Printing clamp for printing circuit substrate

A technology of printed circuit substrates and fixtures, which is applied in the directions of printed circuits, printed circuit manufacturing, and assembly of printed circuits with electrical components. The effect of ink adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

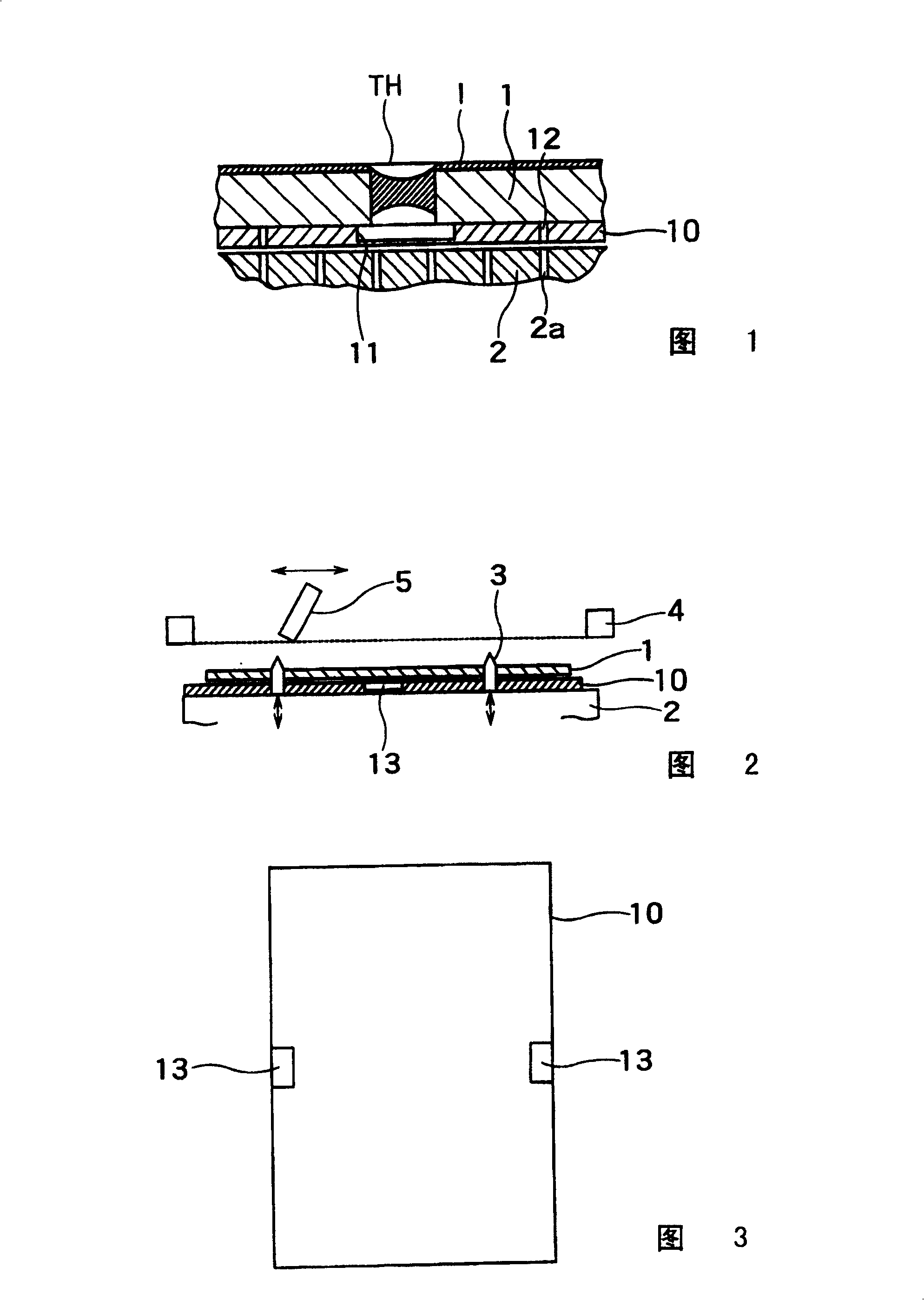

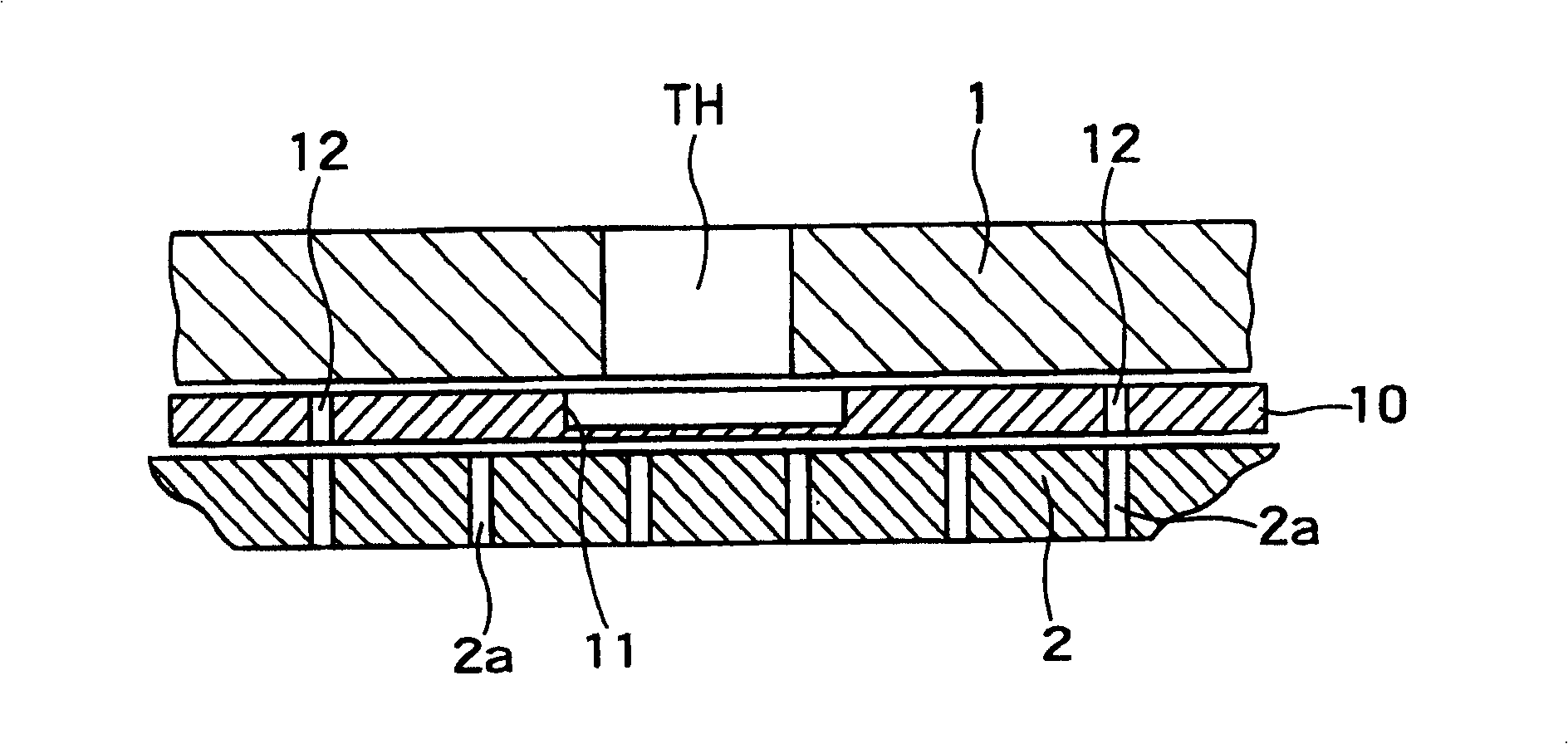

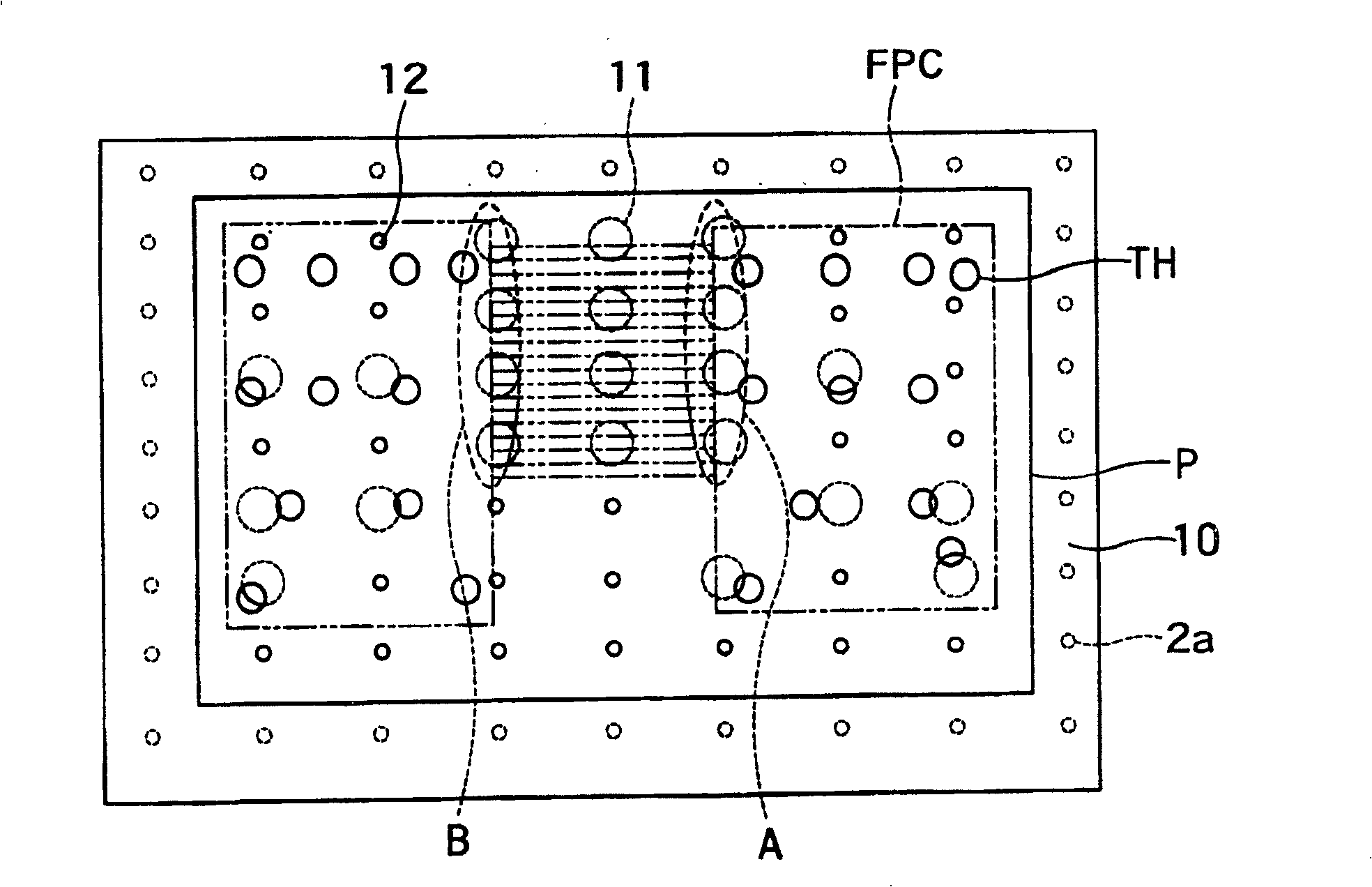

[0020] Fig. 1 is an explanatory diagram showing the installation of the printing jig of the present invention. Fig. 1 shows a cross-sectional view of the printed circuit board 1 placed on the printing machine head 2 by inserting the printing jig 10, which is an embodiment of the present invention. status.

[0021] As shown in the figure, it is in a state where ink I adheres to the vicinity of the through hole TH and blocks the through hole TH. Also, a spot facing as a non-through hole is provided in the printing jig 10 directly below the through hole TH. A hole 11 is formed to form an ink receiving part. A through hole 12 is provided in the printing jig 10 at a position deviated directly below the through hole TH, which communicates with the suction hole 2a of the printing head 2.

[0022] Thus, if the printed circuit board 1 is sucked by vacuum suction by the printing head, the printed circuit board 1 is sucked through the through hole 12 of the printing jig 10. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com