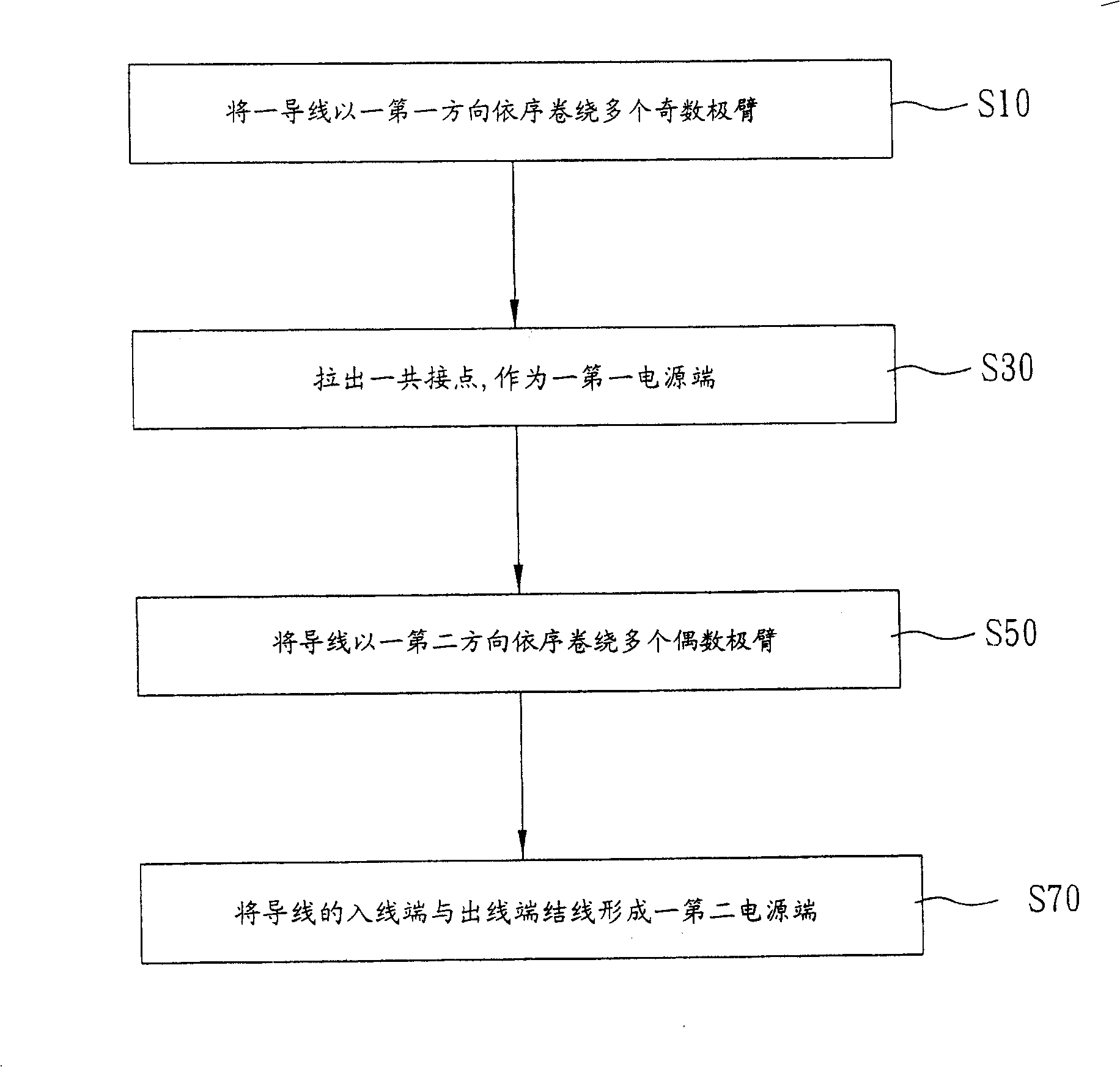

[0025] image 3 It is a schematic flowchart showing the stator winding and wiring method according to the first preferred embodiment of the present invention. Such as image 3 As shown, the stator winding and wiring method includes: sequentially winding a wire in a first direction to a plurality of odd-numbered pole arms (S10), pulling the wire out of a common contact as a first power supply terminal (S30), Sequentially winding the wires around a plurality of even-numbered pole arms in a second direction (S50), and connecting wire-in terminals and wire-out ends of the wires to form a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com