Strip lateral type light guide structure and surface source module

A light guide structure and side-firing technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problem of high cost of light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

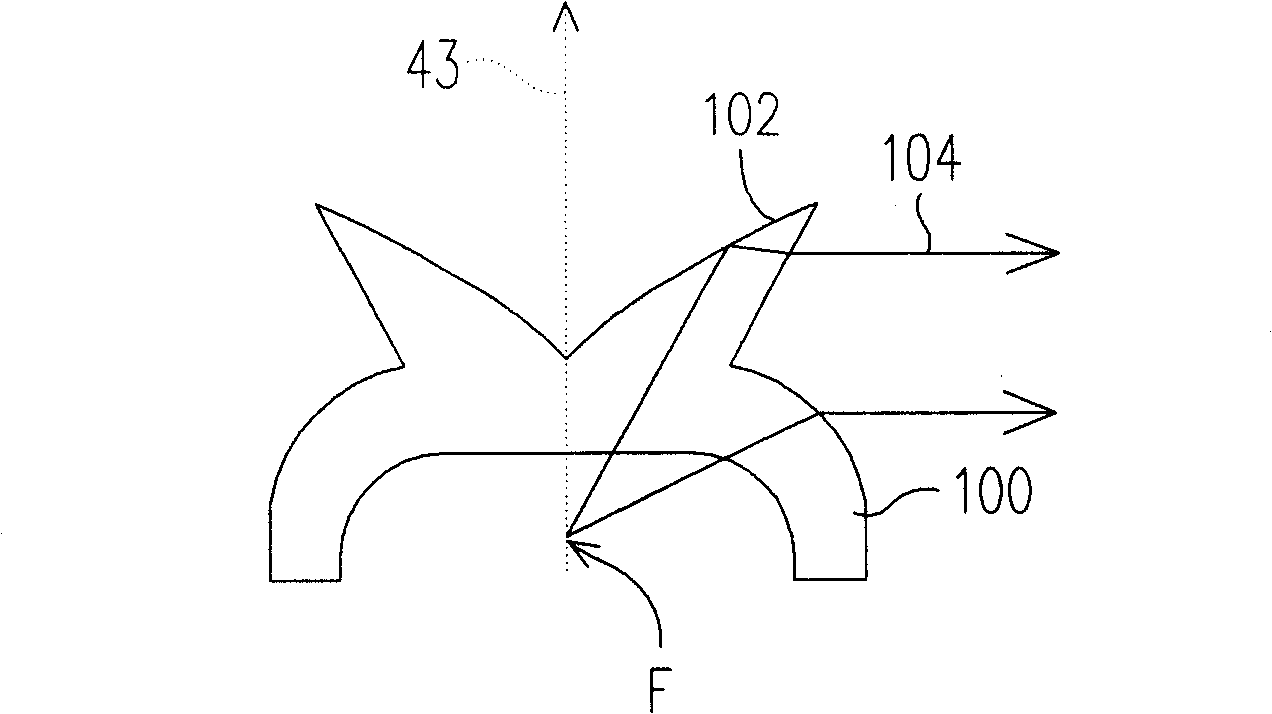

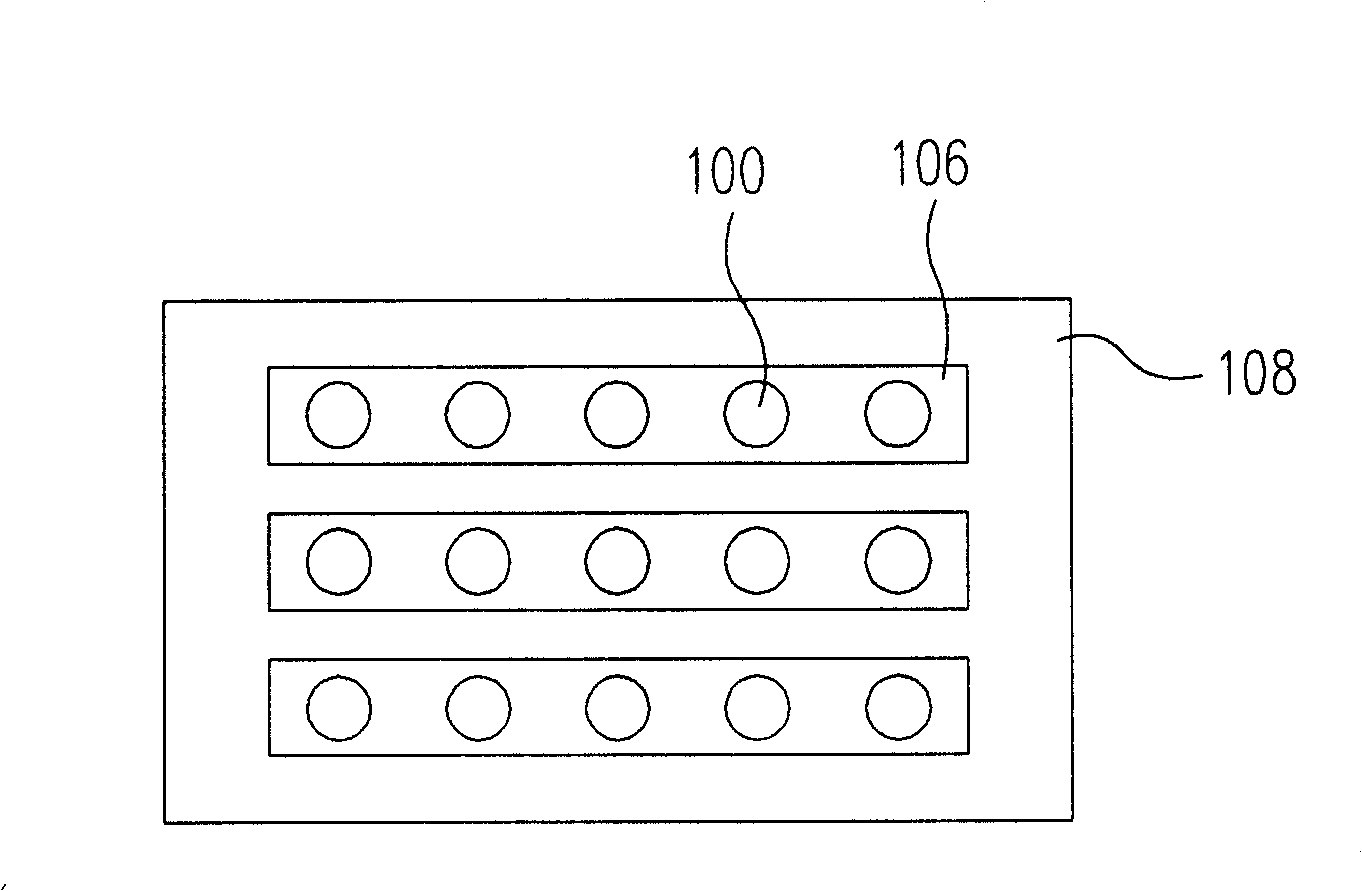

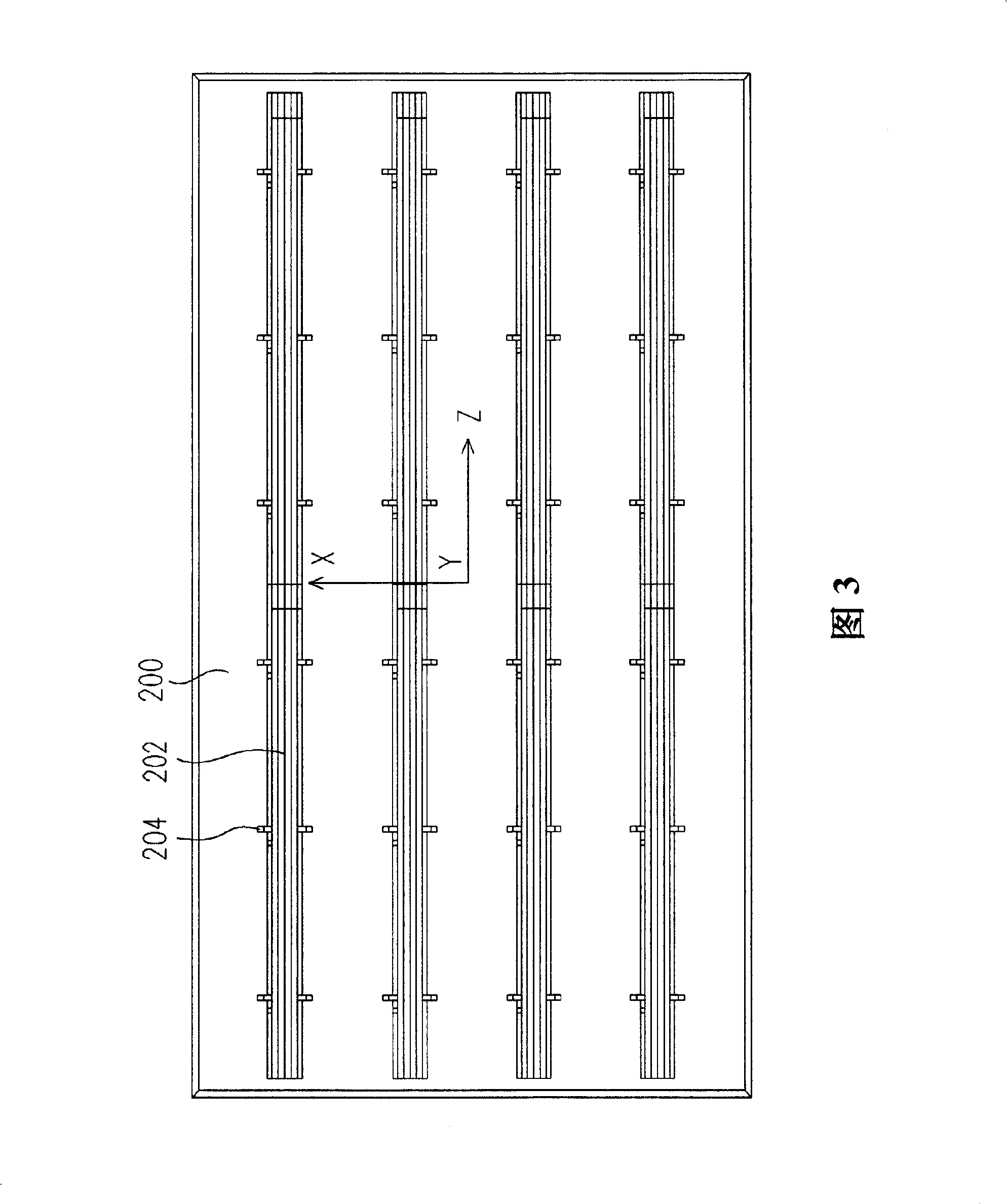

[0041] The strip-shaped side-firing light guide structure of the present invention changes the directional light source into a side-firing light source. This structure is especially suitable for large-scale planar light sources of LEDs as a light mixing module. This large planar light source module will include at least one light source, a strip-shaped side-firing light guide structure and a diffuser. This can at least make it easy to obtain a light source with uniform mixed light in a short distance, and has the characteristics of reducing cost and simple production.

[0042] At present, in the large-scale planar light source developed with LED light source, it is better to use total reflection and transparency to form a side-emitting light source for LED light source packaging design, but this packaging method will increase the cost and production complexity. Based on this factor, the present invention only needs to use a generally simple LED package, coupled with the strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com