Halogen incandescent lamp for motor vehicles

A technology for motor vehicles, incandescent lamps, applied in the field of halogen incandescent lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

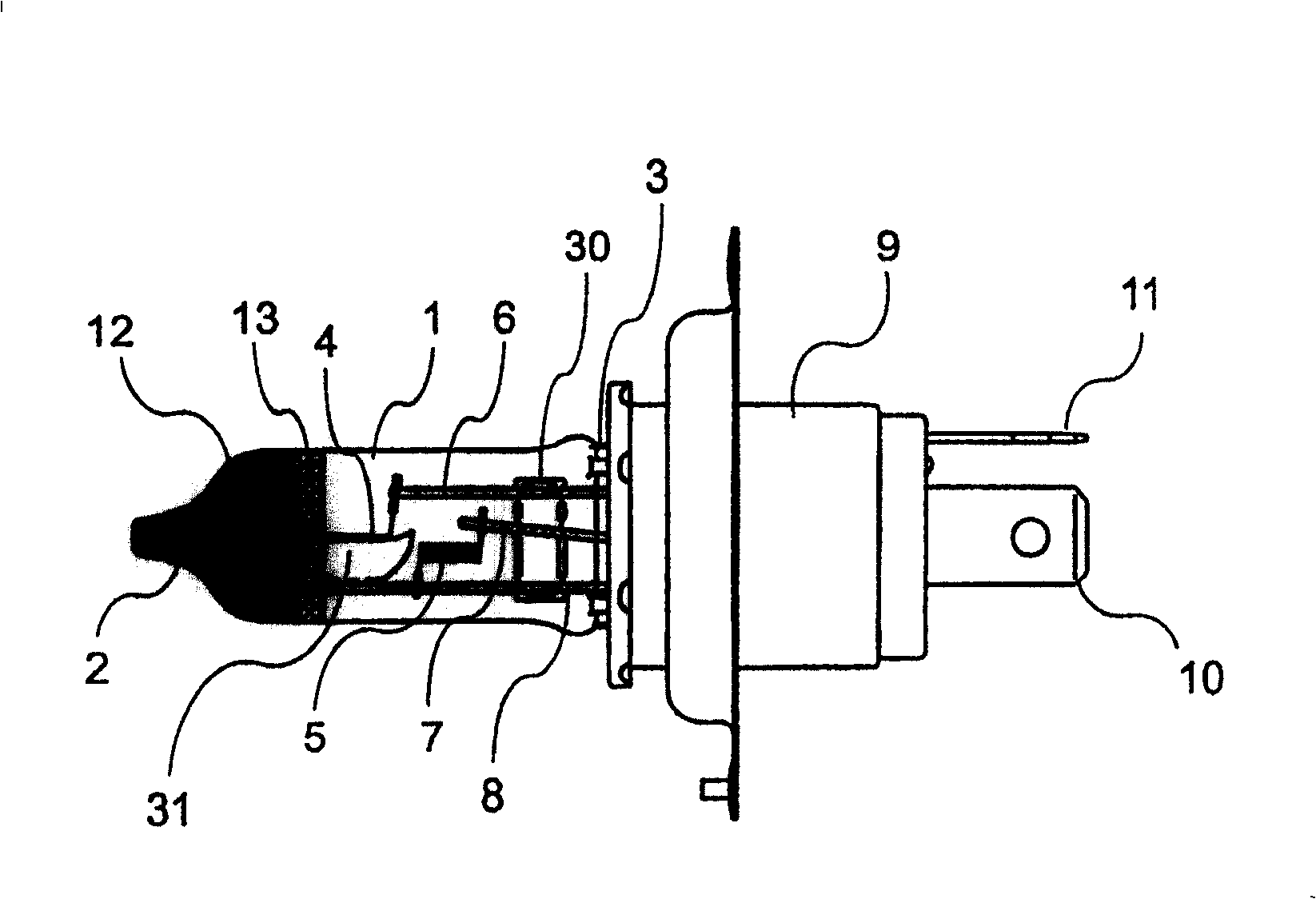

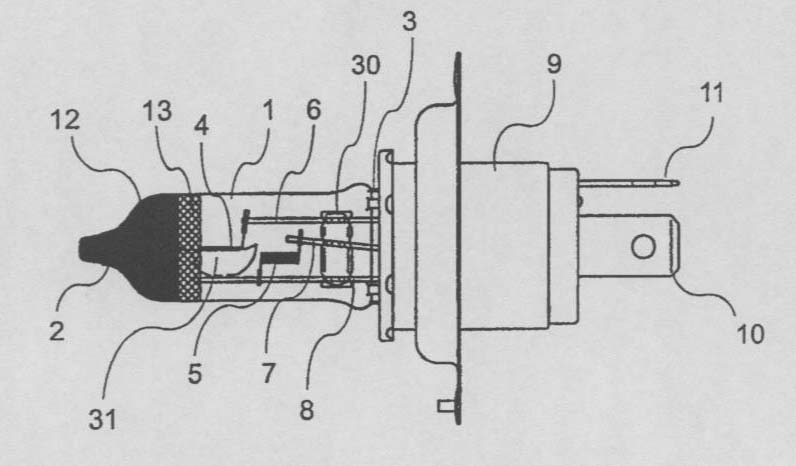

[0015] figure 1 Shown is a motor vehicle lamp of the type H4, which has a substantially cylindrical bulb 1 made of quartz glass. The bulb 1 has a closed end 2 provided with a light-absorbing coating 12 . Two incandescent elements 4 and 5 which are designed as tungsten coils are arranged in a bulb 1 which is filled with a halogen-containing gas. A passing light coil 4 is used to generate passing (low) beams, and a high beam coil 5 is used to generate high beams in motor vehicle headlights. The passing light coil 4 is connected to the power supply lines 6 and 8 , and the high beam coil 5 is connected to the power supply lines 7 and 8 . The supply wires 6, 7 and 8 are secured in a pinch seal 3 which seals off the other end of the bulb 1 in a vacuum-tight manner. Also in the bulb 1 is a fixing element 30 which stabilizes the respective relative positions of the supply lines 6, 7 and 8. In this way, the passing light coil 4 and the high beam coil 5 are in a certain position in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com