Multichannel high efficiency oil-well pump

An oil well pump, multi-channel technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of the pump efficiency of oil well pumps cannot be well exerted, it is not easy to popularize in a large area, and the downhole casing is damaged. To achieve the effect of reducing replacement, reducing elastic elongation, and reducing the probability of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

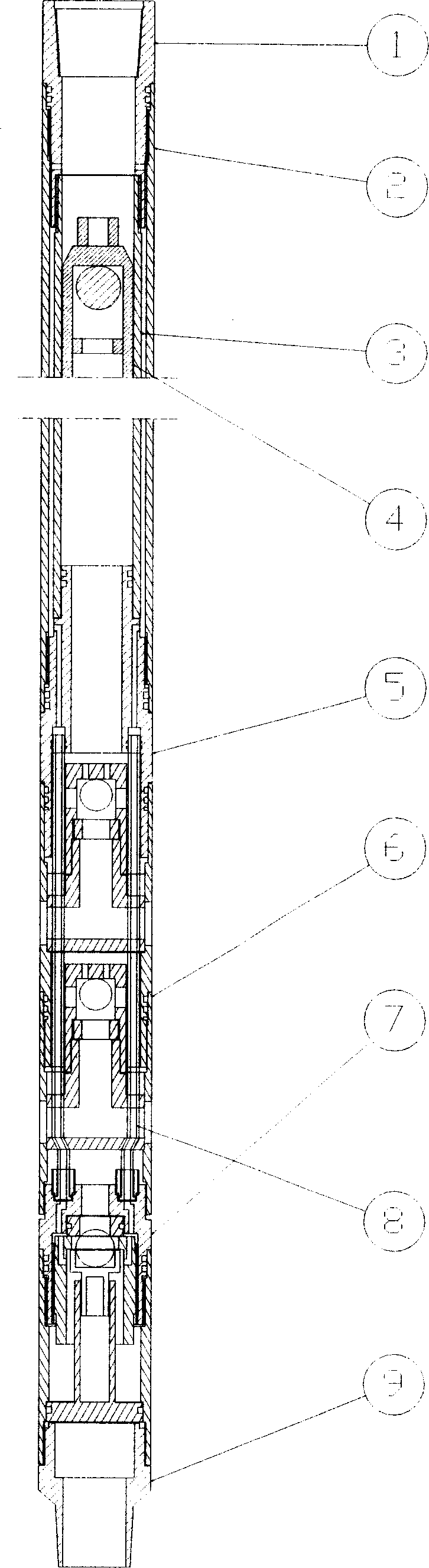

[0018] Example 1: The φ44 pump consists of an upper joint {1}, an outer cylinder {2}, a φ44 whole cylinder pump cylinder {3}, a φ44 plunger assembly {4} transition joint {5}, and a bridge type inlet of the tubular oil well pump. It consists of oil device {6}, liquid commutator {7}, copper pipe {8}, and lower joint {9}.

Embodiment 2

[0019] Embodiment 2: The φ57 pump consists of an upper joint {1}, an outer cylinder {2}, a φ57 whole cylinder pump cylinder {3}, a φ57 plunger assembly {4} transition joint {5}, and a bridge type inlet of the tubular oil well pump. It consists of oil device {6}, liquid commutator {7}, copper pipe {8}, and lower joint {9}.

Embodiment 3

[0020] Example 3: The φ70 pump consists of an upper joint {1}, an outer cylinder {2}, a φ70 whole cylinder pump cylinder {3}, a φ70 plunger assembly {4} transition joint {5}, and a bridge inlet of the tubular oil well pump. It consists of oil device {6}, liquid commutator {7}, copper pipe {8}, and lower joint {9}.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com